Sector-Specific Scissor Lift Designs: Gearing Up for Unique Industry Requirements in Construction, Maintenance, and Warehousing

Scissor lifts are the mainstay of safe elevated access in the least possible time and cost in different industries and their very unique feature and scissor lift designs of stability combined with vertical elevation stands out as the main factor that basically led to the use of these lifts in the construction, maintenance, and warehousing sectors with prominent scissor lift designs.

One can also spot how scissor lifts cater to the needs of each sector via customized features and new scissor lift designs which in turn leads to the right selection of a piece of equipment and the maximum of both safety and productivity at the different localities of work.

Environmentally Challenged Scissor Lifts in Construction: Toughened Devices for Tough Terrains and Heavy Loading

Scissor lifts in a construction environment are supposed to deal with situational challenges: uneven ground, heavy materials, and changing weather conditions. Rough terrain scissor lift designs have been specifically designed to perform these jobs. They are equipped with heavy-duty tires, a reinforced stability system, and have an enhanced lifting capacity so that the lifts with the best scissor lift designs which can safely take the workers, tools, and materials over some rough outdoor surfaces that can be quite long.

- Heavy-Duty Tires and All-Terrain Capabilities: These lifts are equipped with powerful tires that can maneuver through mud, gravel, slopes, and debris that are typical of construction areas.

- Greater Lift Heights and Platform Sizes: In order to provide room for several workers or heavy machinery, the construction models offer amplified platform areas as well as increased maximum lift height (up to 60-70 feet).

- Power Options for Harsh Conditions: Generally, gas or diesel engines are chosen for outdoor use, as they provide more power and longer working hours compared to electric models.

Constructors also enjoy safety features brought about by the use of slip-proof self-leveling platforms, outriggers, and emergency descent systems. Such features help the operator feel secure when working on unsteady grounds. By using proper set of scissor lift designs for outdoor work, the time spent not working can be cut down, project demands can be met, and safety standards of the OSHA for aerial work platforms can be complied with.

Role of Scissor Lift Designs in Maintenance:

- Maintenance Scissor Lifts: Multi-functional, Space-saving, and Energy-efficient for Indoor Jobs

- Scissor lifts for maintenance should be able to go through limited indoor areas of a building, provide smooth mobility, and accurate vertical access.

- Electrical scissor lifts have the major share of this market because they are noiseless, produce no emissions, great scissor lift designs, and their components have a small footprint.

- Compact Maneuverability: Usually, electric scissor lifts are of such a small size that they can easily be moved around warehouses, office buildings, and production facilities even in the presence of narrow aisles or limited space.

- Smooth, Quiet Operation: The electric motors of these machines allow them to produce very little noise which is important in an environment that is still like offices or retail stores.

- Adjustable Platform Heights for Varied Tasks: Maintenance lifts have variable heights to support ceiling repairs, lighting maintenance, or HVAC system access.

Moreover, maintenance lifts also come with safety elements such as guardrails, emergency stop buttons, and sensors that help in accident prevention. The feature that makes them capable of movement even when the platform is in the raised position helps a lot in the rapid execution of tasks since the time taken to prepare a new location or reposition is very short—this being a crucial factor for rapidly changing maintenance workflows.

Warehousing Scissor Lifts: Facilitating the Efficiency and Safety of High-Density Storage

Warehousing is highly facilitated by scissor lifts that are engineered for the efficient picking of customer orders, shelving, and stock handling. Such lifts assist in space and workflow optimization in high-density storage areas.

- Large Load Capacities for Goods and Personnel: A warehouse scissor lift can enable several workers and at the same time hold the cargo that is to be transported thus allowing the task of pallet stacking or repair at high places be done quickly.

- Electric Drives with Tight Turning Radius: These indoor logistics- scissor lift designs lifts can easily go through narrow aisles and high-bay shelving thus giving great flexibility to the operators.

- Platform Size and Height Customization: One can choose to have a platform that is extendable to increase working area for complicated stocking or equipment repairs.

Besides making time efficient in the sense that less time is used to go up and down ladders, warehouse scissor lifts also make work safer by providing workers with a stable platform thus lessening the chances of falling. Their noise-free electric operation is in line with the requirements of indoor environmental conditions and features such as overload sensors and emergency descent that uplift the confidence of the operator are also in place for regulatory compliance.

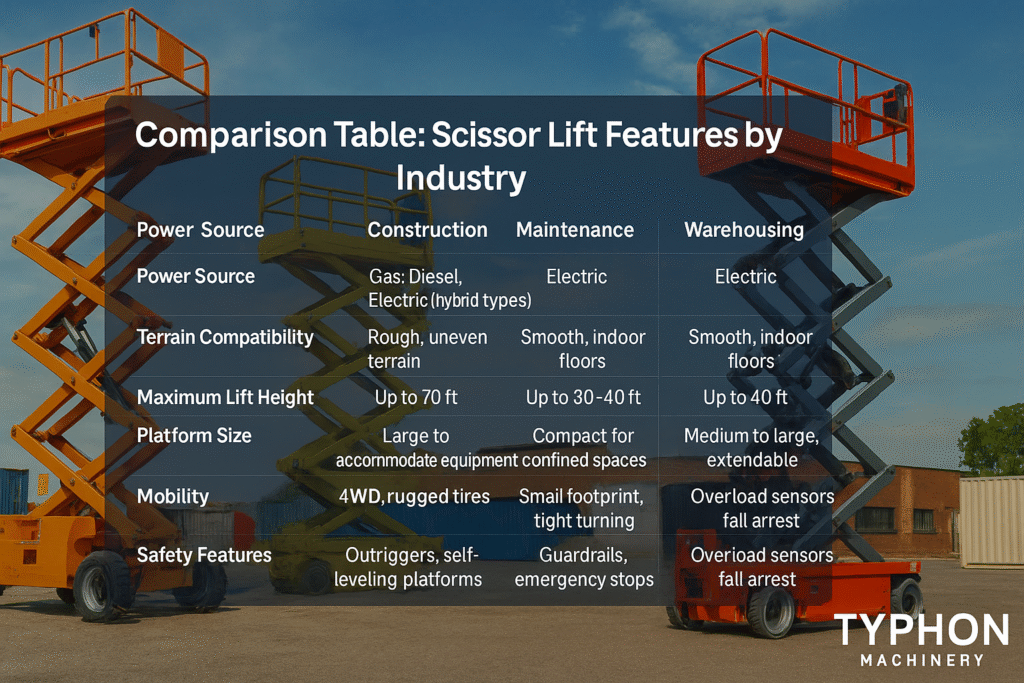

Comparison Table: Scissor Lift Features by Industry

| Feature | Construction | Maintenance | Warehousing |

| Power Source | Gas, Diesel, Electric (hybrid types) | Electric | Electric |

| Terrain Compatibility | Rough, uneven terrain | Smooth, indoor floors | Smooth, indoor floors |

| Maximum Lift Height | Up to 70 ft | Up to 30-40 ft | Up to 40 ft |

| Platform Size | Large to accommodate equipment | Compact for confined spaces | Medium to large, extendable |

| Mobility | 4WD, rugged tires | Small footprint, tight turning | Tight turning radius |

| Safety Features | Outriggers, self-leveling platforms | Guardrails, emergency stops | Overload sensors, fall arrest |

| Ideal Use Cases | Outdoor construction, maintenance | Indoor maintenance, repair work | Order picking, shelving, stock handling |

Customization and Bespoke Scissor Lift Solutions

More and more businesses are utilizing personalized, made-to-measure scissor lift designs that are specifically created to meet their operational requirements. These modifications may involve changing the size of a platform, using a different control system to facilitate automation, installing extra safety features, or upgrading existing units with new modules to increase their capabilities.

- Automotive Industry: Heavy-duty scissor lifts created for the ease of handling large parts or entire vehicles.

- Logistics and Manufacturing: Scissor lifts that are connected to inventory management systems and fitted with barcode scanners.

- Film and Event Production: The use of ultra-quiet lifts and smooth controls for the easy and precise movement of the camera and the set.

The next thing after that is to talk about how such safety measures, productivity methods, and workflow integration work together to turn the scissor lifts into multifunctional tools that can appropriately react to sector-specific challenges by simply designing them to be industry-tailored.

Essential Safety and Training Considerations

Safe operation of scissor lifts needs proper operator training according to OSHA and ANSI regulations. Training involves:

- Pre-use inspections and hazard identification

- Handling loads and observing weight limits

- Safe operation tips and emergency procedures

- Correct use of personal protective equipment (PPE)

Training programs help to improve the skill levels of the operators, lower the number of accidents, and ensure that the necessary workplace rules are adhered to, which is very important for all the industries which use scissor lifts.

Sector-Specific Scissor Lift Designs Engineered for Better Industry Needs

In short, scissor lifts with sector-specific scissor lift designs are literally changing the way the three sectors of construction, maintenance, and warehousing work. These lifts that are engineered to satisfy the different demands of each industry help to promote safety, efficiency, and, in the end, a higher level of productivity.

By their specially designed features, employees are enabled to perform their work more comfortably, hence, the possibility of accidents is thereby reduced and the level of job satisfaction is elevated. Accordingly, as a consequence of the ongoing chain of industry standards, there is a need for technology to be constantly updated as well.

Firms willing to take a step toward the modernization of their operations should be ready to make such a purchase as a specialized lift solution in order to keep their competitive advantage and be compliant with the latest regulations.

FAQ’s – Sector-Specific Scissor Lifts Designs:

What sorts of scissor lifts will be most practical for construction sites?

A rough terrain scissor lift powered by either gas or diesel, large platforms, and rugged tires will be perfect for construction.

Can scissor lifts be utilized in the interior for maintenance?

Yes, electric scissor lifts are the best choice when it comes to indoor maintenance because of their small size and silent operation.

Is it safe to move a scissor lift when it is in the elevated position?

It is possible to move a scissor lift while it is elevated but this should only be done in accordance with strict manufacturer guidelines and safety protocols.

At what intervals should scissor lifts be inspected?

A daily pre-use inspection and a regular scheduled maintenance are the main conditions for safe operation.

Could the industries interchange a scissor lift just by modifying them?

One answer is yes. It is a trend that different industries have their specially made scissor lifts with different safety, control, and platform features.

Which training should the operator be trained to operate a scissor lift safely?

Operator training should be a compliance with OSHA standards and include safety, inspection, and operating procedures.

By what means are warehouse scissor lifts helping to raise productivity?

Time is saved, the work becomes less physically demanding, and the efficiency of order fulfillment is enhanced by providing fast and safe access to the high shelves.