How Industry 4.0 Is Transforming Scissor Lift Technology and Safety

Scissor lifts are the major contributors in construction, maintenance, event production, and industrial applications, where workers and equipment need to be safely elevated because of the advancements in scissor lift technology. After the emergence of Industry 4.0 – the fourth industrial revolution that is characterized by connected smart technologies – the evolution of scissor lift technology and safety has been a transformational one.

The transformation extends to new operational efficiency, safety at work, environmental friendliness, and overall productivity, which changes to a great extent the usual way of designing, using, and maintaining these machines.

Industry 4.0 and Smart Scissor Lift Integration

Industry 4.0 is an integration of advanced technologies such as Internet of Things (IoT), sensors, telematics, automation, and data analytics into old machines. For instance, in scissor lifts, this denotes the presence of smart controls and real-time connectivity that are going to be standard features.

- Sensors that are implanted in scissor lifts deliver the continuous monitoring of main parameters such as platform height, load weight, tilt angle, and machine condition.

- Telematic control systems provide the possibility of remote tracking and diagnostics, thus, fleet managers and service teams can have a look at the lift location, usage, and maintenance needs anytime and anywhere.

- Automation features embrace self-diagnostic checks and obstacle detection technologies through which the behavior of the lift can be adjusted automatically for safety and efficiency without the need for human intervention.

Such innovations are doing the job of maximization of the time without machine failures by looking into problems in advance, thus, operator confidence is on the rise due to instant feedback and alerts.

Enhanced Safety Features Powered by Industry 4.0

Height working has always been a source of concern, however, the second generation scissor lift technology Industry 4.0 that powers the advancement, is a major contributor to safety improvement of the operators.

- Pothole Protection Systems: At present, scissor lifts of the best quality are equipped with the functionality of automatically lowering ground clearance when elevated so that tragedies due to uneven terrain or potholes are prevented.

- Load Sensing and Overload Protection: In case the platform is overloaded, force or pressure-based sensors will realize that and will ensure that the load on the platform is removed thus, the risk of tipping is decreased significantly.

- Variable Tilt Technology: Accurate sensors can ascertain the gradient, height, and load and hence allow operations on slopes measuring up to three degrees without risk.

- Drive and Lift Interlocks: If safety interlocks detect dangerous situations, they will cease lift operations thus, keeping the environment safe for workers.

- Audible and Visual Alerts: Movement or emergency situations are the moments when operators and surrounding workers receive warnings through sound and light signals.

- Manual Lowering Systems: In the event of a power failure or an emergency situation, the accompanying safety measures include the presence of manual fallback mechanisms to handle it in a safe manner.

Besides that, telematics provide an array of benefits such as easy access to safety status, generation of usage reports, and prevention of unauthorized operation of the machine, thus, accidents arising from human errors being reduced in such a way.

Eco-Friendly and Efficient Power Solutions

Another factor that Industry 4.0 has been influencing is the innovation leading to sustainability and power being the main concerns of scissor lifts.

Electric and hybrid scissor lifts are becoming more and more popular as they are free of emissions and quiet in operation, which makes them suitable for indoor places and noise-sensitive environments.

Innovative battery management systems not only extend the work time on battery power but also give the operator a real-time battery status which is a great help in ensuring continuous work.

The move towards going green is in line with the worldwide goal of carbon reduction, which is pushing manufacturers to come up with eco-friendlier lift technologies, for example, investigating the possibility of using hydrogen as fuel.

Versatility and Adaptability with Smart Controls

The advances of Industry 4.0 scissor lift technology have widened the use of scissor lifts to different places and conditions:

- With compact designs, the lifts can go through very narrow spaces such as warehouses and residential areas.

- By the use of four-wheel drive, rough terrain tires, and extendable stabilizers, the all-terrain scissor lifts can operate safely on uneven outdoor surfaces and slopes with up to 40% gradient, thus, there is no limit to where they can be used.

- By means of smart controls, the performance of the machine can be tailored to meet the requirements of the jobsite thus, the operator’s comfort will be ensured as well through smoother stops and accurate control of movement.

Through the connection of systems remote diagnostics and software updates can always be done in the equipment, thus, the equipment will not only be up-to-date, but it will also be adapted to the conditions of the field.

Industry 4.0 Improves Maintenance and Downtime Reduction

The utilization of smart service diagnostic tools will bring a very great reduction of the maintenance time to a few minutes:

- Real-time fault codes and system alerts provide a quick way of issue pinpointing.

- Usage-data-driven predictive maintenance has the ability to locate component failures beforehand.

- Technicians can efficiently work out problems with the aid of smartphone connectivity for remote diagnostics, thus, the times when machines have to remain idle are kept to a minimum.

- Maintenance supported by data will be a long time solution for lifts with safe operations and it will, in the long run, contribute to a cut in overall operational costs.

Market Growth and Impact of Industry 4.0 in Scissor Lift Technology

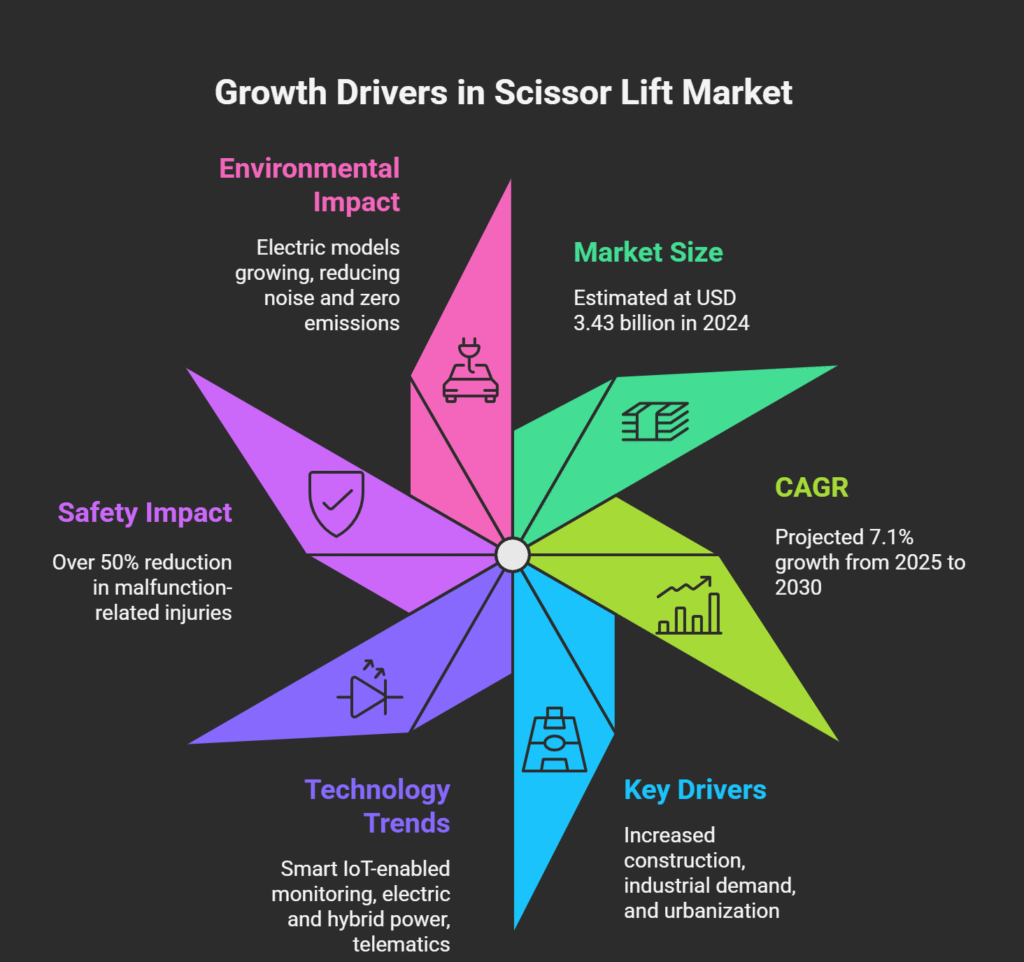

The global scissor lift market is set to continuously expand with Industry 4.0 technologies being the main factors contributing to this growth:

| Aspect | Details |

| Market Size | Estimated at USD 3.43 billion in 2024 |

| CAGR | Projected 7.1% growth from 2025 to 2030 |

| Key Drivers | Increased construction, industrial demand, and urbanization |

| Technology Trends | Smart IoT-enabled monitoring, electric and hybrid power, telematics |

| Safety Impact | Over 50% reduction in malfunction-related injuries with ANSI-compliant smart lifts |

| Environmental Impact | Electric models growing, reducing noise and zero emissions |

This growth of the market is a reflection of the great extent to which the automated, safe, and eco-friendly scissor lifts are being adopted by industries such as construction, warehousing, manufacturing, and event production at the same time.

Summary of Key Industry 4.0 Features Transforming with Scissor Lift Technology

- Presence of IoT sensors and use of telematics for getting data and controlling machines from distance

- State of the art safety provisions like pothole protection, attentiveness to tilt, overload prevention

- Reduction of operational halt through automated system checks and predictive maintenance

- Electric/hybrid propulsion with smart battery management

- Lift models empowered by intelligent command units turning small and rough terrain accessible

- Connection with management of vehicle fleets and safety environments at work

At the core these innovations are pumped up with technologies that bring safer working environments, improved operational efficiencies, and reduced environmental footprints.

To Sum Up – Future of Scissor Lift Technology

Industry 4.0 scissor lift technology means merging IoT, automation, and green energy solutions to completely change the scenery of safety, efficiency, and eco-friendliness. Those in business who are ready to take in these developments will see a decrease in the number of accidents and operational costs, as well as an increase in productivity. For detailed expert insights and ongoing updates on scissor lift innovations, kindly visit scissorlifts.org

Frequently Asked Questions (FAQs) – Scissor Lift Technology

What is Industry 4.0 and how does it relate to scissor lifts?

Industry 4.0 means a set of intelligent and connected technologies integrated into different sectors. Scissor lifts have become more efficient and safer due to improved sensor technology, telematics, and automation in line with Industry 4.0.

Are electric scissor lifts part of the Industry 4.0 trend?

The answer is yes. Electric and hybrid scissor lifts come with smart battery management and zero-emission operation, which makes them conforming to the Industry 4.0 focus on sustainability and efficient power use.

How do smart safety features work on modern scissor lift technology?

Smart features like load sensing, pothole protection, tilt sensors, and interlocks utilize real-time data to stop operations that may be unsafe and inform operators thus, accident risks are minimized considerably.

Can Industry 4.0 scissor lift technology reduce maintenance costs?

Certainly. Predictive maintenance, remote diagnostics, and real-time fault alerts facilitate the fixing of issues before breakdowns thus, downtimes and repair costs are reduced.

What advantages do telematics provide in managing scissor lifts?

Efficient asset management through remote tracking, usage monitoring, unauthorized access prevention, and data-driven maintenance are some of the benefits telematics brings to fleet operation and safety.

Are industry safety standards changing with new scissor lift technology’s?

Indeed, standards like ANSI A92.6 have now added criteria for automated safety features and diagnostics which are met by smart scissor lifts to result in decreased workplace injuries.

How does Industry 4.0 improve scissor lift versatility?

Smart controls make it possible to adjust performance according to the needs of the jobsite thus, facilitating the use of the lifts in small spaces indoors or in the rugged terrains outdoors with safety and efficiency.