Efficiency and safety are top priorities in the construction industry. Whether you are working on a high-rise or managing renovations, you will need dependable vertical access solutions to complete the job. Scissor lifts are versatile machines that have become indispensable on construction sites due to their ability to safely elevate workers and materials. But which scissor lift is best for your project? In this comprehensive guide, we will look at the 5 Types of Scissor Lifts and their specific applications in construction.

What Is a Scissor Lift?

A scissor lift is a type of aerial work platform that provides vertical access by raising a spacious platform. Unlike boom lifts, which can extend horizontally, scissor lifts only move up and down, making them perfect for tasks that require stable and straightforward elevation. With various types available, scissor lifts can be tailored to different terrains, height requirements, and load capacities.

Why Vertical Access Solutions Matter in Construction

Efficient vertical access is crucial for maintaining workflow and ensuring worker safety on construction sites. From installing ceiling panels to painting exterior walls, scissor lifts offer a stable and secure means of reaching elevated work areas. They reduce the risk of falls and provide a solid base for completing tasks, making them an invaluable asset in any construction project.

Types of Scissor Lifts

Let’s take a closer look at the five main types of scissor lifts and their specific uses in construction:

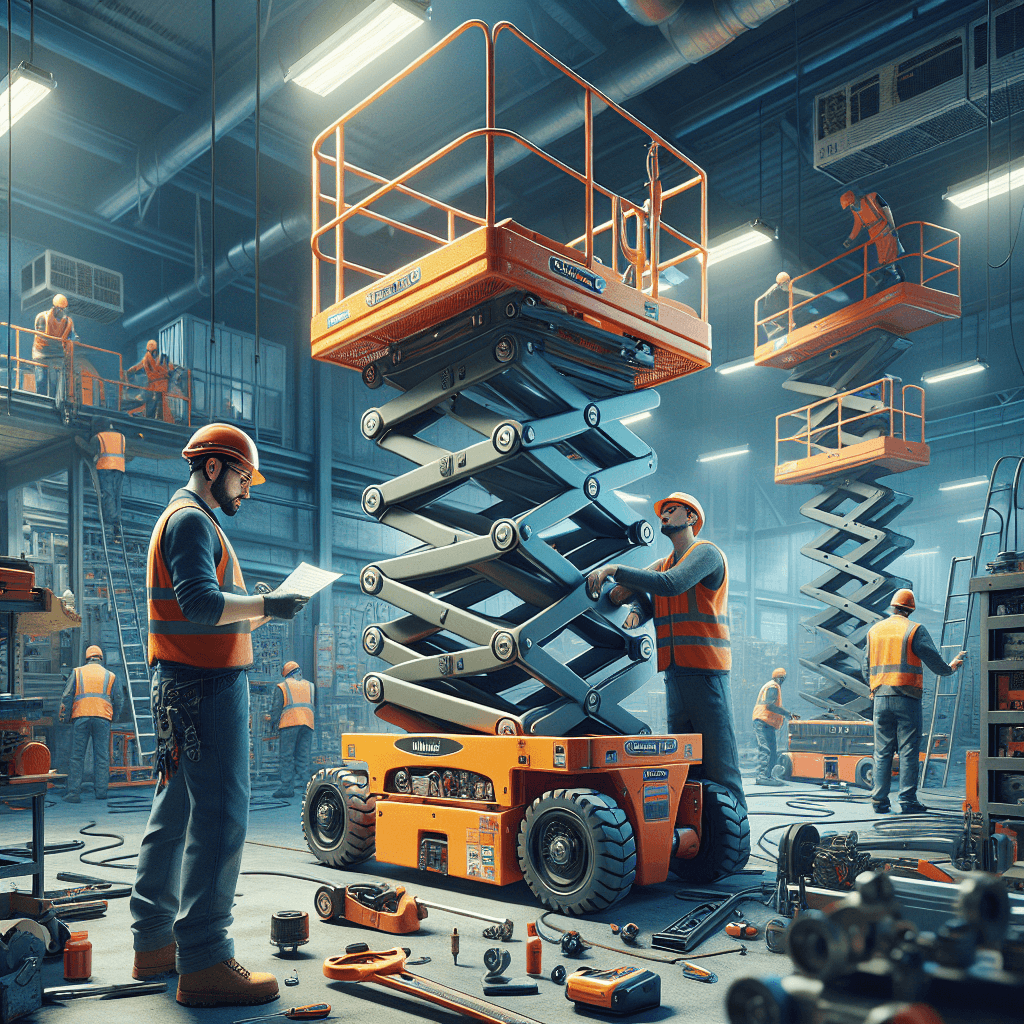

Hydraulic Scissor Lifts

Hydraulic systems that are either hand-operated or engine-driven hydraulic scissor lifts. The changing pressure of the hydraulic oil in the machine helps to operate the lift and move the platform up and down. Since a hydraulic scissor lift is relatively easy to operate, users aren’t required to undergo much training, making it a simple option when you have lifting needs.

However, it’s important to note that oil becomes more viscous in lower temperatures, which can result in slower operation during colder weather. Although this issue has been addressed in newer models, hydraulic scissor lifts are generally best suited for projects where speed and horsepower are not top priorities, allowing for efficient and safe elevation in a controlled manner.

Key Features

Hydraulic scissor lifts utilize hydraulic systems to raise and lower the platform. They are known for their robustness and reliability. These lifts operate using either hand-powered or engine-driven hydraulic systems.

Pros

- Strong lifting capabilities due to hydraulic pressure.

- Durable and long-lasting, built to withstand harsh environments.

- Simple maintenance with fewer electrical components.

Cons

- Slower operation speed compared to electric lifts.

- Potential for hydraulic fluid leaks, requiring regular maintenance.

Optimal Use Cases

Hydraulic scissor lifts are ideal for heavy-duty tasks where durability and lifting strength are crucial. They excel in environments such as construction sites with uneven terrain or industrial settings where robust equipment is needed.

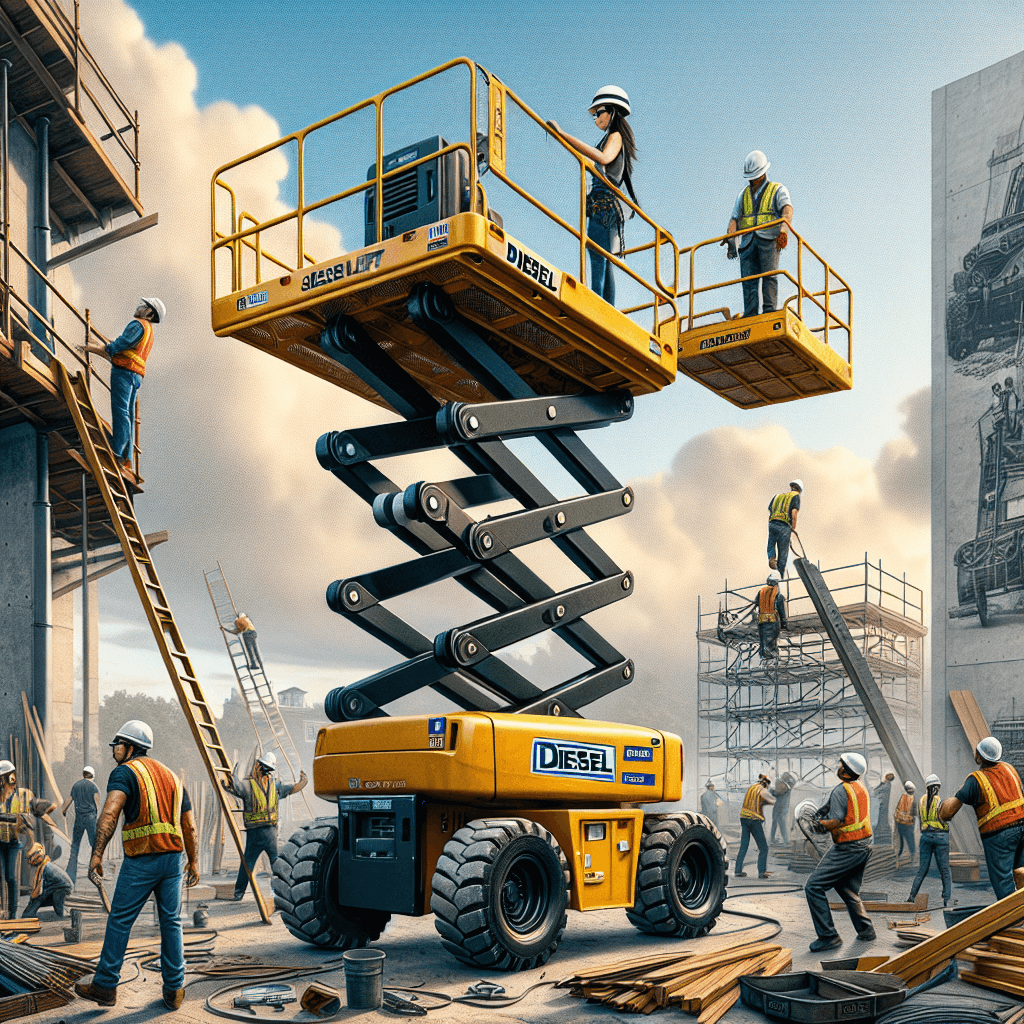

Diesel Scissor Lifts

Diesel scissor lifts are among the most commonly used lifts on construction sites. Their signature cross-braced system allows them to reach a height of 30 feet, with advanced models extending as high as 60 feet. Since diesel fuel powers these lifts, they are noisy and emit fumes into the environment, making them best suited for outdoor construction sites or areas where adequate ventilation is available and noise can dissipate.

Their hefty design also provides them with a larger aerial platform, allowing for more room to accommodate workers and materials. This combination of reach and platform space makes diesel scissor lifts an excellent choice for heavy-duty tasks, particularly in rugged terrain.

Optimal Use Cases

Ideal for large-scale outdoor construction projects, diesel scissor lifts are particularly useful in environments that demand tough machinery capable of reaching considerable heights while providing ample working space for teams.

Key Features

Diesel engines power diesel scissor lifts, making them suitable for outdoor use. They offer substantial power and can reach impressive heights, making them a go-to for large-scale projects.

Pros

- High lifting capacity, suitable for heavy loads.

- Suitable for rough terrains with powerful engines.

- Extended operational range with large fuel tanks.

Cons

- Noise and emissions, making them less suitable for indoor use.

- Higher operational costs due to fuel expenses.

Optimal Use Cases

Diesel scissor lifts are perfect for outdoor construction projects, particularly those requiring significant lifting power and height reach. They are commonly used in building construction, roadwork, and large-scale maintenance tasks.

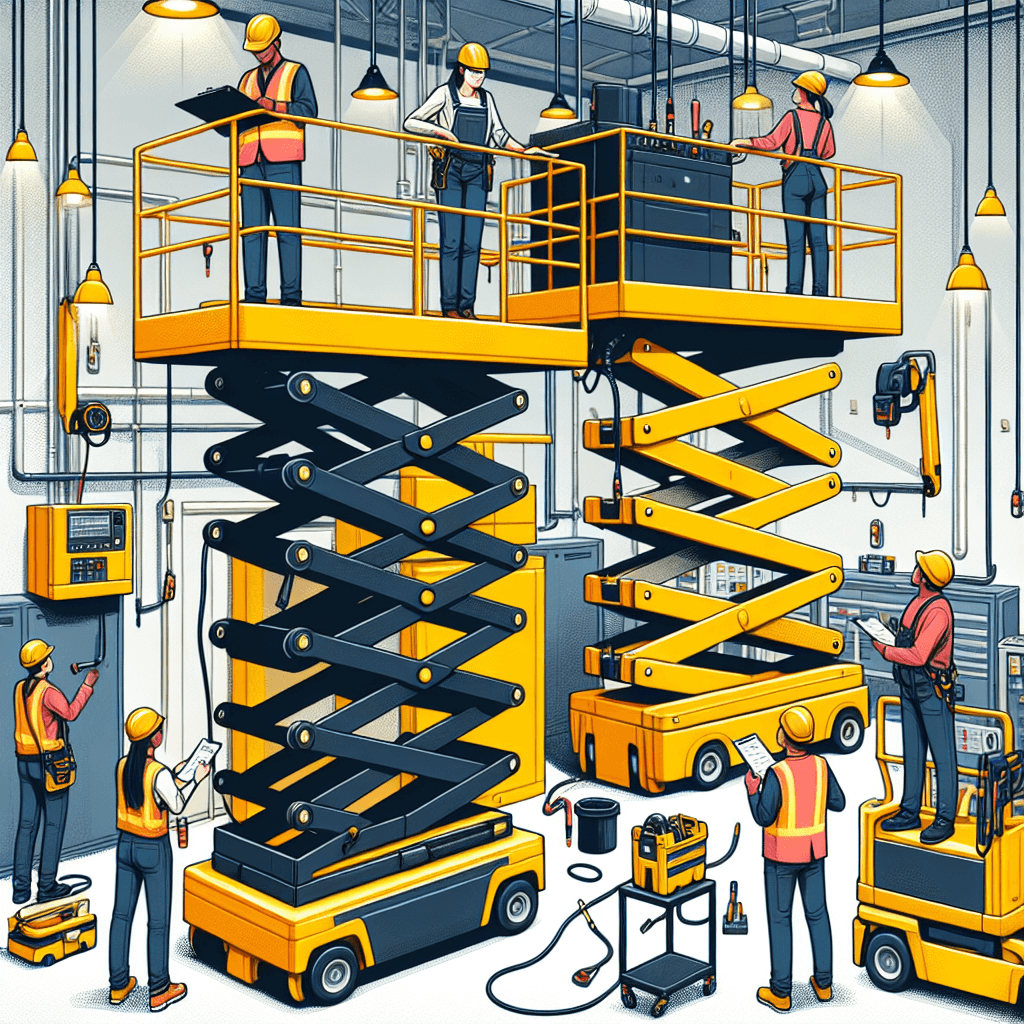

Electric Scissor Lifts

Electric scissor lifts are another popular aerial platform machine. An alternative to burning fuel, electric scissor lifts feature a silent, powered drive mechanism. Since they do not emit fumes or noise, these lifts provide a cleaner solution for indoor spaces, which often have insufficient ventilation.

Their compact design allows for easier maneuverability in tight areas, making them ideal for jobs in warehouses, maintenance tasks, and indoor construction projects. With models available that can reach heights comparable to diesel lifts, electric scissor lifts balance performance with environmental considerations, providing a versatile option for modern construction needs.

Key Features

Rechargeable batteries power electric scissor lifts, making them eco-friendly and silent. They are often used in indoor settings where noise levels and emissions need to be minimized.

Pros

- Quiet operation, ideal for indoor use.

- Zero emissions, making them environmentally friendly.

- Low operational costs with rechargeable batteries.

Cons

- Limited power compared to diesel lifts.

- Shorter operational range, requiring frequent recharging.

Optimal Use Cases

Electric scissor lifts are best suited for indoor construction tasks, such as electrical work, painting, and ceiling installations. Their quiet operation and zero emissions make them a favorite in warehouses, offices, and retail spaces.

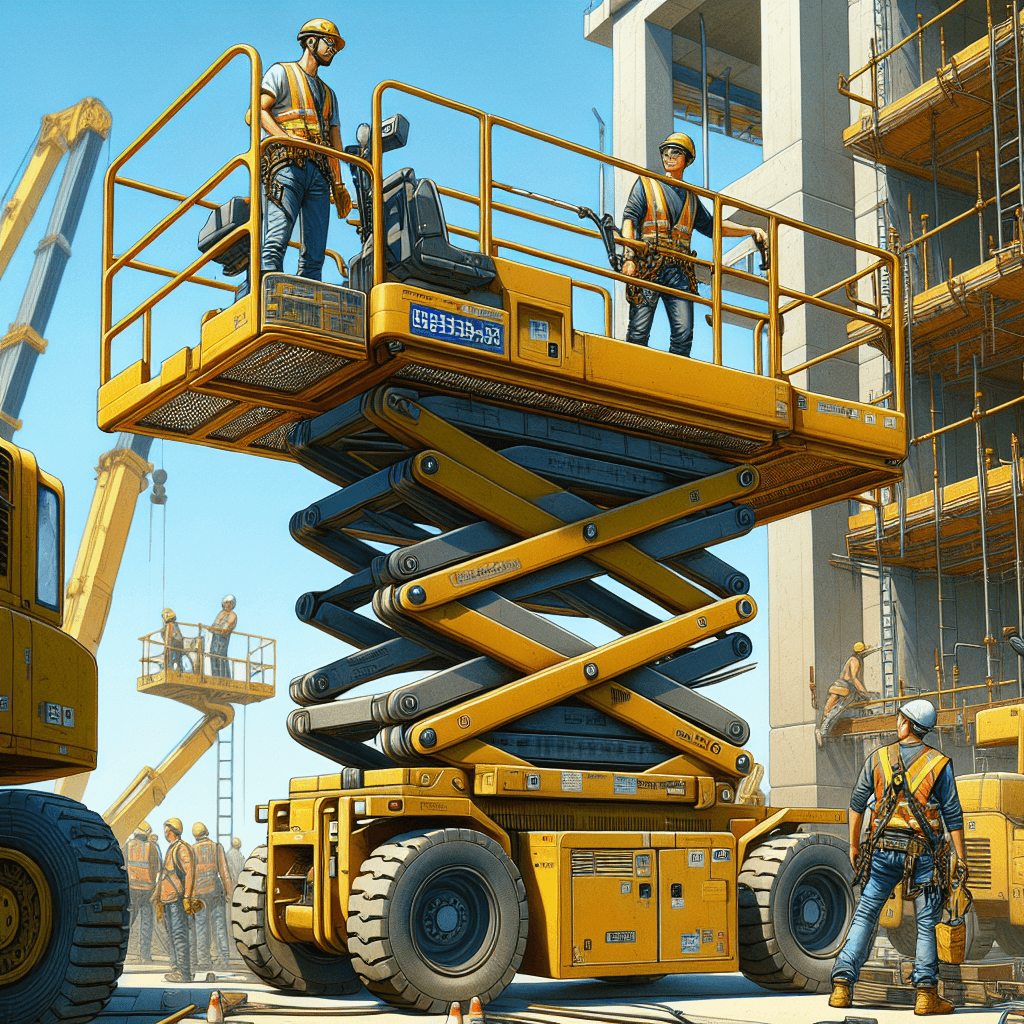

Rough Terrain Scissor Lifts

Rough terrain scissor lifts are specifically designed for outdoor applications where the environment can be challenging. These lifts are equipped with heavy-duty tires that provide enhanced traction and stability on uneven surfaces. With a high-weight capacity and additional safety mechanisms such as fall restraints and arrestors, they ensure that operators are secure while working at height.

Capable of reaching elevations of up to 50 feet and widths of up to 10 feet, rough terrain scissor lifts are particularly advantageous for projects taking place in inclement weather, where standard lifting equipment may struggle. They can adapt to the unique requirements of various job sites thanks to their flexibility in using fuels like diesel, gas, liquid propane, or dual fuel.

Key Features

Rough terrain scissor lifts are designed for challenging outdoor environments. Equipped with heavy-duty tires and powerful engines, they can handle uneven surfaces and steep gradients.

Pros

- Superior stability on uneven terrains.

- High load capacity, suitable for heavy construction materials.

- Extended height reach, making them versatile for various tasks.

Cons

- Larger size, requiring more space for operation.

- Higher operational costs with fuel consumption.

Optimal Use Cases

Rough terrain scissor lifts are ideal for outdoor construction sites with challenging conditions. They excel in projects like building construction, bridge maintenance, and landscaping, where stability and power are essential.

Pneumatic Scissor Lifts

Pneumatic scissor lifts use air pressure as their lifting mechanism. Compared to traditional lifts, these models do not emit hazardous fumes or by-products into the environment, making them a more sustainable option for companies looking to minimise their carbon footprint. A pneumatic scissor lift operates by vacuuming and compressing atmospheric air to raise and lower the platform.

While they do not provide as much power as rough terrain or diesel lifts, their versatility allows them to be used in nearly any environment, including indoor facilities. This feature makes pneumatic scissor lifts ideal for applications where quiet operation and eco-friendliness are crucial.

Key Features

Pneumatic scissor lifts use air pressure to operate, making them environmentally friendly and safe for use in hazardous environments. They do not require hydraulic fluid or fuel, reducing the risk of leaks and emissions.

Pros

- Eco-friendly operation with no emissions.

- Safe for hazardous environments, reducing fire risks.

- Low maintenance, with fewer mechanical components.

Cons

- Limited lifting power compared to hydraulic and diesel lifts.

- Slower operation speed, making them less efficient for quick tasks.

Optimal Use Cases

Pneumatic scissor lifts are perfect for environments where safety and eco-friendliness are priorities. They are commonly used in industries like pharmaceuticals, food processing, and cleanroom manufacturing.

Real-World Examples of Scissor Lifts in Action

Scissor lifts have proven their worth on numerous construction sites around the world. Here are a few examples:

- High-Rise Building Construction: In New York City, hydraulic scissor lifts were used to install glass panels on a new skyscraper, significantly improving worker safety and efficiency.

- Warehouse Maintenance: A major logistics company in London employed electric scissor lifts to repair and replace ceiling lights, reducing noise disruption and maintaining a clean environment.

- Bridge Repair: Rough terrain scissor lifts were utilized in rural areas of Canada to perform essential maintenance on aging bridges, ensuring stability and access even on uneven surfaces.

Best Practices for Selecting the Right Scissor Lift

Choosing the right scissor lift depends on several factors:

- Terrain: Consider whether the lift will be used indoors or outdoors, and the type of surface it will operate on.

- Height Requirements: Assess the maximum height needed for your tasks.

- Load Capacity: Determine the weight of the materials and personnel the lift will need to support.

By evaluating these factors, you can select the most suitable scissor lift for your specific needs, ensuring both safety and efficiency on the job site.

Future Trends in Scissor Lift Technology

The future of scissor lift technology looks promising, with several trends set to impact the construction industry:

- Automation and IoT Integration: Scissor lifts with advanced sensors and IoT capabilities will offer real-time data, improving safety and efficiency.

- Electric and Hybrid Models: As environmental concerns grow, the demand for electric and hybrid scissor lifts will increase, reducing emissions and operational costs.

- Enhanced Safety Features: Future scissor lifts will likely include advanced safety features like automatic stabilization and collision avoidance systems.

The Difference Between Scissor Lifts and Boom Lifts

Understanding the differences between scissor lifts and boom lifts can help you choose the right equipment for your project:

- Scissor Lifts: Offer a spacious platform, better stability, and higher weight capacity. Ideal for vertical tasks and indoor use.

- Boom Lifts: Provide precise maneuverability, extended arm reach, and are suitable for outdoor tasks where horizontal access is needed.

How to Operate a Scissor Lift

Operating a scissor lift is straightforward but requires attention to safety. Follow these steps:

- Familiarize Yourself with Controls: Review the manufacturer’s handbook and inspect the control panel.

- Take Safety Precautions: Wear appropriate safety gear and conduct a safety inspection.

- Turn on the Scissor Lift: Disengage the emergency stop buttons to activate the controls.

- Position the Scissor Lift: Switch on “drive mode” and use the joystick to move.

- Situate the Platform: Use the joystick to adjust the height, checking for overhead obstructions.

- Turn Off When Done: Lower the platform, engage safety mechanisms, and shut down the lift.

OSHA Standards for Operating a Scissor Lift

Adhering to OSHA standards is crucial for safety:

- Guardrails: Ensure scissor lifts have guardrails to prevent falls.

- Stability: Ensure lifts are stable and won’t tip over.

- Positioning: Avoid crushing or electrocution hazards.

- Electrical Training: Provide training for work near electrical sources.

- Maintenance: Regularly maintain lifts to ensure safety.

- Worker Training: Train workers on safe operation and nearby work.

Conclusion

Selecting the right scissor lift for your construction needs is crucial for maintaining safety and efficiency. By understanding the different types of scissor lifts, their features, and optimal use cases, you can make informed decisions that enhance productivity and ensure worker safety.

For more tips on selecting the right equipment and staying updated on industry trends, explore our resources and join our community of construction professionals.

Ready to elevate your construction game? Sign up and discover more insights on vertical access solutions today!