Introduction to Scissor Lift Mechanism

The scissor lift mechanism is considered one of the most adaptable lifting systems, which is commonly seen in different areas of industries.

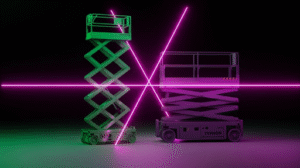

It offers a good and steady method of raising or lowering heavy items. Linked, folding supports implemented in a crisscross “X” pattern, also known as a pantograph, are the base on which the scissor lift device is conceived. The simple but effective device by itself, is a common solution for load handling in warehouses, factories, construction sites and, medical fields, etc.

Actually, the scissor lift structure is an instrument of efficiency, innovation, and adaptability rather than just a lifter. Scissor lifts are utilized in various ways and as a result, they have made themselves vital part of the equipment.

Their modernization was extremely influenced by the hydraulic, pneumatic, and electric systems, thus they are now easier to be managed, and they are safer and stronger.

One can almost compare a scissor lift to the mechanical innovation which enhances human abilities. We can use those methods to reach high places like ladders or scaffoldings, but they are not totally safe and take a significant amount of time to be organized.

The design of a scissor lift is compact and foldable, thus it reduces manual effort and also enhances safety, which in turn stabilizes. The only difference is, that it’s a mechanical arm that does the lifting work for you in the most efficient way without the risk of slipping or imbalance.

In this section we will learn the concept, significance, and progress of a scissor lift system.

What is a Scissor Lift Mechanism?

The core of a scissor lift mechanism is a unit that is capable to move loads vertically through a system of linkages which are structurally supported and open and close like scissors.

The mechanism usually takes in single or multipoint power for example electrico-mechanical, hydraulic or pneumatic and then it converts the initial movement to a vertical one thereby lifting the scissor unit.

Most important in the mechanism are those support arms or the so called the crossed support arms. If for example we use a hydraulic cylinder the arms spread apart and due to that the platform goes up. In the opposite manner, when the force is taken away, the arms fold back and the platform reaches the bottom.

Some of the most important elements of a scissor lift mechanism are taken from the description below:

- Base frame: The element that gives the whole unit support on the ground.

- Platform: The surface where the load or the operator is placed.

- Scissor arms: The steel bars that are joined at the middle allowing the unit to be expanded and contracted.

- Actuator: The part of the device which changes the energy fed into the system into the form of movement.

- Control system: The system that permits the operator to take control of the lifting, lowering, and safety functions.

The uniqueness of the concept is the main reason why it has not been outpaced by its competitors. The scissor is different from the crane or the boom where the movement is only in the vertical plane giving a very good balance and reducing the possibility of accidents to a very low extent.

The scissor lift mechanism is the heartbeat of the industries where only efficiency and safety are given priority. It can be easily found in all those places where workers need to be lifted to the ceiling for repairs, goods have to be transported from one floor of the warehouse to another or cars are to be lifted in garages.

Importance of Scissor Lifts in Modern Industries

Scissor lifts turned vertical movement in a totally different way and industrial people started to use them instead of ladders, scaffolds, and manual lifts. These are not only the safer and faster but also the more reliable ways to reach the required height. Their imperative nature is such that it is found in different divisions of the areas:

- Construction – The work force is now able to access the upper parts of the buildings without endangering themselves and carry out such works as painting, electrical installations, and hardware attachment etc.

- Warehousing – Lifting heavy items to storage racks at a great height is done in such a way that worker safety is not at risk.

- Automotive – Mechanic workshops are the places where car repair is done with the help of different scissor lifts that are used to elevate the vehicles so that the technical part can be done in the right manner.

- Healthcare – Patient lifts and accessibility platforms have vertical lifting mechanisms and use scissor systems to allow patients with mobility problems to gain access.

- Entertainment – Scissor lifts are widely used in the theater and movie production for the easy handling of lighting, camera setups, and set adjustments by the crew.

Scissor lifts meet the needs of a company by increasing productivity, safety, and the company’s cash flow. They drastically reduce the amount of time that is lost when accidents occur, minimize the physical effort that the workers have to do, and allow for the completion of tasks in a much shorter period of time. It is in such type of industries where these machines become very important.

Just picture the activity of shelf stocking in a huge warehouse and the only vertical apparatuses at your disposal are ladders. The unwieldy process will not only be sluggish but will also pose a great threat to the workers.

By the help of scissor lifts, a worker can take himself and the goods up to the required height and thus making loading work half the time and the other half being assigned for safety purpose.

To conclude, scissor lifts are not complementary any longer but instead, they have become mandatory. They are the ideal choice when it comes to combining the aspects of functionality, safety, and advancement in modern industries.

Brief History and Evolution of Scissor Lifts

Scissor lift technology dates back to the 19th century when it was first introduced with the use of simple platforms that could be elevated to facilitate heavy work.

Besides, the pantograph principle, which is the basic one for the scissor lift, was at first employed in the rail industry to provide electrical power and in the very first mechanical devices to duplicate figures. Later on, the scientists turned the concept upside down to be used for heavy lifting.

During the 1920s and 1930s early types of mechanical scissor lifts were customers in factories, mainly manual and rudimentary screw mechanisms were used for the mart operation of these lifts. The primitive systems were the base for the newly developed hydraulic and pneumatic systems in the sector.

The major change was the introduction of the hydraulics in the middle of the 20th century. The hydraulic scissor lifts were the ones that paved the way for more efficient lifts that could use less human effort, thus the lifts became very popular among repair shops and warehouses. Later on, when the electric scissor lifts arrived, the situation progressed even more.

Today, a prominent scissor lift is one of the following types.

- Electric-powered scissor lifts that are good for indoor operations as they are environmentally friendly.

- Self-propelled scissor lifts which are the type that allows the movement of the device when it is lifted and not the area only.

- The smart control scissor lifts that have implemented sensors and other protective components to avoid overload situations.

- The lightness of aluminum used in frames results in better mobility complemented by the use of lighter materials like aluminum.

The development of scissor lifts is in line with most changes experienced by industrial machines that have evolved radically. Thus, they went from being manually operated to fully automated ones. In the future, there will be a lot of transforming effects to scissor lifts from AI-assisted controls to energy-efficient designs making scissor lifts smarter, safer, and more sustainable.

Core Components of a Scissor Lift Mechanism

All types of scissor lifts, small or large, are made-up from a handful of central parts. The various parts interlock with each other in a smooth and flawless manner to produce a lifting system that is both reliable and efficient. Knowing the main components helps us to get a glimpse of the technology behind this system.

Base and Platform

The base is like the heart of the body as it keeps the whole system stable on the ground. It is the component that lifts the heavy load while at the same time preventing any tipping or the falling of the system. The platform basically is the roof above the workers, cars, or weights.

Technical points are:

- Anti-slip surfaces for the safety of workers.

- Guardrails to prevent falling.

- Design of load distribution to avoid handling of weights in an uneven way.

Crossed Support Arms (Pantograph System)

Panto scissor arms have the most distinctive feature of the mechanism. These consist of sturdy steel bars connected with rivet joints in an “X” shape. Due to the strength of these arms, the platform is lifted or lowered in the desired length.

This can be explained as the:

- Even lifting of the platform.

- Stability of the machine during the operation.

- Easy folding for small space when not used.

Hydraulic, Pneumatic, and Mechanical Actuators

The actuator is the energy giver of the scissor lift. It may be one of the following, depending on the type:

- Hydraulic cylinder: works with pressured fluid to give an easy lift.

- Pneumatic piston: works with compressed air to lift lighter loads.

- Mechanical screw drive: Transmits power through manual or electric means to achieve smaller lifts.

Safety Features

Contemporary scissor lifts are equipped with sensors, emergency stop buttons, and overload protection systems to guarantee operator safety. The controls can be manual, electric, or remote-operated, depending on the model.

Individually, these parts change a basic crisscross design into a robust lifting machine that can perform challenging industrial tasks with safety and effectiveness.

Working Principle of the Scissor Lift Mechanism

A complete knowledge of how the scissor lift mechanism functions would help us understand its wide applicability in different industries. The process is configured in a way that it absorbs a tiny amount of force and outputs a significantly greater one, thus, it becomes possible to raise heavy loads with little input. Fundamentally, the working principle is one of leverage, hydraulic pressure, and the special geometry of the pantograph mechanism.

How the Pantograph Mechanism Functions

The scissor lift’s pantograph is the main cause of the scissor lift being different from other lifts. The crossed metal arms form an “X” figure, which is getting bigger or smaller like the blades of a pair of scissors. The point of the arms base where force is put in, the “X” becomes bigger and therefore the platform over the scissor arms is lifted. At the same time, the release of the force makes the arms get closer and, thus, the platform goes down the ground.

This kind of movement has many merits:

- Only vertical movement helps in the stability of the platform.

- It can be folded in a compact way, so it is very easy to store it when it is not used.

- Even weight distribution alleviates the load on individual parts of the system.

On the same principle as an accordion or a folding ladder. These items being able to expand and collapse without any hitch, the pantograph mechanism also assures an exact vertical movement with no lateral play.

Hydraulic Power and Fluid Pressure

Hydraulics are definitely the easiest way to power a scissor lift. A hydraulic pump forces oil to go into a cylinder, which then pushes out and does the same with the scissor arms. No matter what, the fluid used is incompressible and thus the lift goes on smoothly and steadily.

Hydraulics major benefits are:

- Very high lifting power (heavy loads are no problem).

- Speed can be controlled for safety purposes.

- Minimal operator effort (just a button or lever to be pressed).

Once the operator activates the control switch, the hydraulic pump should the fluid in the cylinder wherein the arms are pushed. To let the lift go down, the fluid is emitted back into the tank and the platform descends smoothly with the help of gravity.

Mechanical Linkages and Leverage

There are scissor lifts that go for the mechanical screw drives or rack-and-pinion systems rather than hydraulics. These gadgets are made with the help of rotating gears, screws, or chains which extend the scissor arms. If they are hydraulics’ less strong counterparts, they can still be a good choice for smaller applications such as lightweight platforms and portable lifts.

One of the strengths in the design of the mechanical system is that it can count on the accuracy and robustness of the parts, yet this comes at the cost of higher manual effort or electric power that is needed for the system to work well.

Energy Sources: Electric, Diesel, or Manual

Scissor lifts are machines that have multiple ways to be powered:

- Electric – A silent, environmentally friendly, and a brand new solution just made for indoors.

- Diesel – Fully loaded with awesome power, just perfect for outdoor work and heavy tasks.

- Manual – Lever-oriented or foot-pump models that are more suitable for smaller areas.

Lifts in this way are able to adjust their measures and be compatible in any field ranging from warehouses and construction sites, even going through medical facilities.

Types of Scissor Lifts

Not all scissor lifts are the same. Their differences can be determined by the power source, design, and application in which case different types of lifts will be suitable. Each has unique weaknesses and strengths thus, they are useful for certain industries only.

Hydraulic Scissor Lifts

One of the most common kinds, hydraulic scissor lifts, work with pressurized liquid to move the scissor arms. They get the credit for being massive in their power, long-lasting, and stable during operations.

Benefits of them are:

- Lift heavy loads (up to several tons) with the power of hydraulics.

- Maintenance is kept at a very low rate.

- Easy to start with the use of simple controls.

You can find these used mostly in storage facilities, repair garages, and building sites.

Pneumatic Scissor Lifts

The oil is replaced with compressed air in the case of pneumatic lifts. They are also lighter and more environmentally friendly as they don’t require a hydraulic fluid.

Incentives include:

- Operational safety and cleanliness (there is no oil spill).

- Companies specialized in highly hygienic fields, like food or pharmaceuticals, can use them as the best-fitting equipment.

- Quick response time.

On the other hand, they are usually less powerful than hydraulic lifts and thus are more appropriate for lighter loadings.

Mechanical and Rack-and-Pinion Lifts

Such lifts may consist of screw jacks, gears, or chains, which are used to move the platform up. Though rare in number, the main feature of these lifts is that they wield power mainly through precision and control rather than lifting force.

Some examples of these are:

- Theater and stage platforms.

- Small workshops with lighter loads.

- Portable lifts for temporally usage.

Self-Propelled vs. Stationary Lifts

These are the scissor lifts that are also different from each other in terms of mobility.

- Stationary lifts – These are the ones that are fixed in a place, used for loading docks, and factories.

- Self-propelled lifts – These have wheels or tracks and thus are able to move while elevated.

The self-propelled scissor lifts are always very handy in big warehouses or in a construction area, where the operators have to move around quickly and often.

Applications of Scissor Lift Mechanisms

The use of scissor lifts is so widespread that it is hard to find a sector in which they are not employed. They are used in different places, such as on construction sites or in hospitals, for different reasons, yet they always secure the safety of the workers and save time.

Industrial Applications in Warehousing and Factories

In warehouses, scissor lifts are the ones that go up to the top of high storage racks and distribute goods of large weights that are packed on different floors. In factories, they can be utilized for the assembling of the machinery, material transportation, and for production line support.

Benefits include:

- Quicker processing of merchandise.

- Lower worker weariness.

- More secure lifting when compared with the use of a ladder or manual handling.

Construction and Maintenance Work

Construction workers are frequently seen employing scissor lifts for:

- Working on out-of-reach walls with paint.

- Connecting the electrical system.

- Performing repairs and maintenance on the ceiling.

As these lifts are equipped with a stable platform, they are much safer than the traditional scaffolding which can be a higher risk for falls and requires time to be set up.

Automotive Repair and Workshops

One type of car lift that is often found in car repair shops is the scissor car lift. For the purpose of inspection, oil change, and repairs, the mechanics can easily perform these works without giving back strain.

Besides that, in comparison with bigger hydraulic lifts, they do not take up a lot of space which makes them suitable for small workshops.

Medical and Accessibility Uses

The scissor lift system is the basis of certain healthcare applications, including:

- Lifts for patients for safe transfers of the individuals.

- Wheelchair lifts for accessibility in buildings.

- Hospital beds that can be adjusted with variable heights.

It both certifies the comfort of the patient and the safety of the caregiver, which is the main reason the mechanism is so popular in various fields.

Advantages of Scissor Lift Mechanisms

Why are scissor lifts so widely used? The main reason is their several advantages that make them a feasible solution for diverse industries.

Versatility and Adaptability

The reason why scissor lifts are found in so many different places is because they can be modified for different purposes. The same core mechanism can be adapted for a worker, a car, or a pallet of goods.

Safety and Stability in Operations

Scissor lifts in comparison with ladders or scaffolding are much safer for the personnel to work on. The features of safety such as guardrails, anti-slip surfaces, and overload protection systems greatly minimize the risk of accidents to a very low level.

Cost Efficiency and Productivity

One scissor lift can do the work of multiple employees who are using ladders, therefore labor and time costs are minimized. The time of performing the task is also sped up.

Compact Design and Space-Saving Benefits

When a scissor lift is not in use, it is easy to fold down to a smaller size for storage or transport. It specifically helps in small workshops and tight warehouses to keep the work area organized.

Scissor lifts are, in fact, the perfect combination of a power, safety and efficiency machine that should be on-board by every company that uses vertical movement as part of its routine.

Limitations of Scissor Lift Mechanisms

Scissor lifts are amazing, but they are not without some restrictions that should be considered before they get implemented in a situation. These limitations are usually associated with the height, weight and operational conditions of the environment.

Height Restrictions

One of the major problem areas of scissor lifts is the limited vertical reach. Differently from reaching outward and upward like the boom lifts, scissor lifts are only allowed to move in a vertical direction. Almost all models can get to the height of 20 up to 50 feet which is more than enough for so many jobs but still not enough to go very high above the ground.

For instance, a warehouse worker who is restocking the shelves may find a scissor lift to be very convenient and sufficient for his tasks. On the contrary, a window cleaner working on the 70th floor of a building will definitely need a boom lift to get up there and not a scissor lift.

Load Capacity Limitations

That being said, scissor lifts are designed to carry heavy loads; however, they do have a particular maximum weight limit that should not be exceeded. When these limits are surpassed, there is a risk of machine failure and injury to the workers. Situations of overloading may contribute to:

- Hydraulic system failure.

- Uneven lifting.

- Structural instability.

Operators should always verify the load ratings provided by the manufacturers and under no circumstances should they sacrifice safety for the sake of convenience.

Operational Speed and Efficiency

Compared with other lifting systems, scissor lifts are typically slower in their raising and lowering operations. The need for frequent repositioning or high-speed operations can thus be a limitation of the device.

Moreover, the folding mechanism can be subject to stability checks which, in the case of a time-sensitive work environment, can result in a decrease in the workflow.

Environmental and Power Constraints

Scissor lifts are affected by their surroundings:

- Electric lifts perform well indoors but might not be efficient on uneven ground.

- Diesel-powered lifts offer vitality in open spaces; however, they also contribute to noise and air pollution.

- Pneumatic lifts require a continuous supply of compressed air, which might not be a feasible option at all times.

These limitations imply that companies must select the most appropriate kind of scissor lift that fits their specific setting.

Design Considerations for Scissor Lift Mechanisms

The scissor lift design will decide its safety, productiveness, and service life. A team of experts and manufacturers have to take various factors into account to come up with a stock of lifts that will satisfy the different needs.

Load-Bearing Capacity

The most essential feature defining the lift’s capacity of supporting different kinds of weights is the very first design consideration. A lift used in a warehouse might have to carry around 4000 lbs, on the other hand, a hospital lift is usually just required to bear the weight of a human body.

Through the calculation of load distribution, designers can confirm the stage will maintain its stability even if the loading is not balanced.

Material Selection and Durability

Production of scissor arms is highly based on the use of either high-strength steel or aluminum. Steel gives off superior strength which is very suitable for the handling of heavy loads, at the same time, aluminum offers the easy-to-carry feature of the product.

Longevity is the main issue as scissor lifts will be used in the harsh industrial sector most of the time. Also, corrosion-resistant coatings are used as a preventative measure against the gradual chipping off of the scissor lift resulting in a longer usage period.

Safety Standards and Regulations

Contemporary scissor lifts should follow a strict international safety protocol such as that of Occupational Safety and Health Administration (OSHA), and American National Standards Institute (ANSI) .

It comprises the following:

- Guard rails

- Available emergency stop buttons

- Overload sensors

- Anti-slip platforms

These technological advances ensure the safety of both the workers and the machine.

Maintenance Requirements

A lift that is designed well is that one which is easy to check, maintain, and repair. Design engineers usually provide lifts with an easily accessible hydraulic cylinder, removable panels, and universal parts to ensure that the machine is out of work for a minimal amount of time.

At the end of the day, successful design really depends on the symbiotic relationship of the aforementioned qualities namely strength, efficiency, and safety, this architectural endeavour thereby ensuring such a device performs well “on the ground” so-to-speak.

Safety Features in Scissor Lifts

When it comes to the problem of working at high altitudes, operators always prioritize safety. However, scissor lifts have been fitted with several safety features that have lowered the risk of danger significantly. These safety measures make them much less risky compared to ladders or scaffolds.

Guardrails and Safety Gates

The protection from falling accidentally is the main function of guardrails that are a must in every scissor lift platform. Safety gates or chains not only prevent the access to the platform but also ensure the workers’ safety during entry and exit without the risk of slipping.

Emergency Stop Controls

The moment an emergency stop control is activated, operators can shut down the whole system in an instance. In case of hydraulic leaks, electrical malfunctions, or unexpected obstacles, the emergency stop call is very handy.

Overload Protection Systems

Contemporary scissor lifts have weight sensors that halt the lift’s operation if the load is above the predetermined safe limit. The safety of workers is a top priority, so, along with this measure, the machine is being partially “shielded” for the accident.

Fall Prevention and Stability Enhancements

Some of the other safety features are:

- Tilt sensors that halt operations if the lift is on an unstable surface.

- Automatic brakes to avoid rolling off by accident.

- Non-slip platforms to increase the frictional force against the ground.

Thanks to these combined safety measures which are nearly invisible to the naked eye, safety becomes one of the most important criteria amongst the different characteristics of scissor lift as one of the most reliable lifting systems in the industry.

Future Innovations in the Mechanism of Scissor Lifts

The scissor lift mechanism has already been revolutionized significantly, yet with the advent of new technologies, there are more incredible future improvements to expect in this field.

Smart Technology Integration

The technology of the internet of things, along with sensors is one of the new features of modern lifts, which has made the operators’ job much easier, as they are able to keep track of load, height, and stability in real-time. The situation of some models is such that they can send a maintenance alert to the mobile phone of the user without any intervention.

Energy Efficiency and Sustainability

Manufacturers are committed to producing environmentally friendly products with the following measures:

- Electric lifts with batteries having longer life spans.

- Charging systems that use solar energy to assist.

- The use of recyclable products for the components of the construction.

Automation and AI-Controlled Lifts

One of the developments that might be seen in the future of scissor lifts is the introduction of self-driving skills that would allow them to move without human assistance around the site of work. AI can be also belped to safety system to prevent the occurrence of accidents making the prediction of the risks prior to the event of an accident.

Lightweight Materials and Advanced Designs

By using lightweight composite materials and advanced manufacturing techniques, companies have been able to reduce the weight and at the same time maintain the same level of strength. This has led to increased efficiency and easier transport.

The future of scissor lifts is indeed the future of technology, environmental protection, and safety as the principles of adaptation to the changing needs of industries around the world are being implemented in designing such equipment.

Maintenance and Troubleshooting

Even a scissor lift, which is a masterpiece of design, needs to be looked after regularly. Good maintenance will not only guarantee the safety of the operator but will also, to a large extent, assure the longevity of the machine.

Common Issues in Hydraulic Systems

- Oil may leak through the excessively worn seals.

- Air bubbles mixed with the oil cause sudden movements of the lift.

- Due to the wearing of the cylinder, the power of lifting diminishes.

Routines of inspecting the equipment help in the early diagnosis of these diseases.

Preventive Maintenance Tips

- Check for signs of oil leakage in the hydraulic system.

- Ensure all safety features are in place before operating the equipment.

- Make sure that the parts that move are lubricated regularly.

- Do the necessary to replace the old parts as soon as possible.

Inspection Checklists

- The stability of the platform.

- The condition of tires or wheels (for mobile lifts).

- The healthiness of the emergency stop function.

- The fluid levels of the hydraulic system.

Repair and Replacement Guidelines

In case of problems, the repair work should be done by trained professionals only. Also, part replacements done with genuine manufacturer components not only solve the problem of ease of use but also extend the durability of the product.

If kept in good condition, a scissor lift can be used for 10–15 years, which makes it an instrument of great value for a company in the long run.

Comparing Scissor Lifts with Other Lifting Mechanisms

Scissor lifts are not the only lifting mechanism that is available even though they are widely used. Comparing them with other lifting systems such as boom lifts, aerial platforms, and forklifts can help in making the right choice for a particular job.

Scissor Lifts vs. Boom Lifts

- Scissor Lifts: Deliver safety and stability when lifted directly to the top. They are ideal for quick tasks in small areas that require only up-and-down movement.

- Boom Lifts: Have the ability to not only extend vertically, but also horizontally, thereby giving more options to the operator to get into the difficult areas.

For instance, scissor lifts are ideal to be used when it comes to warehouse shelving; on the other hand, if we are talking about window cleaning on tall buildings, then the usage of a boom lift would be the best.

Scissor Lifts vs. Aerial Platforms

- Scissor Lifts: Feature large and stable platforms that are big enough for multiple workers and various tools.

- Aerial Platforms: Are comprised of the likes of cherry pickers, which are comparatively smaller and more agile.

While scissor lifts are designed for heavy industrial work, the usage of aerial platforms is limited to light maintenance tasks.

Scissor Lifts vs. Forklifts

- Scissor Lifts: Are made for carrying workers as well as platforms to the desired location.

- Forklifts: Consist of the mechanisms that are able to lift pallets and cargo both horizontally and vertically.

Even though both of them are very important for warehouses, the difference lies in the fact that forklifts are concentrating on moving goods from place to place whilst scissor lifts are designed for fast and safe elevating of people.

Which is Best for Your Needs?

The decision to choose the best lift should be based on a list of requirements:

- If it is a matter of vertically lifting the workers then the best option for you will be a scissor lift.

- If it is the matter reaching the most awkward spaces then the use of a boom lift would turn out to be the best choice.

- If you want to move the heavy cargo in the most efficient way possible then you should definitely go for a forklift.

Companies that grasp these distinctions can prevent making expensive mistakes and properly select the right equipment for the job.

Cost Factors and Purchasing Guide

Buying a scissor lift will require a significant amount of your time and money. Its price varies from three to six figures, depending on the size, the type of the energy source, and extra features. Most organizations want to see the initial payments and the operating costs of the long journey ahead working side by side to make the most efficient use of their hard-earned money.

Initial Investment and Budget Considerations

The price of a scissor lift can go from $10,000 to $60,000, depending on its specifications. Little manual lifts are so cheap, while big, heavy-duty diesel ones are in the mid- to high-end are more expensive.

Things that lead to cost differences are:

- Load capacity.

- Maximum height.

- Mobility (stationary vs. self-propelled).

- Safety and automation features.

Operational and Maintenance Costs

Except the buy, businesses should be ready to spend on the following as well:

- Fuel or electricity costs.

- Routine maintenance (hydraulic oil, filters, tires).

- Replacement parts (cylinders, safety sensors).

On the other hand, a scissor lift in good condition is an asset that can result in the increase of productivity and become self-financing over time.

Rental vs. Ownership

If the project is short, a scissor lift rental will be a better option. Cost generally stands at about $100 to $500 for a day, with the term and size variation being the factors influencing it.

Ownership becomes a better idea in the following cases:

- The lift is used every day.

- The company has professional staff members who are in charge of maintenance.

- Long-term savings are higher than the total amount of the rental expenses.

Choosing the Right Supplier

Don’t be fooled by deals from unverified sellers or shady providers and always buy from manufacturer’s certified dealers or directly from the manufacturers. Consider the below List:

- Warranty coverage.

- After-sales service.

- Availability of spare parts.

- Compliance with safety standards.

Low-quality lifts might be a good bargain if you only consider the first costs, but sooner or later they will become a source of safety hazards and expensive maintenance.

Conclusion

The scissor lift mechanism is a great illustration of design simplicity mixed with tangible application. The crossbar configuration, which can be driven by hydraulics, pneumatics, or mechanical devices, is what qualifies it as one of the safest and most reliable lifting solutions to date.

These devices are imperative in the functioning of scissor lifts that have become indispensable in different fields and are present in industries that have warehouses and factories, the building trades, hospitals, and many more. The combinations of their multifunctionality, security measures, and affordability give them an edge over conventional ladders or scaffolding.

However, they are not without challenges, mainly when it comes to height and horizontal moves. Nevertheless, when applied in the right manner, they can become a great raise of productivity, which is at the same time accompanied by worker safety.

Scissor lifts are becoming smarter and more energy-efficient with each technological advancement, and the promise of even better performance in the future is there.

The knowledge of the scissor lift mechanism will be beneficial to you as a business owner deciding on investing or as a professional using them on a daily basis, as it will make you competent in handling them at their maximum capacity.