The Ultimate Outdoor Scissor Lift Guide: Mastering Seasonal Operations for Maximum Efficiency

The use of heavy equipment for outdoor operations always implies certain risks and changes, which managers, supervisors, and equipment operators should always be aware of to properly adapt outdoor scissor lift operations not only to keep the project’s productivity on track but for thoroughly ensuring safety and equipment durability.

Besides their compactness and better handling, a rough terrain scissor lift still has its limit when it comes to the operating conditions. Heat, for example, affects the cooling systems while cold weather depletes the battery power drastically and also makes the hydraulic fluids less efficient.

This extensive manual offers you a detailed overview of the seasonal changes and their effects on outdoor scissor lifts. No matter if you are struggling with the muddy ground of spring, dust filled days of summer, windy afternoons in autumn, or with extremely cold winter conditions, being equipped with the right ideas at the right time is the key to success.

If you follow this set of instructions, you’ll be able to raise your team’s safety standards while lowering the risk of breakdowns and saving a considerable amount of machine repair costs. So, here we go, year-round performance optimization and getting the most out of yours outdoor scissor lift investment, the weather won’t be your excuse anymore.

Spring: Handling the Melting and Wet Grounds

Temperatures in spring really do get milder with the setting of the sun, but for heavy machinery operators it means welcoming the unpredictable. Moisture is the main issue here—when the snow melts and spring rains come, the result is usually muddy and slippery grounds, which are the major factors detracting the stability of an outdoor scissor lift.

Beneath the ground that was rock solid and frozen in winter lies now soft and unstable soil, elevating the risk of the machine tipping over. In addition, the combination of high humidity and continual raining may bring electrical problems if the equipment waterproofing and inspection are not properly done.

That’s why, during the season, most of the attention in the maintenance and operation should go to traction and stability of the machine on the ground. Ground conditions are very important to watch; if the wheels are submerged through the ground, it can lead to serious accidents.

It’s also the ideal moment to do a machine post-winter check for any damages arising from the severely cold winter. You ensure a smooth path ahead by solving these problems beforehand.

Assessment of Ground Stability:

- Always do a walk-around to see the terrain conditions before setting up the lift; keep your eyes open for soft spots, presence of water, or places that may have shifted due to thawing.

- To prevent the machine from sinking into the mud or loose soil, use outrigger pads or cribbing to broaden the area over which the lift’s weight is distributed.

- Don’t let the lift get too close to trenches or excavations as the walls of these can get weakened due to spring rains causing sudden collapses.

Protection from Moisture and Electrical Maintenance:

- Check inside and outside the electrical components, wiring, control boxes for moisture or corrosion infiltration that might have accumulated during the wet season transition.

- Make sure that control panel and battery compartment sealing features are not compromised and are working efficiently to keep the rain out and the electrical system free from short circuits.

- Scrape off mud from the chassis and scissor stack every day as the wet soil allows for structural cracks to remain hidden and also moisture trapped against metals lead to rust.

Maintenance of Tires and Traction:

- Have a look at your tires to ensure there are no deep cuts or chunks of rubber missing that might lead to traction being compromised when you’re operating on wet and slippery ground.

- If you have pneumatic tires, keep them at the right pressure as per manufacturer’s instructions because an incorrect pressure can highly influence stability on uneven and muddy ground.

- If the site is really full of sharp pieces hidden beneath the mud, it will pay off to change to foam-filled or solid non-marking rough terrain tires.

Summer: Handling Heat and Dust

The summer period is characterized by long sunshine hours and mostly good weather which makes it the ideal time for doing construction and maintenance work outside. Still, intense heat is very troublesome as far as cooling systems and batteries in an outdoor scissor lift are concerned.

The devices get overheated quite often during summers, which is the prime reason for the machines to break down and cause delay in work at the same time cost the firm extra for repair. On top of that, a dry summer inevitably brings dust which is like a silent assassin for any kind of machinery as very fine, abrasive particles get into the bearings, pivots, and air filters; hence prematurely wear and even breakdown are caused.

In other words, to get through the summer period your main concern has to be cooling and cleaning of the machine. Operators should also constantly monitor the temperatures of engines as well as the levels of various fluids while the maintenance team would have to prepare a thorough cleaning schedule.

An important point in explanation of how heat affects the battery chemistry is when the high temperature is capable of evaporating the electrolytes in lead-acid batteries which is the irreversible damage to them.

Optimizing Cooling System:

- Remove dirt and debris regularly by washing the radiator and oil cooler fins; this will enable better air circulation and lower the risk of engine and hydraulic system overheating.

- Keep on top of filling the radiator with coolant by checking it every day and making sure the mixture is correct; just putting water in is not good as it dilutes the anti-corrosion additives and lowers the boiling point of the mixture.

- Inspect hoses and fittings of the hydraulic system to spot the leaks and wear tear at the earliest which thinned hydraulic fluid has resulted in more leaks from the worn-out seals.

The battery needs special care:

- Due to increased heat leading to a faster evaporation of battery water, check the electrolyte level of batteries more often and only top up with distilled water – but charge the battery first.

- Make sure that battery compartments are sufficiently ventilated so that heat can dissipate and hence thermal runaway and battery casing distortion can be avoided.

- Routinely clean battery terminals to save from corrosion buildup that can increase resistance and cause the battery to generate excessive heat while in use.

Dust and air filtration:

- Perform engine air filter check each day in very dusty working condition and replace it more frequently than what the normal maintenance schedule suggests.

- Apply grease regularly at all pivot points and zerks to first wash away the contaminated old grease and then fresh grease will be a good barrier against abrasive dust particles.

- Wiping the hydraulic cylinder rods clean will help prevent dust from getting through the wiper seal and entering the hydraulic system.

Autumn: Getting Ready for Wind and Falling Leaves

- As a transitional phase, autumn tends to catch operators unprepared quite frequently. The most significant hazard for outdoor scissor lift during this season is wind which is something that all operators have to take into consideration even though the temperatures keep dropping.

- It is not uncommon for gusty days being also in fall season, the load of scissor lift acts like a sail when it is holding the highest position which results in wind speed overcoming safe operating limit by far. What is more, the fallen leaves and other debris make the surface of the ground inaccessible for the operator along with clogging the machine components.

- In fact, it is also the perfect time for the annual winter fleet “makeover”. This is a mistake that comes with a big price if you ignore your equipment until the first frost arrives.

- In autumn, the maintenance that prepares for winter should mainly concentrate on stability and wind-related safety features as well as switching to winter-grade fluids when you are working in a cold climate.

Procedures for Wind Safety:

- Always keep to the manufacturer’s prescribed wind speed limit (usually 28 mph / 12.5 m/s); use a handheld anemometer to accurately measure the wind velocity at the level of the platform, it is not enough that ground level is measured.

- Know and be able to recognize the “wind funnel effect” that takes place between buildings or other types of constructions, it may significantly increase the wind speeds of those specific areas.

- Without engineering approval, you should never go ahead and install banners, large sheets, or cladding on the scissor lift rails as it will increase the load of the wind and there is a probability that the lift might topple over.

Dealing With Debris and General Housekeeping:

- Remove fallen leaves and twigs from chassis and platform on a regular basis; dry organic matter can potentially catch fire if it is left accumulating near hot engine or exhaust.

- Be sure to check that the leaf-covered surface is safe from hazards such as potholes, manhole covers or loose gravel that can cause the lift to be unstable.

- Make sure that rain gutters and machine drains are cleaned and that the leaves are not preventing water flow, as this could cause water to pool and freeze.

Getting Ready for Winter:

- Make sure the battery is able to provide power and can be recharged properly.

- Measure and confirm the freezing point temperature of engine coolant and hydraulic fluid – if the temperature is too low, you will need to drain and replace these fluids before the coldest time of year.

- Check all weather-resistant strips and cabin enclosures (should you have one) to make sure the operator will be shielded from cold winds.

Winter: Fighting the Cold and Slippery Surfaces

Winter is by far the hardest season for machinery in physical terms. Besides difficult starting, an outdoor scissor lift will also experience greatly reduced battery performance and the terrain becoming more unsafe.

The low temperature makes the oil for the engine and the hydraulic fluid very thick, so until the machine has warmed up, it will be slow and less responsive. At 0°F (-18°C) batteries can produce only half of the normal current for cranking and hence you will have lots of non-starts.

Besides, snow and ice can make the place of work like a rink. The operator and the machine are both exposed to the danger of falling, and without proper lubrication the scissor mechanisms freezing might not operate properly.

Working in winter requires a certain calmness; if you simply go straight to full operation with a machine that has not yet been heated you will risk blowing hydraulic seals or breaking brittle components that cannot take the sudden effort.

Cold Weather Machine Starting and Warming Up:

- First, you should let the lift stand idling for a while to allow the hydraulic oil and engine fluids to warm up sufficiently before you operate lift functions because otherwise, the system will get “thermal shock”.

- By blocking heaters or battery blankets, you can save the temperature of your engine and power source during night and comfort your next morning’s engine starting.

- Nowadays, synthetic oils and winter-grade hydraulic fluids are available on the market, which will facilitate a smooth machine operation even after the decrease in temperatures.

Ice and Snow Management:

- Before any work is started, the platform floor, stairs, and handrails should be cleared of snow and ice so the operator can move safely.

- Removing ice and snow from the scissor stack and chassis regularly helps to avoid them getting stuck and prevents the lift from retracting after use (which becomes a transport safety issue).

- Chains or studs can be used on packed snow or ice, just ensure first that the chains match the type of tire and that the surface will not be damaged.

Battery Preservation:

- Electric scissor lifts should be plugged in anytime they are not used; this way the battery will not discharge and freeze, preventing cracks to the case from occurring.

- If you are going not to use a lift for some time, store batteries at room temperature or use a trickle charger to keep them charged.

- Regular cleaning of battery terminals is extremely important as the cold weather may exacerbate the effects of poor connection and cause voltage drop.

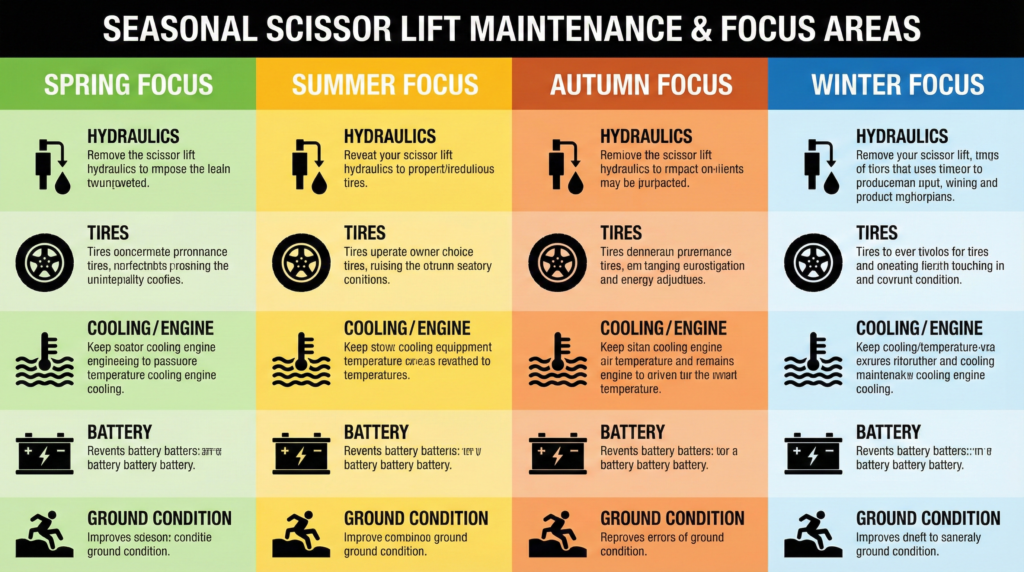

Comparison of Seasonal Maintenance Priorities

In order to help you understand the trend of changing priorities, the following table summarizes those areas which each season demands the most attention to.

| Feature / System | Spring Focus | Summer Focus | Autumn Focus | Winter Focus |

| Hydraulics | Check for water ingress/contamination. | Check for leaks due to thinning fluid. | Inspect hoses for cracking/brittleness. | Use low-viscosity fluid; warm up properly. |

| Tires | Inspect for mud impact & deep cuts. | Check pressure (heat expands air). | Check tread depth for wet traction. | Use chains/studs; check for cracking. |

| Cooling/Engine | Clean radiator after pollen season. | Daily debris cleaning; check coolant. | Clear leaves from intake/exhaust. | Use block heaters; check antifreeze rating. |

| Battery | Clean corrosion from wet conditions. | Water frequently (evaporation risk). | Load test for winter readiness. | Keep fully charged; store in warmth. |

| Ground Condition | Watch for soft mud/sinkholes. | Watch for dry, dusty, loose soil. | Watch for debris hiding hazards. | Watch for black ice and packed snow. |

FAQs: Outdoor Scissor Lift

Do electric scissor lifts work outdoors?

They do, but you have to be aware of the limits. Generally, electric scissor lifts are intended for indoor use on dry, flat slabs; however, a growing number of manufacturers have come up with “outdoor-rated” electric scissor lifts. Still, you must check on the information plate of the machine. Indoor models usually don’t have a wind rating, so use outside is not only illegal but also very dangerous. Make sure to check the rating for water resistance and use on firm paved level ground.

What is the top wind speed allowed for an outdoor scissor lift?

Typically, the maximum wind speed tolerated by an outdoor scissor lift is 28 mph (12.5 m/s). Nonetheless, there can be some variations depending on the height of the model. If the wind exceeds the allowed limit, the platform has to be lowered right away. Always measure with a handheld anemometer at the platform height as wind tends to be stronger up there than at ground level.

How to decide between a rough terrain and a slab scissor lift?

If your site has uneven surfaces, dirt, gravel, or slopes, then you should definitely get a rough terrain scissor lift. They come with features like heavy-duty tires, elevated ground clearance, and sometimes 4WD. Only when you plan to work on firm, level, paved surfaces like concrete or asphalt should you consider a slab scissor lift (usually electric). A major safety violation is using a slab lift on a dirt surface.

Why does my scissor lift drags in the winter?

The reason for scissor lift being slow in the winter is that the cold weather has made the hydraulic fluid thicker. If the fluid is thick, then it is moving slower through the valves and hoses, so the whole system becomes slow and less responsive. To circumvent this issue, you need to warm up the machine by running it idle for 10–15 minutes before you start using it. In the case of very low temperatures, you may also have to put an appropriate winter-grade hydraulic fluid.

Does outdoor scissor lift operation require any special training?

Definitely. On top of the general aerial lift training basics, outdoor operation requires terrain assessment, weather monitoring (wind/rain), and understanding soil stability. Outdoor operators must also be aware of extra hazards such as power lines and ground changes.

How frequently must I grease my scissor lift?

For outdoor lifts that face dust, rain, and mud, greasing of pivot points, steering mechanism, and outriggers should be done weekly or every 50 operating hours. If the environment is extremely dusty or wet (such as summer or spring), then daily greasing may be necessary to get contaminants out of the bearings.

Is it safe to use a scissor lift over a slope?

Generally, scissor lifts come with a very narrow slope limit such as between 1.5 and 3 degrees when in the raised position. Rough terrain scissor lifts are frequently equipped with auto-leveling outriggers that permit them to be set up on much steeper slopes by leveling the chassis before raising the platform (sometimes this can be as steep as 10–15 degrees). Under no circumstances should you drive a scissor lift when you are elevated on a slope, and always check the slope rating specific to your model.

Decision for Seasonal Choice on Outdoor Scissor Lift

The operation of an outdoor scissor lift is not simply about pressing the right buttons. You need to have a thorough awareness of the interaction between the environment and your machine.

You will be safer and more effective if you align your inspection and maintenance activities with the four seasons’ cycle—tackling mud in spring, heat in summer, wind in autumn, and ice in winter. Do keep in mind that the better the machine is kept, the safer it is.

To find more professional knowledge as well as to get tips on safety and more detailed tutorials on aerial work platforms, check out https://scissorlifts.org/ and let your industry expertise soar.

Outdoor Scissor Lift