Avoid a Scissor Lift Accident! Uncover 7 key causes and pro tips on scissor lift safety

Scissor lifts are the main agents to solve problems anywhere in the construction sites, warehouses, factories, and also in the maintenance works going on all over the world. These versatile aerial work platforms materially help workers wit access to the upper part of a workplace while giving and sure-footedness and saving time by following the scissor lift safety protocols, which a mere ladder cannot do. Hence, the occurrence of scissor lift accident is very common in the work space.

Nevertheless, scissor lift accidents have emerged as the leading cause of risk that has been outshining the whole situation because of their advanced scissor lift safety features. The number of such scissor lift accidents is estimated to be between 300 and 400 per year, according to the CDC data. The death toll is roughly around 20 to 25 on average per year. These figures point to the necessity of an immediate response in terms of comprehending the typical reasons behind scissor lift accidents and, consequently, implementing preventive measures.

At Scissor Lifts, we are devoted to equipping people and organizations with the know-how that is indispensable for safe and efficient handling of these machines. If you are a construction worker, a maintenance technician, or a warehouse supervisor, the knowledge of the leading causes of scissor lift accidents will be a lifesaver.

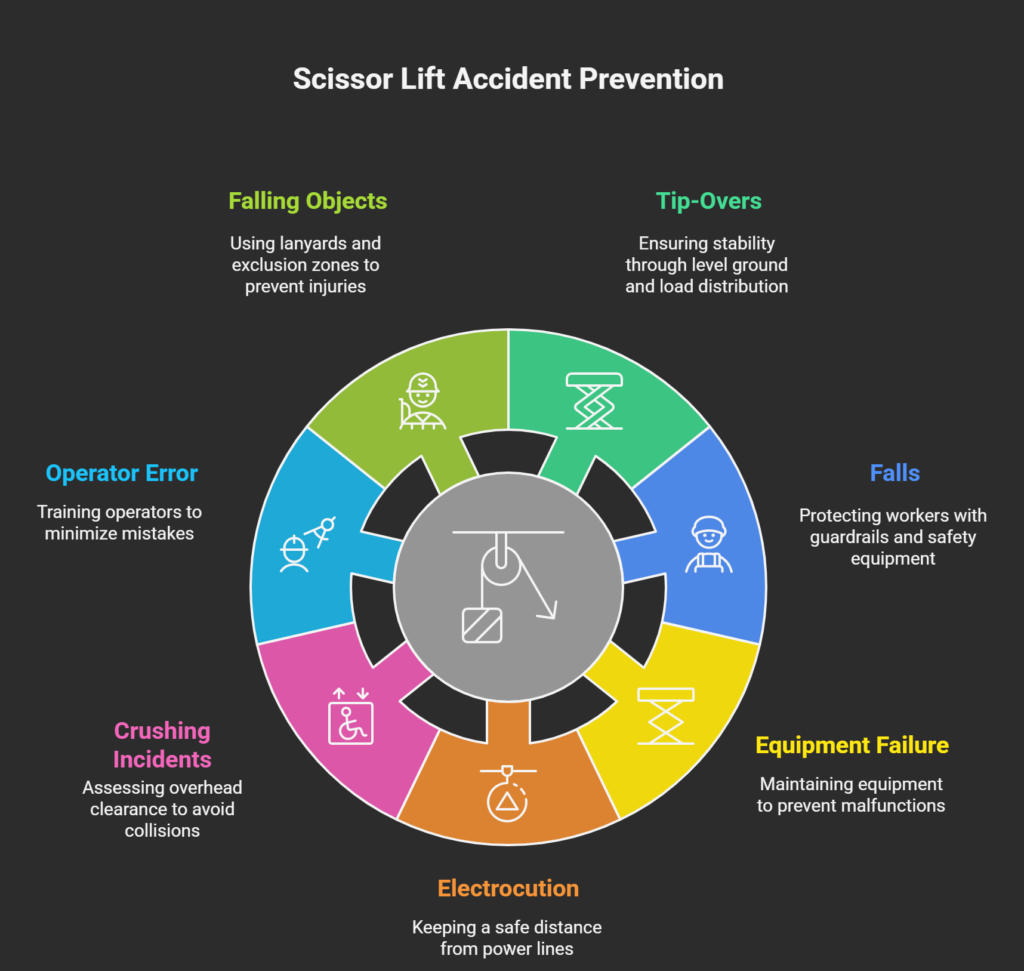

Top 7 causes of scissor lift accidents:

These top 7 major causes of scissor lift accidents provide respective practical prevention strategies for the best scissor lift safety protocol certified by OSHA regulations and industry professionals.

1. Tip-Overs and Instability Issues

Tip-over scissor lift accidents represent the largest proportion of deaths and severe injuries caused by scissor lifts across all industries. Mainly, these accidents happen when the shift of the machine’s center of gravity beyond its stability threshold causes the entire lift to fall over with such tragic consequences. Typically, tip-overs are on construction sites where uneven ground, weather conditions, and irresponsible loading that leads to bad working conditions are common factors.

Main Factors Leading to Tip-Overs:

- Uneven and Surfaces: Operating a scissor lift on a slope, incline, hole, or less stable ground is a sure way to risk tipping over. A rough-terrain scissor lift may be built for the outdoors, but it still has some limitations in terms of the maximum grade allowed.

- Incorrect Load Distribution: The situation when operators or materials are on one side of the platform, and workers are leaning too far beyond the guardrails, the center of gravity of the lift will change.

- Bad Weather Conditions: Until now, the most dangerous thing that can happen to an elevated scissor lift is being hit by strong winds that generate lateral forces, thus making the system unstable.

Prevention Strategies:

Ground always checks before setting up a scissor lift, ensuring not only the scissor lift safety but also the level and firm condition of the area. When concerning the maximum grade allowed, it is necessary to follow the manufacturer’s instructions. do not exceed the lift load more than the rated capacity, and if you have an outdoor work plan, check the weather forecast, and discontinue your work if the wind intensifies.

2. Falls from Elevated Platforms

The most common type of accidents is falls from scissor lift platforms resulting in a catastrophic injury, including major brain injuries, spinal cord damage, and death. It happens usually when the operator losing balance, support rails breaking or being absent, and colliding with an unexpected event like a vehicle that causes the lift to lose balance.

Primary Contributing Factors:

- Guardrails Deterioration or Removal: Guardrails are the main part of fall protection system on on scissor lifts. When they become defective, are taken off, or fail to meet requirements, the chance of falling increases considerably.

- Mishandling Scissor Lift Safety Gears: Despite the fact that OSHA regards well-functioning guardrails on scissor lifts as sufficient fall protection, in most cases, safety harnesses connected to specific anchor points are used additionally.

- Going Beyond the Platform Safety Boundaries: Employees willing to maximize their reach usually do it by standing on guardrails or by leaning far away from the safe part of the platform without realizing the consequences.

Prevention Strategies:

Inspect all components of guardrails, gates, and scissor lift safety bundles before use, and if any piece is damaged, it should be replaced immediately. Make sure that the platform gate is closed during the operation. Train workers to do the job within their comfortable reach and reposition the lift instead of overreaching. Put in place traffic control measures to prevent collision with scissor lifts.

3. Equipment Malfunction and Mechanical Failures

The contributions of mechanical failures to scissor lift accidents are very significant, they concern a range of problems such as hydraulic system failures, brake malfunctions, electrical issues, and structural defects. These issues might suddenly arise in the middle of operation leaving the operator without a hint of and thus they are rare. The root of scenarios of equipment malfunction is usually poor maintenance, deferred repairs, or operating the equipment beyond its designed service life.

Primary Contributing Factors:

- Hydraulic Failures: Broken machinery parts accompanied with hoses and fluid that is not pure can bring about platform rapid drop or complete hydraulic failures in one go.

- Brake and Control System Issues: The situation of defective brakes, control system faults, and electrical failure combined with each other could altogether convince the operator to lose the control over lift movements.

- Worn or Damaged Components: Everyday wear of the motor gears, platforms, and tires made of rubber, and safety sensors from our side if not maintained properly will lead to the degradation of scissor lift safety in the equipment.

Prevention Strategies:

Get the full preventive maintenance in place, as recommended by the manufacturer for the service intervals, and follow it through. Daily thorough pre-operation inspection should also be part of your regular regime. Look out for situations like hydraulic leaks, damaged wires, worn tire, and unusual noises. Make sure no one is allowed to operate the scissor lift that shows signs of mechanical faults until a professional technician resolves it.

4. Electrocution from Power Lines

Electrocution is among the most serious types of dangers that come with scissor lift operations. It is mostly a problem with the nature of outdoor environments where there are overhead power lines. The contact with live electrical wires happens when the arrival of the power lines to the platform, boom sections, or the operator is direct. Also, the electricity arc can happen when the gap is not enough for the electric current between the two points without the contact. Most times, these accidents cause the death of the victim eventually leading to cardiac arrest resulting from electrocution and serious burns.

Primary Contributing Factors:

- Poor Site Assessment: Ignoring the need to pinpoint and mark the locations of the overhead power lines before starting work can easily lead to coming into contact with the lines.

- Short Clearance Distances: As a worker in an area with overhead power line nearby, it is of paramount importance to keep the legally required minimum clearance to avoid any possible contact and electrical arcing.

- Unawareness of Electrical Hazard: Operators who don’t know the electrical hazards and proper clearance distance are the most likely to commit fatal mistakes.

Prevention Strategies:

A thorough site check before commencement of work is a must as it enables workers to locate and mark overhead power lines. Always treat power lines as if they are live and energized. Keep a minimum distance from the power lines as recommended by OSHA – usually about ten feet for lines rated 50kV or less. Get in touch with utility companies if you want them to turn off the power supply while you are working next to the electrical source.

5. Crushing and Entrapment Incidents

Crushing and entrapment accidents mainly involve operators who have been locked in between the scissor lift platform and stationary objects such as overhead beams, the ceiling, walls, or other structural components. The scenarios turning the unfortunate workers on the ground, who can be crushed as a result of the lift tipping over or collapsing, are also among the entrapment incidents. Usually lack of hazard awareness, incorrect positioning, distracting the surroundings are some of the reasons for entrapments that have been dominant among the operators.

Primary Contributing Factors:

- Overhead Obstacles: The most common sources of overhead crushing are coming from such like the ceilings, beams, pipes, and any other building elements that the platform gets raised into or goes under these fixed objects.

- Poor Clearance Planning: The negligence of the total height of the scissor lift, operator, and materials, will cause that there are no enough clearances left.

- Moving Platform Hazards: The scissor mechanism itself creates pinch points between moving components during raising and lowering operations.

Prevention Strategies:

Be sure to do a proper overhead hazard assessment prior to placing any scissor lift making exact clearance measurements and marking up the location of danger that is not safe to be near. The total height should be taken into consideration including the fully raised platform, the operator’s height, the materials, and a safety margin. Train operators to be diligent in scanning their surroundings for any overhead obstacles and thus make it a habit. Also, set up a separate area, safe for the ground workers, where they cannot be hit by falling objects from the platform.

6. Operator Error and Inadequate Training

Mishandling by humans continues to be a major factor in scissor lift faults, errors comprising inabilities to handle the operation methods, poor judgment, deliberate safety violations, and inadequate hazard recognition. Most of such operators are not sufficiently trained before being given the task of scissor lift operations, while a small percentage becomes complacent with time. OSHA puts up a strong case for a thorough course on the hazards and correct operation techniques of scissor lifts, yet the remaining training gaps perpetuate the issue of accidents further.

Primary Contributing Factors:

- Site-Specific Training Deficiency: A generic training program does not prepare the trainees for the particular hazards that might exist at different locations.

- Complacency and Safety Shortcuts: Inexperienced operators sometimes take dangerous shortcuts like standing on guardrails or exceeding rated capacities.

Prevention Strategies:

Give a full OSHA-compliant training on areas like the operation of the lift, scissor lift safety devices, hazard recognition, and emergency procedures before letting an operator work independently. Hands-on practical training using the specific scissor lift models that the operators will be handling is a good way to achieve this. Make refresher training a regular event and set the bar for competency by practical tests for those attending the sessions.

7. Falling Objects and Struck-By Hazards

One of the most dangerous situations of a drop is that they can cause injuries to the rigging workers while they are up in the lifter and the injuries can be so severe as to cause the death due to negligence of scissor lift safety measurements.

Besides the damage that falling objects can cause to the body, they can also detriment vehicles and machinery, and scissor lifts can be damaged in this way. The latter situation can be the cause of it being inoperable and hence, tip-overs or the same accidents can be happening for a second time.

Primary Contributing Factors:

- Unsecured Tools and Materials: When the uplift moves or shakes equipment and tools that are not firmly fixed on the platform can easily be flung off.

- Overhead Work Activities: When work is done at several heights at the same time,] the above materials can drop down and hit operators below.

- Poor Housekeeping Practices: Platforms that are filled with left-over materials and are poorly managed are the sources of falling objects during the operations.

Prevention Strategies:

All tools and materials should be secured by the use of tool lanyards, storage bins, or platform tie-downs. Exclusion zones should be established as safe places both for workers being on the platform and those being under it. Hard hats should be worn by every person in an area where work at a height is taking place. Besides that, platforms need to be in a good condition meeting all the scissor lift safety protocol, properly arranged and the work should be coordinated if different levels are involved.

Summary: A Comprehensive Scissor Lift Safety Culture

Knowing these seven major causes is not enough for the prevention of scissor lift accidents. What is needed, instead, is a full proactive and comprehensive approach that is made up of correct equipment choices, rigorous maintenance programs, thorough operator training, strict compliance with OSHA, and a workplace culture that puts safety higher than the pressure of productivity.

| Scissor Lift Accidents Type | Primary Prevention Strategy | OSHA Requirement |

| Tip-Overs | Level ground assessment, proper load distribution | Stable ground, adherence to load limits |

| Falls | Intact guardrails, proper safety equipment use | Fall protection for work above 6 feet |

| Equipment Failure | Regular maintenance and daily inspections | Proper equipment maintenance |

| Electrocution | 10-foot clearance from power lines | Minimum approach distance compliance |

| Crushing Incidents | Overhead clearance assessment, operator awareness | Overhead hazard evaluation |

| Operator Error | Comprehensive training and certification | Required operator training |

| Falling Objects | Tool lanyards, exclusion zones, PPE | Hard hat requirements in hazard zones |

Every worker has a right to go back home safe, and that is what we at Scissor Lifts stand for. The scissor lift accident rates involving the use of scissor lifts can be reduced significantly through the implementation of these prevention methods, the performance of regular safety audits, and the continuous advance of scissor lift safety provisions.

FAQ – Scissor Lift Accident

What is the most common type of scissor lift accident?

Tip-overs are the most common type of scissor lift accident, particularly in outdoor environments. The accident in this case is due to the lift’s center of gravity shift resulting from uneven ground, incorrect load distribution, or bad weather. Falls from elevated platforms are the leading cause of injuries and fatalities across all industries.

Do you need to wear a safety harness on a scissor lift?

According to OSHA, if the guardrails meet the standards and are kept in good condition, there is no need for a scissor lift safety harness. Nevertheless, many safety experts are of the opinion that harnesses fixed to the designated anchor points within the platform should be worn for extra safeguarding, especially in high-risk environments or adverse conditions.

How often should scissor lifts be inspected?

Every time before usage, scissor lifts are to be checked for damages by the current user or the next shift as well as when there is a new operator. The pre-operation inspections should include the check of the condition of the guardrails, hydraulic system for leaks, tires, and temporary visible damage. Besides that, thorough maintenance inspections should be held periodically following the manufacturer’s recommendation.

What is the minimum distance you should maintain from power lines when operating a scissor lift?

OSHA puts up a requirement for workers to keep a safe distance of at least ten feet away from power lines with 50kV or less capacity. Further distancing will be required in case of higher voltage carrying lines. It is also important to note that power lines are alive and energized even though they look dead.

Can a scissor lift be driven with the platform raised?

It might be possible for a few minor maneuvers to be done with the scissor lift slightly raised, but this should definitely be done slowly and with caution only on level, stable, and obstacle-free surfaces. Always check your particular model’s user manual for the limitations in that case because different models have different requirements.

What training is required to operate a scissor lift?

OSHA puts the onus on employers to provide in-depth training to the prospective scissor lift operator, which should cover how a scissor lift works, scissor lift safety recognition of hazards, limitations and procedures in case of emergency. Training should comprise classroom instruction and practical experience with the particular models.

What should you do if a scissor lift tips over?

In the case of a tip-over, operators are recommended to stay put on the platform and grasp the guardrails with all their might as opposed to attempting a jump for clearance. The probability of injury is increased dramatically by jumping. In the case of a properly secured safety harness that is attached to platform anchor points, the harness will act as a scissor lift safety device and hinder any unintended ejection.

If you are looking for more information on scissor lift accidents, scissor lift types, scissor lift safety protocols, or industry best practices, you may want to check out at https://scissorlifts.org/. Till then, stay updated, stay safe, and carry on with your work in a confident manner.