How to Retrofit Your Scissor Lift with Smart Sensors for Remote Diagnostics

Installing smart sensors for remote diagnostics on your scissor lift is a major overhaul that brings your machine into the modern digital era of Industry 4.0. Smart sensors provide you with the real-time monitoring feature, predictive maintenance and remote troubleshooting safety measures that reduce downtime and improve operational efficiency. So, how to equip your scissor lift with smart sensors technology? It is a simple answer that will set you apart in maintenance effectiveness and make you immune from the occurrence of costly breakdowns.

Let’s breakdown – How to Retrofit your Scissor Lift with Smart Sensor in the below form.

What Are Smart Sensors and Remote Diagnostics?

Smart sensors are small devices installed on the most stressed parts of the scissor lift which work in a continuous mode and measure such parameters as load weight, platform height, tilt, hydraulic pressure, and machine health. Having these small devices on the machine means the operator has less work to do as these devices themselves collect operational data and send it over wireless communication to cloud-based platforms, thus enabling remote diagnostics by the technicians. Using AI-technologies and analytics, the system can notify of any problems at an early stage, anticipate failures and provide an extensive list of possible courses of action for the staff to perform preventive maintenance.

- Machine-condition sensors capture live data related to meningela, pressure, tilt, temperature, and loading.

- Information Streams are IoT platforms for remote representation via centralized dashboards.

- The main A.I. algorithms — advisory services and maintenance systems — use Data for analysis, issuing immediate notifications and generation of junctures for issue resolution.

Integration of scissor lift with smart sensors such a unit deeply elevates performance and safety standards of scissor lifts, among examples, in the construction, maintenance, and event-production fields.

Benefits of Retrofit Scissor Lift with Smart Sensors

Refitting your present scissor lift set with intelligent sensor devices is an account of many benefits, which directly affect the operational efficiency, safety, and maintenance costs of the company.

- Reduced Downtime: The round-clock monitoring of the state allows the implementation of predictive maintenance, which keeps away unexpected breakdowns by finding the root causes of the situation way ahead of time.

- Enhanced Safety: Using the most straightforward examples, like easy-to-install tilt and load monitors, operators get immediate notifications about the aggravation of the workplace and overload situations, resulting in accidents caused by additional load or unstable ground.

- Cost Savings: Remote diagnostics means that there will be less visit by the technicians on the site thus leading to the reduction in service costs and the accelerating of repair times.

- Data-Driven Decisions: Several metrics reports on usage and maintenance derived from large databases must have been collected by the fleet management system to be useful for real-time decision making, for example, turning each piece of equipment into a living entity averaging its lifespan.

By committing to retrofit solutions, companies slowly transit from reactive maintenance scenarios to proactive, data-based asset management models.

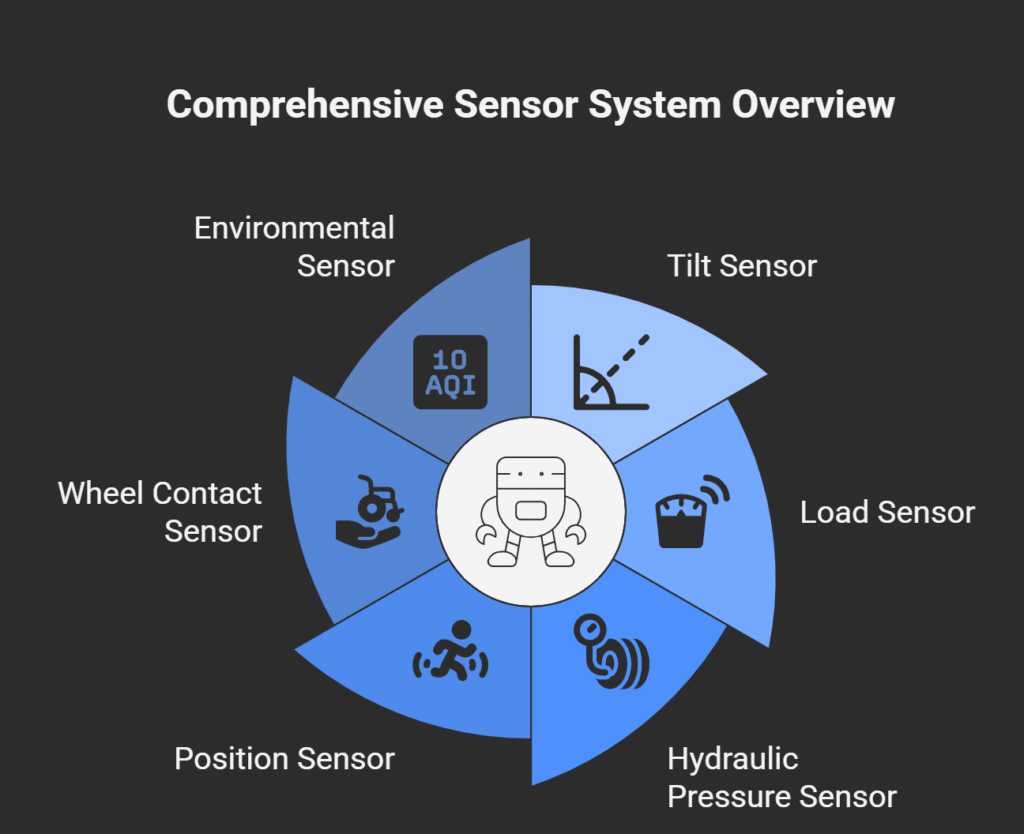

Types of Smart Sensors Suitable for Scissor Lift Retrofitting

There are numerous sensor components that result in an overall remote diagnostic system for scissor lifts. The safety enhancement and error detection cortisol-potency highly depend on the selected devices.

- Tilt Sensor: Identify an angle of the device towards the ground surface to prevent usage on steep and dangerous areas which can ultimately lead to loss of stability and tip-over accidents.

- Load Sensor: An instrument that performs weight measuring of the structure platform thus establishes a limit concept for the device preventing overloads that cause instability of the system.

- Hydraulic Pressure Sensors: Determine the tightness and regularity of the hydraulic fluid chamber responsible for powering lifting operations.

- Position Sensors: Accurately Recording knowledge of the heights of the platform and their changes.

- Wheel-to-Ground Contact Sensors: Guarantee the proper contact of the wheels with the ground, and if it is unstable or uneven, they send a warning signal.

- Environmental Sensors: Help in recognizing the atmosphere characteristics such as temperature, humidity, or dust that can either slow down the machine or interfere with sensor function.

Every one of these devices supplements distinctive ideas which, jointly, make up a comprehensive, detailed, and effective scissor lift safety, as well as supply access for diagnostics.

Step-by-Step Guide to Retrofit Your Scissor Lift with Smart Sensors

Installation of smart sensors on a scissor lift needs a deep thought and accuracy but can be done if you have an expert guide or a professional installer by your side.

1. Assessment and Selection:

- Assess the compatibility of the sensor hardware with your current fleet of vehicles.

- Pick the devices that best meet your requirements giving first priority to the safety areas of concern such as tilt and load.

- Look at the features of modular retrofit kits that provide simple and easy installation.

2. Installation:

- Install the sensors at the most appropriate places like the bottom, platform, hydraulic cylinders, and control panels.

- Make sure the sensors are firmly attached and that they are in a safe place from which they can be exposed to natural elements.

- Link the sensors to an onboard controller or IoT gateway device.

3. Integration with Remote Monitoring Systems:

- Connect sensors to cloud computing solutions that enable data provision in real-time.

- Create software dashboards that technicians and fleet managers can access.

- Set up alert levels and diagnostic regulations tailored to your devices and operational standards.

- Testing and Calibration:

- Run tests to check proper functioning and sensor precision.

- Adjust the calibration of the sensors to manufacturer-defined sensitivity levels.

- Teach operators how to use sensor feedback displays and safety warnings.

- Ongoing Maintenance and Updates:

- Keep the sensor firmware and the monitoring software up-to-date on a regular basis.

- Plan your sensor check-ups and recalibration on a regular basis.

- Monitor the sensor data trends for continual performance enhancement.

Example Table: Sensor Functions and Benefits

| Sensor Type | Function | Benefits |

| Tilt Sensor | Measures angle of the platform | Prevents tip-over incidents |

| Load Sensor | Measures weight on the platform | Avoids overloads, ensures stability |

| Hydraulic Pressure Sensor | Monitors hydraulic cylinder pressure | Early detection of leaks or failures |

| Position Sensor | Tracks platform height and movement | Precise control and safety |

| Wheel Contact Sensor | Detects wheel-ground contact status | Warns of unstable or uneven ground |

| Environmental Sensor | Measures temperature, humidity, dust level | Protects sensor and machine health |

Integrating Retrofit Scissor Lift with Smart Sensors Into Maintenance Workflows

Smart sensors provide remote technicians as well as fleet managers with the opportunity to set up efficient maintenance workflows:

- Remote Diagnostics: Technicians get the information about the latest updates and sensor data that help them to diagnose the problem correctly without presence at the site.

- Predictive Maintenance: Data analytics forecast component wear, scheduling reparations prior to the breakdown.

- Mobile Access: The usage of smartphone apps for lift-condition monitoring in real-time, therefore, can speed up the reaction time.

- Compliance and Reporting: The sensor logs grant conformity to safety standards such as OSHA and ANSI, thus, helping the audits.

Without interruption, the maintenance groups can be very quick in taking actions along with accurate diagnostics of the deep-seated cause which is a result of higher machine uptime and better safety standards.

Common Challenges and Solutions During Retrofit

Confounding the art of implementing smart sensors on previously existing scissor lifts with possible troubles that, however, could be solved by thorough preparation in advance:

- Compatibility Issues: The old lifts might have to be equipped with the adapter kits or customized sensor mounts to fit the modern requirements.

- Data Connectivity: The most faraway places may be dependent on the installation of cellular or satellite communication to be able to send data.

- Sensor Calibration: The devices must be accurately calibrated to prevent the false alarms as well as undetected situations because of the wrong calibration.

- Operator Training: Making operators aware of the proper reading of the sensor’s signal is paramount both for the security and the ease of utilization.

Pro-level retrofit players will guide you through these barriers towards a successful sensor update.

How Retrofit Advances Align with Industry 4.0 Trends

Contributing to the digital transformation and IoT, Industry 4.0 is indeed a great helper in the process of construction and industrial maintenance. So, retrofitting a scissor lift is like a piece fitting perfectly in this puzzle:

With the help of digital transformation and IoT, the 4th industrial revolution (Industry 4.0) is changing the face of construction and industrial maintenance. The upgrading of scissor lifts is an excellent example of how these changes can be used to:

- Allow smart asset management with up-to-the-minute transparency.

- Make possible the use of predictive analytics to lead maintenance that is low in costs without sacrificing the quality of the service.

- Enhance safety through the use of automated systems for hazard detection and issuing alert notifications.

Such innovations bring your scissor lifts to the leading edge of contemporary equipment management, thus making a considerable return on investment through operational excellence.

FAQs on Retrofit Scissor Lift with Smart Sensors

- Can smart sensors be installed on any scissor lift model?

Generally, sensor retrofit kits are made to be universal, but it is still necessary to verify the compatibility of the lift’s brand and model before mounting.

- How do smart sensors improve scissor lift safety?

One of the methods is by constantly informing about. Such unsafe loads, tilt angles, or hydraulic failures through the issuance of alerts that in turn, assist the user in the prevention of accidents and aiding in the provision of safety ensured operation conditions.

- What data do smart sensors typically monitor?

Such data include platform height, load weight, tilt angle, hydraulic pressure, wheel contact, and environmental conditions such as temperature and dust.

- Is remote diagnostic data secure and private?

Surely, good systems utilize encrypted cloud platforms and follow stringent cybersecurity measures to maintain the security of machine data and that of operator.

- How much does it cost to retrofit a scissor lift with smart sensors?

Costs depend on the kinds of sensors and the complexity of the system; however, the investment is usually paid off by the reduction of the downtime and the maintenance costs.

- Can retrofitted sensors reduce scissor lift downtime?

Yes, definitely. The early fault detection allows for repair scheduling in a proactive manner thus, the unexpected breakdowns and the idle times are kept to a minimum.

- Are there specific standards for sensor-based remote monitoring?

Certainly, the installation usually abides by the safety rules and norms of such organizations as ANSI, OSHA, and the manufacturer’s guidelines ensuring safety and regular operational conditions.