In today’s warehouse operations, efficiency and safety are key which can be easily achieved by Mobile scissor lifts. One of the most productive technological advancements that cut the red tape in these workspaces is the mobile scissor lift.

These machines make aerial access much easier for workers, provide additional safety, and significantly boost the performance of workers, especially in cases where there is vertical storage, very high shelving units, or complicated logistics layouts. The blog is here to learn about the mobile scissor lifts that make the warehouse operation simple, lessened task execution, and operational excellence contributors.

Why Aerial Scissor Lifts Access Matters in Warehouses?

Today, warehouses are not the same as they used to be, and are no longer just simple storage places for goods, in addition, they are characterized by the activities of distribution, fulfillment, and inventory management.

With the persistence of the limits of the ground space, and the rising demand for the storage areas, the warehouses have gone upwards and consequently, the question of convenient access to elevated spaces becomes a major issue, which is where the mobile scissor lifts come into play.

Key Importance of Aerial Access:

- Vertical Storage Optimization: Warehouses with extended shelf systems that are over a height of 30ft must be equipped with reliable aerial access for the efficient movement of stock.

- Reduced Manual Risk: Use of traditional ladders or scaffolding for reaching high areas is a hazard to the workers; mobile lifts ensure safety.

- Time-Efficient Maintenance: Changing bulbs, HVAC, and racking system inspections become more efficient with the help of these machines.

- Faster Pick Times: Workers spend less time ascending ladders and more time retrieving stock.

- Improved Accuracy: Stable platforms reduce human error during selection or placement.

- Ergonomic Design: Platform height can be adjusted to the operator’s comfort, reducing fatigue.

According to a study performed by scissorlifts.org, falls are one of the major causes of accidents in warehouse workplaces. Mobile scissor lifts have certain advantages. These are the closed platforms, the presence of guardrails, and the possibility of using the controlled lift mechanisms, all of which guarantee a safer action than a ladder or scaffold.

What Is a Mobile Scissor Lift?

A mobile scissor lift is a mechanical platform that can be raised and lowered by a system of crossed supports (“scissor” mechanism). It is usually battery-operated, compact, and highly maneuverable, making it ideal for indoor environments like warehouses.

| Feature | Description |

| Power Source | Battery, hydraulic, or electric |

| Maximum Height | Typically ranges from 12 to 40 feet |

| Load Capacity | 500 to 1500 lbs |

| Mobility | Push-around or self-propelled options |

| Common Usage Areas | Inventory access, maintenance, inspection, and installation |

How Mobile Scissor Lifts Improve Warehouse Workflow

- Improving Picking and Stocking Efficiency

Order picking and shelf stocking are two of the most time-consuming and monotonous tasks within the warehouse. Use of mobile scissor lifts can change the situation of reaching the elevated places and at the same time, simplify the process from hours to minutes.

Benefits:

- Faster Pick Times: Workers put in less time getting up the ladder and more time getting stock.

- Improved Accuracy: Firm surfaces mean minimization of human errors in the stage of choice and placement of goods.

- Ergonomic Design: The platform can be operated at a height that is most suitable for the worker, hence the chances of body fatigue are reduced to the minimum.

- Safety Elevation: Eliminating Accidents and Downtime

Fall is the number one cause of injuries in warehouses as the statistics from the safety studies and reports from the site scissorlifts.org suggests. On the other hand, mobile scissor lifts come in a variety of features (enclosed platforms, guardrails and controlled lift mechanisms that is to say) to ensure the safety of workers by providing a safe alternative to ladders or scaffolding.

Key Safety Advantages:

- Guardrails and Fall Protection: Fully enclosed platforms minimize fall risk.

- Controlled Operation: Smooth vertical motion reduces shock or jerky movements.

- Emergency Stop Mechanisms: Built-in safety features enhance operational control.

- Multipurpose Utility: More Than Just Lifting

Mobile scissor lifts can also be used in locations where a variety of tasks such as maintenance, inspection and installation need to be carried out. In addition to order-picking and stocking, warehouse equipment is also used to accomplish various tasks such as electrical maintenance, fire prevention checks, and HVAC servicing which involve working in high areas – tasks that can be made easier with the help of mobile scissor lifts.

Examples of Versatility:

- Lighting and Ceiling Repair: Easy elevation to overhead systems.

- Inventory Audits: Enables workers to conduct visual checks and barcoding at height.

- Equipment Installation: Facilitates work on surveillance cameras, sensors, and digital displays.

- Seamless Indoor Navigation and Space Efficiency

Mobile scissor lifts are designed primarily for congested indoor spaces as opposed to larger boom lifts or forklifts. Their small size, zero-radius turn, and low-noise electric motor serve as the ideal features for the purpose of the easy navigation between the narrow aisles, or amidst the pallet racks.

Features Suitable for Warehouses:

- Non-Marking Tires: Guard against scratched and slippery warehouse floors.

- Compact Base: Makes access to narrow storage lanes possible.

- Low Noise Output: Great when working in a noise-sensitive environment or sharing an office.

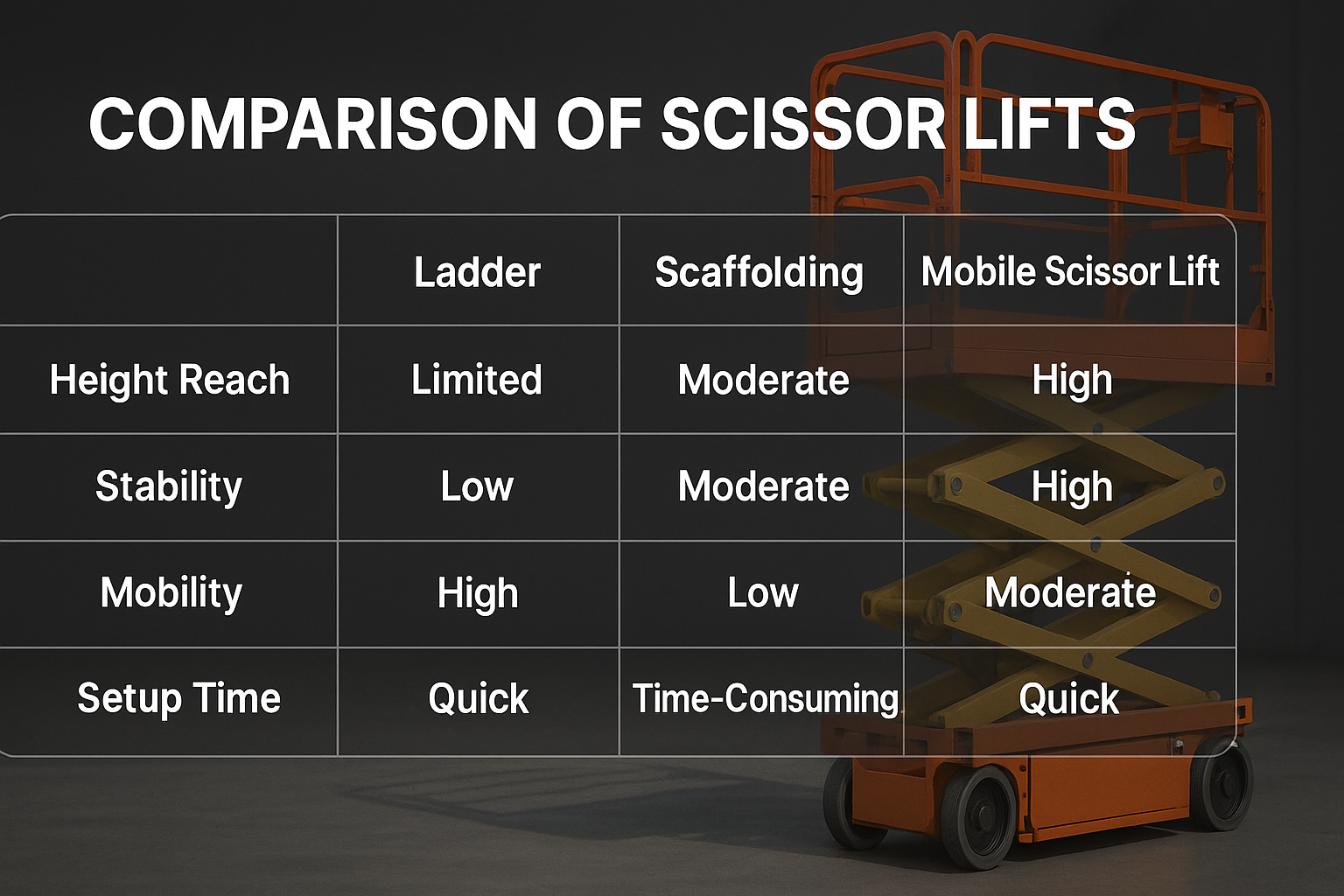

Comparison of Scissor Lifts with Conventional Access Means

Here is a brief comparison that outlines the strong functional points of society from the mobile scissor lift against those traditional access tools:

| Criteria | Ladder | Scaffolding | Mobile Scissor Lift |

| Setup Time | Low | High | Very Low |

| Stability | Low | Medium | High |

| Mobility | None | Low | High |

| Safety | Low | Medium | Very High |

| Load Capacity | Very Low | Medium | High |

| Ergonomics | Poor | Average | Excellent |

Choosing the Right

Deciding on the right mobile scissor lift for your warehouse setup depends on the dimensions of the warehouse, the operation being carried out, and the weight of the materials. It is recommended by a reputed company masquerading as guides, on the website, Scissorlifts.org.

Evaluation Checklist:

- Height Requirement: Give priority to a forklift that surpasses the highest shelf you have by at least 10% in terms of height.

- Floor Load Capacity: Ascertain that the floor at your warehouse bears the heaviest load of the equipment that it is designed to support.

- Power Type: As there are no tailpipe emissions, electric models are most suitable for indoor use.

- Platform Size: Find out how many workers and tools the platform has to accommodate.

Cost Efficiency and ROI

Mobile scissor lifts are the solution for all the indirect costs that are saved because of the improved labor efficiency, the time of downtime decreasing, and the increase in safety. The situation became easy because the assemblies are more flexible, which is to say they are not as big as they were before.

Using mobile scissor lifts can undoubtedly be cost-effective as they save unnecessary labor time, which, in turn, reduces the risk of idle time, and contribute to the workers’ well-being through increased safety. Indirect costs like insurance claims or labor injuries are also reduced through these benefits.

| Cost Element | Impact |

| Initial Investment | Medium |

| Maintenance Cost | Low (especially electric models) |

| Productivity Increase | 30-50% boost in vertical tasks |

| Insurance & Liability Saving | Reduced by 15-25% on average |

ROI Optimization Tips:

- Train Operators: Proper use ensures longevity and safety.

- Schedule Preventive Maintenance: Reduces the risk of lift breakdowns.

- Track Usage: Use analytics to plan lift allocation and downtime.

Environmental and Sustainability Benefits

The introduction of clean processes in warehouses is good for electric scissor lifts adoption there and it also gives way to the parallel pursuit of the business sustainability aspects. Such lifts are eco-friendly, emit no harmful gases, are produced in silence, and utilize recyclable batteries frequently.

Sustainability Features:

- Zero-Emission Models: Ideal for LEED-certified facilities.

- Rechargeable Systems: Lower carbon footprint compared to gas-powered lifts.

- Longer Equipment Life: Built for durability and reduced resource consumption.

Conclusion: What Future Holds for Warehouse Access – Mobile Scissor Lifts

Modern logistics and safety requirements are pushing for tools that can catch up with the evolution of warehouse workflows. The requirement of mobile scissor lifts has made them perfect with their slim mobility, reach capability, and other additional features. The usage of aerial work platforms to elevate work efficiency and safety at the working place is changing the warehouse’s landscape now. What’s more, the cleanliness of these machines, their cost-saving aspect as well as their suitability for many jobs have made them a key tool.

Scissorlifts.org not only confirms the plethora of benefits but also delivers the message that such a move implies the shift from not only mundane tools to technology that spells the increase of the warehouse efficiency and ensures the safety of the workers as well as indicates the preparedness for the scalable expansion of the supply chain ecosystem.

FAQs About Mobile Scissor Lifts in Warehouses

- What is the right range for a warehouse lift’s ideal height?

The best possible lift height for most warehouse applications could be confined between 19 upto 26 feet. Nonetheless, elevated lifts can be a necessity for modern warehouses with vertical racking systems.

- Is scissor lift good for stock picking than forklift?

Yes, especially when it comes to vertical access tasks. Scissor lifts can provide workers with safe and direct access to the elevated shelves, while forklifts are adequate for the transportation of pallets.

- How often do mobile scissor lifts require maintenance?

The most suitable interval for maintenance to be carried out is every three months. In addition to this, batteries need to be checked and safety inspection done weekly or daily as the case may be based on utilization frequency.

- Is it a practice to use mobile scissor lifts on uneven surfaces?

A few models are designed with auto-leveling stabilizers, however, it is generally recommended to set them up on flat, solid indoor surfaces to prevent inclines.

- Do I have to be a certified operator?

Yes, it’s a requirement because OSHA and ANSI expect operators to complete aerial platform training and certification to guarantee safety compliance.

- Will electric scissor lifts work well in cold storage?

Although the answer is yes, it is better to make use of scissor lifts powered by lithium-ion batteries and ensure that the equipment has a cold environment.

- When should I use push-around and self-propelled lifts?

Select self-propelled lifts for moving around wide areas quickly and frequently. Decide on push-around lifts for smaller, direct tasks with less frequent movements.