What Are The Top 5 Benefits Of Vertical Mast Lift? Efficiency in Tight Spaces: Scissor Lifts

Indeed, it is the equipment choice that sets one of those finishing the project ahead of time and the other one that delays the project. Large boom lifts and scissor lifts are the most common pieces of equipment that you see on sites, but they may not be the best if you need access to a narrow, congested area. Thus, a vertical mast lift can be an answer to such a situation.

These small, nimble lifts are a completely different category. The vertical mast lift benefits that can be very useful when you have to work in a cramped area are the following:

Vertical mast lifts are compact, flexible, and fast. Due to significantly reduced footprints, vertical lifts are the most effective and the best solution for indoor work, such as maintenance from suspension or stock picking, on the finishing level when the space is tight.

The trend towards more efficient warehousing and retail environments with denser layouts drive up the demand for equipment offering the perfect combination of reach and a compact profile. Here are some of the greatest advantages of using a vertical lift:

Top 5 Advantages of Vertical Mast Lift

1. Superior Maneuverability in Confined Spaces

The most apparent vertical mast lift benefit is that the lift itself can move in spaces where other lifts cannot since it has a zero inside turning radius. It can rotate 360 degrees in such a tiny area that an operator turning inside a narrow lane of a store, a crowded warehouse, or a jam-packed construction site can do it without the need for extra space. This feature not only saves time on repositioning the machine but also facilitates the operator’s concentration directly on the intended work.

At the same time, the vertical mast’s physical size has been tailored to fit the existing infrastructure. Most models are sufficiently narrow to go through a standard single door and fit inside passenger elevators.

- Zero-Degree Turning: Able to rotate in very small spaces, perfect for warehouses where there are a lot of things stored.

- Standard Doorway Fit: Engineer to Fit 30-32 Inch Wide Openings with No Requirement for Modification.

- Elevator Accessibility: Light and small enough to be carried by standard elevators in multi-story buildings.

2. Enhanced Operator Safety and Stability

The main logic for getting rid of old-fashioned ladders and going up to powered access alternatives is finally safety, a criterion that the vertical mast lift benefits score highly in. To be more specific, vertical mast lifts provide a fully enclosed platform with rigid guardrails, whereas ladders depend only on the user’s balance and offer absolutely no fall protection which makes the risk is very high.

Additionally, the stability provided by a heavy chassis and a vertical mast system contributes to less swaying, which in turn gives operators a sense of security and enables them high performance while working at height.

Another feature that modern lifts have is that they are constantly loaded with the help of active safety systems. The principle of works such machines is that various sensors are used to detect problems that may occur and immediately inform operators and service technicians. One of the examples is that if the machine is on an unsafe slope, the lift platform will be locked to safety.

- Fall Prevention: One of the major benefits that vertical mast lifts has over ladders is the fully enclosed and egress protected platform.

- Active Monitoring: Safety features include sensors that assess tipping risk and platform loading.

- Pothole Protection: Pothole protection system automatically engages when the platform is raised to minimize risk of tip over.

3. Precise Positioning and “Up-and-Over” Reach

The primary job of a vertical mast lift is to move the platform vertically up and down, but depending on the model there is also the possibility of reaching another dimension – horizontal. This is where the jib comes in, which is a boom attached to the mast and the platform that can be moved vertically by a winch that is located beneath the platform.

Besides being able to see and touch the product without having to acquire the closest opening in the shelf and the vertical lift only meaning the vertical lift approach and letting the space on the shelf for the third measure is missing out that elevates work efficiency by allowing “up and over” movement.

In the case of vertical mast lifts with no jib, the precision is nonetheless impressive. Usually, the drive controls are proportional so the farther the joystick is pushed, the more the machine’s speed increases. When operating close to fragile surfaces or costly stock, this enables the operator to make very slow and smooth movements.

Such accuracy in controls is absolutely necessary in places like data centers or museums where even a slight bump might cause damage. A mast also gives better visibility than a scissor stack allowing the operator to see the floor and surroundings perfectly.

- Horizontal Reach: Those units that have a jib can provide access over obstacles, thus raising the working envelope.

- Proportional Controls: Smooth acceleration and deceleration for inch-perfect positioning.

- Clear Visibility: The operating view is largely unobstructed by the mast at travel height.

4. Eco-Friendly and Clean Operation

With ever-stricter regulations on the environment, vertical mast lift benefits range into eco-friendliness. Thus, they are mostly battery operated, powered by electric motors which do no directly produce emissions. Such lifts can thus be used safely inside occupied hospital buildings, schools, and food processing plants where the quality of the air has to be preserved.

Compared to internal combustion engines, the main advantage here is that there will be neither exhaust fumes nor noise to struggle with, so the work shall immediately start without the neighboring businesses being disturbed.

Moreover, “clean” also refers to the floor not the air when it comes to vertical mast lifts. Indeed, it turns out that the standard non-marking tires on the majority of vertical lifts are just a great way of ensuring that you don’t leave black marks on polished floors such as those in gymnasiums, or on tile, or on polished concrete.

- Zero Emissions: Energy efficient battery power is ideal for indoor use and certified green buildings.

- Non-Marking Tires: Floor surfaces such as gymnasium floors are protected from scuffs and damage.

- Low Noise Pollution: The machine is so quiet that one hardly hears it, making it suitable for use at any time even the regular business hours.

5. Cost-Effectiveness and Efficiency

The greatest features of vertical mast lifts in the context of financial analysis come out in their efficiency and the fact that they cost less. Getting hold of a vertical mast lift by either renting or buying it will most probably turn out to be cheaper than getting a larger boom lift or a rough-terrain scissor lift.

Also, because they weigh less, the expenses connected with their transportation are additionally going to reduce as they can be moved on smaller trailers or trucks. Thus, the contractor’s lower overhead leads to being able to offer more competitive maintenance and installation bids on contracts.

Efficiency is achieved through speed as well as battery capacity. The lifts are intended for “duty cycle” use, i.e., they can carry out a number of lift cycles before the next charge.

Thanks to efficient electric motors, an operator can work a full shift without having to stop and recharge the batteries. Besides that, operators are allowed to drive many of the models with fully raised platforms.

This functionality drastically increases the productivity of the tasks that require changing light bulbs in several places or inspecting fire suppression system points along the same corridor ceiling.

- Lower Rental Rates: Usually, you can get a top-quality vertical mast lift at lower cost than an articulating or telescoping boom.

- Drivable at Height: Enable worker to relocate without lowering work platform thus improving productivity.

- Long Battery Life: A full work day can be achieved with a single charge of the battery.

Vertical Mast Lift vs. Scissor Lift

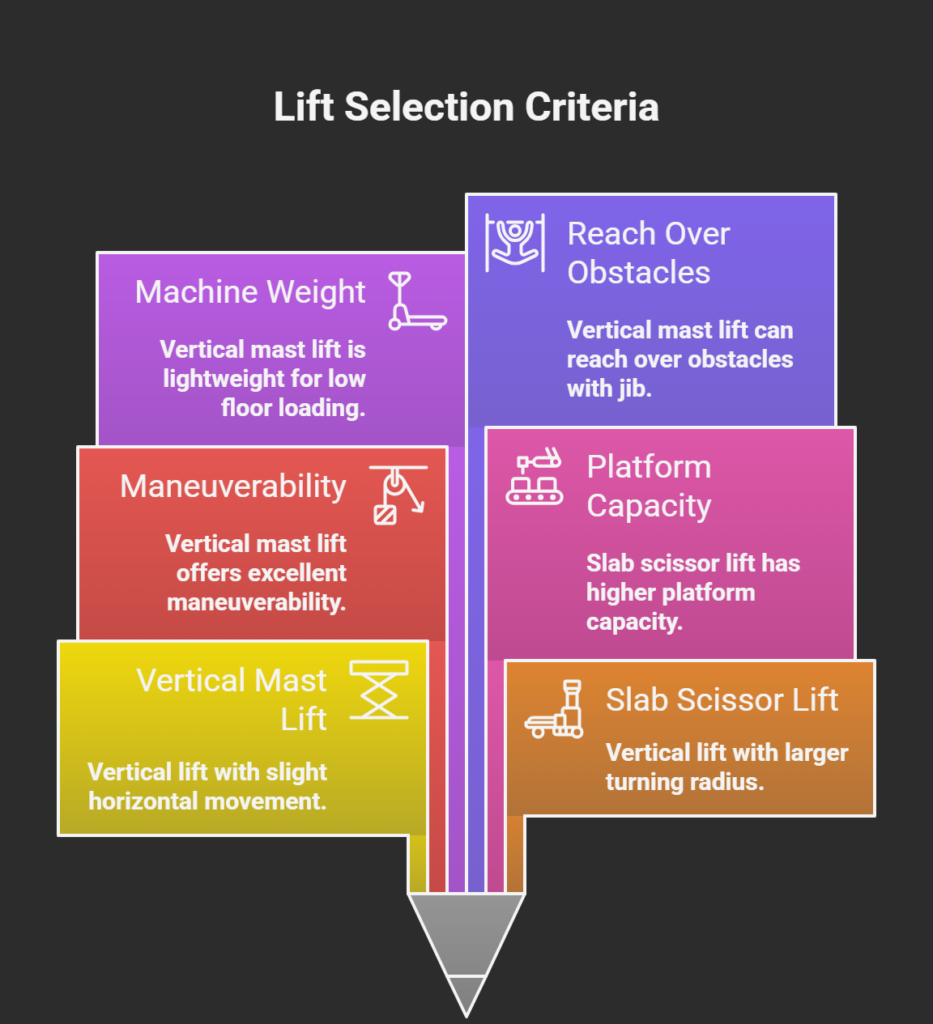

Some of the key advantages and disadvantages between a vertical mast lift and a slab scissor lift are shown below in the table to assist you in determining whether the vertical mast lift may satisfy your requirements.

| Feature | Vertical Mast Lift | Slab Scissor Lift |

| Primary Motion | Vertical + Slight Horizontal (Jib models) | Strictly Vertical |

| Maneuverability | Excellent (Zero tail swing) | Good (Larger turning radius) |

| Platform Capacity | Low (350 – 500 lbs) | High (500 – 1,000+ lbs) |

| Machine Weight | Lightweight (Low floor loading) | Heavier |

| Reach Over Obstacles | Yes (With Jib) | No |

| Entry Width | Very Narrow (Fits single doors) | Standard (Fits double doors) |

Scissor Lift FAQs – Vertical Mast Lift

What is a vertical mast lift used for?

Vertical mast lifts are the go-to option in a variety of both confined space and indoor construction activities, maintenance and warehousing. Examples include changing light bulbs, picking stock, repairing facilities, working on the ceiling, and the display of signage in a retail setting. They are a great alternative for ladders where there is an added element of danger but scissor lifts are just too big.

How high can a vertical mast lift go?

The average working height of a vertical mast lift is between 12 and 32 ft. The models that get bought most by those working in facility maintenance indoors give the operator a working height of anywhere between 20 and 26 ft., which is more than enough to handle a ceiling at any non-industrial building.

Do vertical mast lifts have a reach?

Indeed, vertical mast lifts are often fitted with a jib extension. It enables the platform to go out horizontally (for 3 to 5 ft, usually) past obstacles. Standard mast lifts without a jib work only by moving the platform up and down similar to a scissor lift only with a much smaller footprint.

What is the difference between a man lift and a vertical mast lift?

A “man lift” is a general term used loosely to describe any personnel lift including manual push around units. A vertical mast lift is a specific kind of self-propelled personnel lift with a telescoping mast. The main difference between them is that the vertical mast lift is powered and drivable whilst some “man lifts” must be pushed into position.

How much weight can a vertical mast lift hold?

Typically, these lifts have a rated payload capacity of 350-500 lbs which enables them to carry one operator plus his/her tools or light components. Unless it is planned to use the lift for heavy pallets or multiple workers simultaneously, in which case a scissor lift should be chosen, these machines are not intended to be used for carrying heavy loads.

Can you drive a vertical mast lift while it is raised?

The majority of the new self-propelled vertical mast lifts allow you to move the lift while the platform is elevated. Nonetheless, when the mast is extended the machine will automatically restrict the driving speed to the characteristic that is classed as “safety creep” speed in order to avoid accidents.

How much does a vertical mast lift weigh?

The machines have a very low weight in comparison with other types and usually weigh between 1500 and 2500 lbs. This allows their use on delicate flooring and in upper stories of buildings where there are limits on floor loading that can easily rule out heavier scissor lifts.

A Scissor Lift Verdict: Vertical Mast Lift

To sum up, the vertical mast lift benefits make such a lift the must-have gadget for any modern-day industrial agency. By providing the missing link between unsafe ladders and bulky construction equipment, this type of lift manages to come up with the perfect balance of safety, accuracy, and productivity.

Its main characteristics are its ability to access tight spaces, its environmentally friendly run, and its budget-friendly rental prices. At the same time, this makes it the leading and preferred choice for any facility manager and contractor alike.

Should your next job be one where you will need to combine working at height with the use of a tight and congested environment, then the best mode of reaching the job site using a vertical mast lift is what you want. Here at Scissor Lifts we advise you to focus on safety and efficiency by picking the most suitable machine for the job.