Innovative Uses of Industrial Scissor Lift Tables in Manufacturing

Different Usage of Industrial Scissor Lift Tables in Manufacturing Industry

Today, most consumers want the fastest and cheapest products so manufacturing is always under pressure to be more efficient. However, in pursuit of speed, efficiency usually forgets one of the most versatile tools on the factory floor: Industrial Scissor Lift Tables.

People still think of these heavy-duty devices only as a means of getting things off the floor and up to a certain height. However, today, they are increasingly regarded as a crucial element of smart manufacturing systems that enable human workers and robots to work together smoothly.

In their shift towards Lean Manufacturing and Industry 4.0, many industries have discovered how the once ‘simple’ scissor lift table can be used to overcome complex logistics problems, solve MSD issues, and optimize factory floor layouts. Keeping a constant, ergonomic working height, these tables allow materials to always be kept in the operator’s “Golden Zone” – the area between the waist and shoulders where safety is highest and efficiency at its peak regarding manual handling.

Moreover, fitted with state-of-the-art hydraulics, pneumatics, and electronic control systems, they have become the unfaltering partner of production lines, demonstrating that revolution is often about re-inventing the basic tools in the trade.

Optimizing Ergonomics and Reducing Workplace Injury

The impact of Industrial Scissor Lift Tables on Ergonomics and Injury Prevention at Work: An Overview.

The primary benefit and greatest contribution of Industrial Scissor Lift Tables to ergonomics is actually the fact that it can keep the material at the work height and therefore, the worker does not need to adopt awkward postures. In a traditional manufacturing cell, it is common for workers to resort to bending, stretching, twisting, etc. to get hold of the heavy components, which naturally leads to fatigue and injuries in the long run.

What the new generation of industrial scissor lift tables does is to automatically adjust and “lock” the height of the work-piece when adding or removing layers. This is very important in palletizing and depalletizing work as the load height is constantly changing. Along with less injuries among the workforce, there is the other side of the coin which is the rise in employee morale and productivity.

What really sets auto-leveling tables apart is that they are “set-it-and-forget-it” type of solutions that adjust the height of the platform using mechanism based on airbags or springs without the constant manual input.”

- Prevention of Musculoskeletal Disorders (MSDs): Keep heavy lifting and handling within the body’s power zone.

- Auto-Leveling Features: Platform height is automatically adjusted when load is added or taken away, no operator intervention is needed.

- Reduction of Fatigue: Minimizes the energy expenditure of labor, thereby allowing workers to sustain higher levels of concentration and accuracy for the entire shift.

Integration with Automated Conveyor Systems

Automation-Friendly Transfer and Loading Stations Featuring Integration of Industrial Scissor Lift Tables.

An extremely innovative creative scissor lift application is embedding Industrial Scissor Lift Tables into automated conveyor systems. They don’t have to be separate units on an island any more, but rather transfer points with the capability to lift, lower, or tilt can be used in any factory at the same time that connects different levels of the conveyor.

This is a great solution when your manufacturing plant has multiple floors, and you use gravity-fed conveyors to get the product to a lower level, but then you have to reset the conveyor to a higher level or a product that has to be lifted to the robot’s hand for assembly.

With the addition of powered rollers or ball transfer units to the lift table platform, manufacturers have a pipeline without any interruption of human handling giving through the whole chain of the process.

- Vertical Transfer Units: Elevator for pallets between stacked conveyor levels, thus saving the industrial floor space.

- Robotic Interface: Precisely places the products for robotic welding or assembly with a robot arm, thereby ensuring high repeatability.

- Seamless Material Flow: Roller tops make it possible for products to be passed onto the lift without stopping the production line momentum.

Enhancing Assembly Flexibility with Mobile Scissor Lifts

Modular manufacturing has led to the widespread use of mobile Industrial Scissor Lift Tables, which are quite different from the traditional, fixed units. According to manufacturing professionals, these devices may be likened to powered pallet trucks with hydraulic lifts capable of handling heavy loads.

In a “work cell” manufacturing environment, since a product is transported through different specialized workstations instead of following a linear progression, the mobile lift table serves the variableheight workbench function of traveling with the product. Recently, improvements to battery packs have resulted in weight reduction and longer operation times, which facilitate the production without interruption.

Changes in factory layouts can be accomplished quickly without any costly infrastructural changes such as digging pits or bolting equipment down, all this being made possible by these user-friendly mobile lift tables.

- Dynamic Work cells: The product being worked on and the workstation can move together thus reducing static lifting points in the production area.

- Rapid Reconfiguration: Supports rapid changes in factory layout required for high-mix, low-volume production patterns, the most common nowadays.

- Battery-Powered Independence: utilizes high-capacity lithium or AGM batteries to provide consistent lifting power without trailing cables.

Turning and Tilting Hoisting Functions

In the context of how Industrial Scissor Lift Table manipulates the object, not only the lifting function but also the tilting and rotating are innovated. Operators can turn the heavy load 360 degrees using table turners or they can tilt it up to 90 degrees by using tilt tables.

In case of container filling or assembling a complex set from the bottom, these devices provide the help. Then work that you had to do by walking around the pallet or leaning over a bin (and your back took the brunt) is now just a matter of the table bringing the work close to you.

Auto makers have found use in chassis turning to enable their welders to-do down hand welding (the strongest and also the most efficient weld) as opposed to overhead welding. Most significantly, the speed of operation and finish quality are greatly improved thanks to the manipulator that can be positioned to the desired angle.

- Bin Positioning: turning wire baskets or containers toward the operator to facilitate /parts retrieving/ without unnecessary bending.

- 360-Degree Access: Workers can stay in one position and access all sides of the pallet or assembly if the integrated turntables are used.

- Process Quality Improvement: The workpiece is put into the most suitable position for the tasks such as welding, painting, or inspection.

Flush-to-Floor Scissor Lifts and Entry-Level Solutions

With the help of pit-mounted Industrial Scissor Lift Tables, some manufacturers can go on using their existing floor space without having to worry about tripping over ramps, which of course are also dangerous and take up space as well.

These tables which are known as Zero-Entry or Low Profile lift tables are really the innovation as they physically can be hardly distinguished from the floor, however, they can be lowered even to less than an inch in height thus a standard pallet jack is allowed to roll on to the platform without a pit digging.

The feature of these ultra-low tables to be used in rented facilities as well as in upper floors, where it is impossible to dig a concrete pit, is the main point of this innovation. By following their design approach, the scissors are of a different geometry and the power units have been moved outside, hence they can still handle very heavy loads whilst a single human operator with a manual pallet jack would suffice. There is thus no longer a bottleneck caused by the need to wait for a forklift.

- No Infrastructure Modification: These kinds of “Zero-Low” designs do not require any pit excavation, so they are very best choice for spaces that are being leased or for mezzanines.

- Forklift Independence: Manual pallet jacks can be used for loading the table thus making the forklifts available for the longer-distance transport tasks.

- Tripping Hazard Reduction: With the elimination of ramps that are long and steep it becomes possible to have/floor space is reduced and at the same time safety hazards are diminished.

Comparing Industrial Scissor Lift Table Power Systems

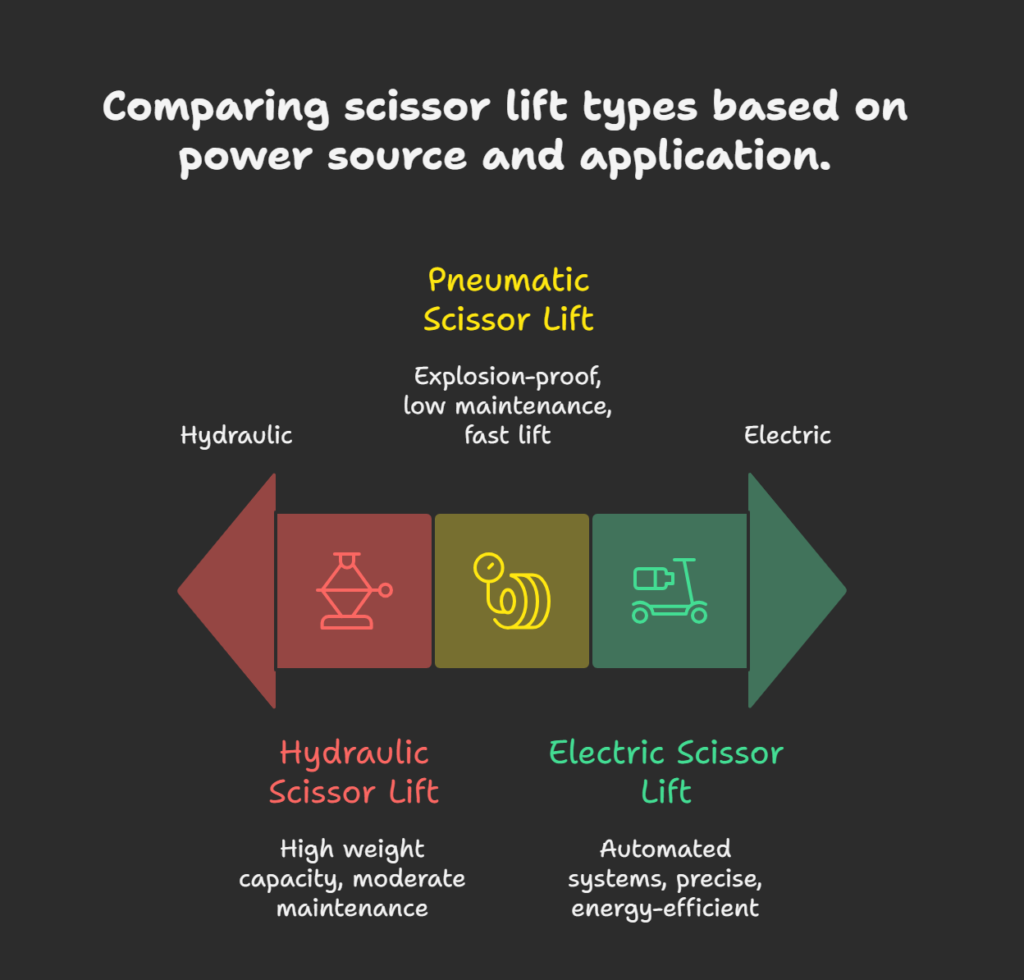

During the procurement of lifting table, apart from considering the technical specifications and features, one of the most important things is to understand the power source behind the units. It is only once a detailed comparison of the pros and cons of different operating systems of these tables is conducted that the right choice can be made.

Table: Choose The Best Industrial Scissor Lift Tables Type

| Feature | Hydraulic Scissor Lift | Pneumatic (Air) Scissor Lift | Electric (Screw/Belt) Lift |

| Primary Power Source | Pressurized hydraulic fluid (Oil) | Compressed air (Airbags) | Electric motor & spindle |

| Best Application | Heavy-duty lifting, high weight capacity | Clean environments, explosion-proof areas | Precision positioning, automated systems |

| Maintenance Needs | Moderate (Check for leaks, oil changes) | Low (No fluid, fewer moving parts) | Low to Moderate (Greasing, belt checks) |

| Lift Speed | Steady and controlled | Fast and “bouncy” (compressible) | Very precise and consistent |

| Environmental Impact | Risk of oil leaks (contamination) | Clean (ideal for food/pharma) | Clean and energy-efficient |

| Cost Profile | Economical for high capacity | Higher initial cost, lower maintenance | Higher cost for precision control |

FAQs – Industrial Scissor Lift Tables

How does an Industrial Scissor Lift Tables function and how does it improve the efficiency of a manufacturing line?

An Industrial Scissor Lift Tables is a platform typically used in material handling that has a built-in ‘scissor’-shaped lifting mechanism that helps to raise and lower heavy loads and materials to the desired height. The working efficiency can be improved by having the work set at the correct ergonomic level, minimizing the time and effort that the workers have to spend on contacting the floor or getting up and down, as well as the ready integration of these tables into a fully automated production line.”

What are the main differences between Hydraulic and Pneumatic Scissor Lift Tables?

The main difference is the actuation method employed. Whereas hydraulic lift tables utilize pressurized liquid and cylinders to generate tremendous lifting force thereby making them suitable for lifting heavy loads (2,000+ lbs), pneumatic lift tables rely on heavy-duty airbags filled with compressed air instead; these are cleaner, faster, and require less maintenance but cannot handle as much load as the hydraulics do.

How do Scissor Lift Tables help in preventing Injuries at Work?

They are pieces of equipment with built-in features that help avoid musculoskeletal and other types of injuries related to incorrect manual lifting techniques and bad posture. First, by keeping the load within the “Golden Zone” (between the waist and shoulder height), the chances for injuries resulting from repetitive loads on the back are minimized substantially. Second, by providing carriers capable of adjusting to the user’s body, the risk of physical incapacitation is almost nonexistent.

Could Industrial Scissor Lift Tables be Customized to Meet the Specifications of Assembly Line?

Absolutely, it is a very popular practice to tailor the table to achieving the best fit with the operational standards on the assembly line. For example, manufacturers have the option to add turntables, tilt tops, conveyor rollers, or ball transfer decks. Moreover, the same tables can also be equipped with safety bellows, automated height stops via limit switches, and different-sized platforms that can be used with unique product dimensions

How Much Weight Can a Typical Manufacturing Scissor Lift Table Handle?

The average model for an industrial scissor lift table has a capacity range of 1,000 lbs to 10,000 lbs. That said, high-performance or custom-made heavy-duty scissor lifts can go up to 50,000 lbs or more, particularly when they are intended for sectors such as aerospace or heavy machinery manufacturing which have strict requirements for material handling equipment in terms of load capacity.

Is Pit Installation Necessary for Scissor Lift Tables?

In the case of a typical standard scissor table lift whose collapsed height ranges from 8-10 inches, it may be practically impossible to do floor-level loading without the use of a pit. Then, in turn, the low-profile or zero-entry lift tables that have been built precisely to be nearly level with the floor and loaded with a pallet jack have solved this problem. I.e., it is now easier to install the units without having to dig a pit.

What Are the Safety Features for the Operation of Scissor Lift Tables?

Yes, it is obligatory to follow the safety guidelines in this case as well. The standards that would apply are ANSI MH29.1 (Industrial Scissor Lifts). Usually, the key safety features include the following: toe guards, which are there to prevent foot crushing; velocity fuses, which are devices that stop the lift in case of a hose burst; maintenance chocks, are used to mechanically support the table during maintenance.

Industrial Scissor Lift Tables – Wise Choice Summary:

The evolution of Industrial Scissor Lift Tables reflects the broader transformation of the manufacturing sector. No longer just simple lifting devices, today manufacturing scissor lifts are a safe, ergonomic, and highly efficient production line technology.

This is made clearer by the fact that these valuable aids through their various features significantly reduce manufacturing risks and simultaneously increase workers’ productivity. Besides that, various types of these tables in the factory are incorporated with each other’s functionality like low-profile tables without needing a forklift, mobile units with flexible workspaces, and more.

Facility managers and engineers who are buying new work equipment are not simply purchasing a product but are making a wise investment decision in a sustainable, ergonomic, and future-proof manufacturing process.