Slab Scissor Lift: What They Are, Where To Use Them & Benefits

The industrial environments of the future will require higher levels of precision, safety, and efficiency than ever before. Among those tasks that really rely on these three factors is reaching and working at height. There exist various types of aerial work platforms to facilitate such work at height, slab scissor lift being one of them.

A slab scissor lift is an engineering marvel of a more specialized nature, specifically designed for use on paved, flat, and level surfaces. If you take care of a high-capacity warehouse, work as an indoor construction project manager, or do commercial facility maintenance, knowing the ins and outs of these machines will be very helpful for your success.

We provide in-depth information at ScissorLifts.org on vertical lifting systems such as slab scissor lifts intending to equip you with knowledge that will enable you to choose well for your worksite.

A slab scissor lift differs primarily in that it has solid non-marking tires and a compact frame which makes it capable of going into very tight spaces indoors without harming or damaging delicate floorings.

On the other hand, rough-terrain workers are equipped to handle mud and gravel, hence the difference from slab lifts or a.k.a. “indoor specialists”. In order to ascend steadily in a vertical direction, these lifts deploy an X-pattern support structure called a scissor stack, which acts like a signature. Stability as the main feature of their design offers a safer and more productive mode of reaching height compared to using ladders or scaffolds.

A large platform space for workers and tools is made available by these lifts, hence enabling the carrying out of even the most complicated tasks with very little downtime and utmost safety.

What is a Slab Scissor Lift?

A slab scissor lift is a variation of mobile elevated work platform (MEWP) that is constructed to perform the task of lifting on smooth, flat hard surfaces like concrete slabs, asphalt, or tiled floors. They run mostly on electricity hence are quiet and non-polluting which is one of the requirements in most cases when work is done indoors. It is basically about having the “slab” tag to signify the fact that the machine needs a flat surface as a base in order to keep the center of gravity within safe limits at heights.

- Non-Marking Tires: Fitted with solid rubber tires that will not mark epoxy, tile, or polished concrete floors by leaving scuff marks.

- Pothole Protection: Steel guards incorporated that open automatically when the platform is raised and prevent the machine from tipping in case the lift goes over a small floor depression.

- Electric Propulsion: The batteries are charged by deep-cycle battery banks and last for a full day with no exhaust pollution.

Main Uses and Benefits of Slab Scissor Lifts

Its adaptability is what has made a slab scissor lift become essential in a vast spectrum of industries. When it comes to projects where lining up the machine under the work area is feasible, these machines would be the ones preferred since they provide a pure vertical lift. Because of their small size, they can get through standard double doors and even squeeze through narrow warehouse aisles where it is impossible for larger equipment to go.”

- Warehousing & Distribution: Get the right equipment to manage inventory, pick stock and provide repair to rackings at heights in your logistic centers.

- Facility Maintenance: Make fixing LED lights, repairing HVAC ducts and carrying out sprinkler system inspections much easier with the use of these machines in malls, schools, and hospitals.

- Indoor Construction: Let the installation of electrical wiring, surface painting, and plaster board tasks go uninterrupted with these lifts that are absolutely perfect wherever these agencies are involved in the later stages of construction of a project.

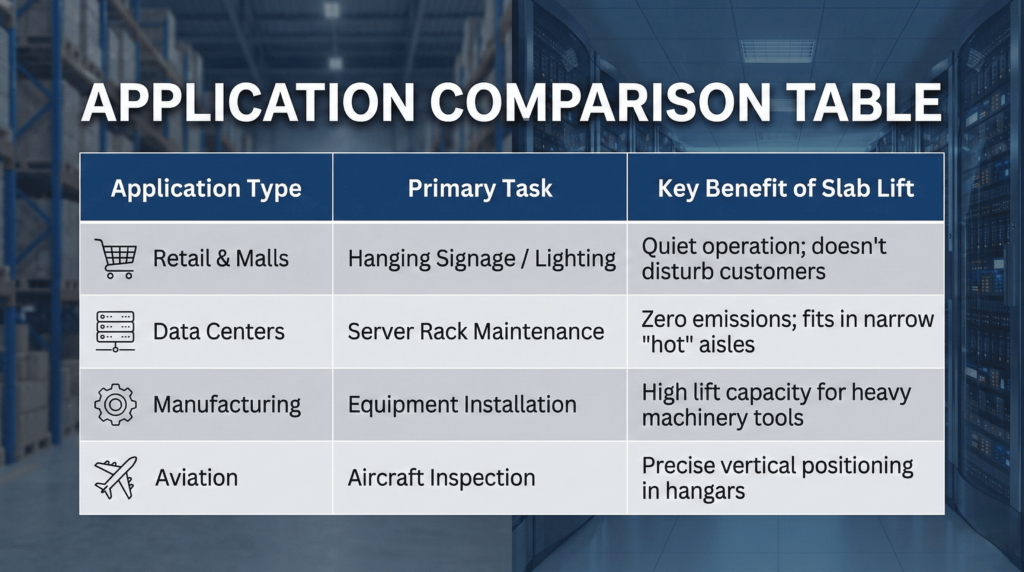

Application Comparison Table – Slab Scissor Lift

| Application Type | Primary Task | Key Benefit of Slab Lift |

| Retail & Malls | Hanging Signage / Lighting | Quiet operation; doesn’t disturb customers |

| Data Centers | Server Rack Maintenance | Zero emissions; fits in narrow “hot” aisles |

| Manufacturing | Equipment Installation | High lift capacity for heavy machinery tools |

| Aviation | Aircraft Inspection | Precise vertical positioning in hangars |

Top Gains from Slab Scissor Lift Usage

Investing in a slab scissor lift can guarantee safety plus return on investment more than manual climbing methods or other types of aerial platforms. Designed to help “human fatigue” be put at bay, you no longer need to use a ladder to get to the next level.

Moreover, the fact that the operator can drive the lift with the platform still being partially raised (on even ground) means that there is no interruption in the work process when the task extends over a very long distance of ceiling or wall.

- Operator Safety Significantly Improved: Features such as 42-inch high guardrails, emergency stop buttons, and tilt sensors come together to provide a safety level that ladders simply cannot match.

- Productivity Greatly Raised: Large platform allows multiple workers and heavy tools (up to 1,200 lbs depending on the model) to be lifted at the same time, thus, less trips down and up.

- Environmentally Friendly Operation: As most slab models are 100% electric, they support “Green Building” programs and meet the requirements of indoor air quality regulations that are very strict.

Important Characteristics that Need to be Taken Into Account

When making a choice from ScissorLifts.org you will be looking at a machine whose features are a perfect match for the requirements of your job site. The wrong choice of a lift such as one with lower height or overloaded can bring safety violations plus delays in the project.

The majority of the slab lifts have heights varying between 19 and 45 feet. Their widths are mainly limited between 30 and 46 inches to make sure they can go through standard doors.

- Platform Height vs. Working Height: Always keep in mind that “working height” is usually 6 feet higher than “platform height”.

- Extension Decks: A good number of models offer a “slide-out” deck feature which gives an additional 3 to 4 feet of horizontal reach beyond obstacles.

- Gradeability: Although designed for flat slabs, most machines can handle a 25% to 30% grade (ramps) when they are in the stowed (lowered) position.

Maintenance and Durability

You cannot expect to have your slab scissor lift as one of your reliable companions for work if you do not carry out regular maintenance. In fact, since such machinery use mainly hydraulic and electrical systems, periodic maintenance and checks not only prevent minor problems but also avoid major and expensive repairs.

A nicely kept and therefore efficient electric lift has a service life of above 10 years thus turning it into a very cost-saving device for the facility manager.

- Battery Care: Always make sure that distilled water levels in lead-acid batteries are checked frequently and that the battery is fully charged overnight.

- Hydraulic Inspections: Check for leaks around the piston cylinders and give the fluid a good look to avoid valve clogging.

- Annual Inspections: Following OSHA and ANSI standards which prescribe the certification technician procedures for the thoroughness of the physical and functional check, every 13 months.

Safe Use of Slab Surfaces

Since slab scissor lifts are extremely stable by design, they should not be considered as absolutely safe. Most of the accidents that happen are due to operator error while ground conditions are ignored.

It is a rule without exceptions that lifts have to be only raised on level surfaces. Even a short sloping area can make the tilting alarm go off, which shuts down the raising as well as driving features automatically so that a tipping is avoided.

- Pre-Operation Check: A daily walk-around check is a must for the operator to detect tire damage, oil leaks, and operating emergency controls.

- Weight Distribution: The load should be always kept in the center of the platform and the rated capacity on the manufacturer’s data plate must be strictly adhered to.

- Clearance Awareness: Before elevating, you should constantly be looking for overhead obstructions such as power lines, low-hanging pipes, or ceiling fans.

FAQs – Slab Scissor Lift

Are slab scissor lifts suitable for outdoor use?

Indeed, but only with the highest level of caution. Using them outdoors is permissible on concrete pads or finished asphalt slabs only. However, they should not be operated on dirt, grass, or gravel at all. On top of that, operators have to take into account wind ratings because most indoor-rated lifts are not intended for use in windy outdoor conditions.

In what technical ways do slab lifts differ from rough terrain ones?

The foremost distinguishing features of the two types include tires as well as chassis. A slab lift is equipped with solid non-marking tires and its ground clearance is low for indoor usage whereas a rough terrain (RT) lift is equipped with big foam-filled lug tires, 4-wheel drive, and has higher ground clearance to counter mud and uneven outdoor sites.

Is a license required for the operation of a slab scissor lift?

The answer is yes, but not a driver’s license one. What is required instead is a certification (frequently it is an AWP/MEWP card) confirming that an operator has done the requisite training (both theoretical and practical) for the elevated work platform category in which the lift belongs. This is the requirement for any operator according to OSHA in the United States.

When it comes to an electric slab lift, how long does its battery power last?

In a typical “duty cycle” situation (lifting and driving intermittently), a battery that has been charged fully will be able to power a full 8-hour work shift. Or you can say the heavier the usage and the longer the driving distance, the sooner the battery runs out of charge. A complete or 100% charge usually takes 6 to 8 hours.

What is the size of a mini/micro scissor lift?

The micro scissor lifts are the smallest ones and they usually have a platform height ranging between 10 and 14 feet. They are perfect for office spaces that are being renovated because they fit into passenger elevators and can go through standard single doorways.

Is the scissor lift capable of tipping over?

A careless user can cause this to happen although it is very unlikely. Some common causes being the platform being loaded beyond its limit, working on an uneven surface, or being “caught” by moving overhead crane. However, modern lifts come out equipped with tilt sensors and pothole guards which greatly reduce chances of such incidence to occur.

What is the maximum weight limit of a slab scissor lift?

The vast majority of standard slab lifts feature a lift capacity of 500-1,200 lbs. The amount of weight a slab lift is allowed to carry is enough to accommodate two workers plus a reasonable quantity of tools or materials. However, you must always refer to the “Safe Working Load” (SWL) of your particular model.