Scissor Lift Drywall Attachment: Complete Guide to Enhanced Installation Efficiency

Professionals in construction face considerable problems when installing drywall, particularly when dealing with ceilings and elevated walls. The use of ladders and manual handling consumes a significant amount of time and can lead to a higher risk of injury or property damage. Scissor lift drywall attachments are a game-changer for contractors in the drywall installation process by providing a safer, more efficient process for handling heavy sheets of drywall at elevated positions.

Attachments licensed specifically for this purpose allow workers to operate safely and effectively a true drywall installation platform from a conventional scissor lift. Workers can lift, secure, and install drywall sheets at heights with less physical effort. Therefore, it is crucial for any contractor who is pursuing increased efficiency in drywall installations or repairs to understand the features, benefits, and proper use of these scissor lift attachments.

What is a Scissor Lift Drywall Attachment?

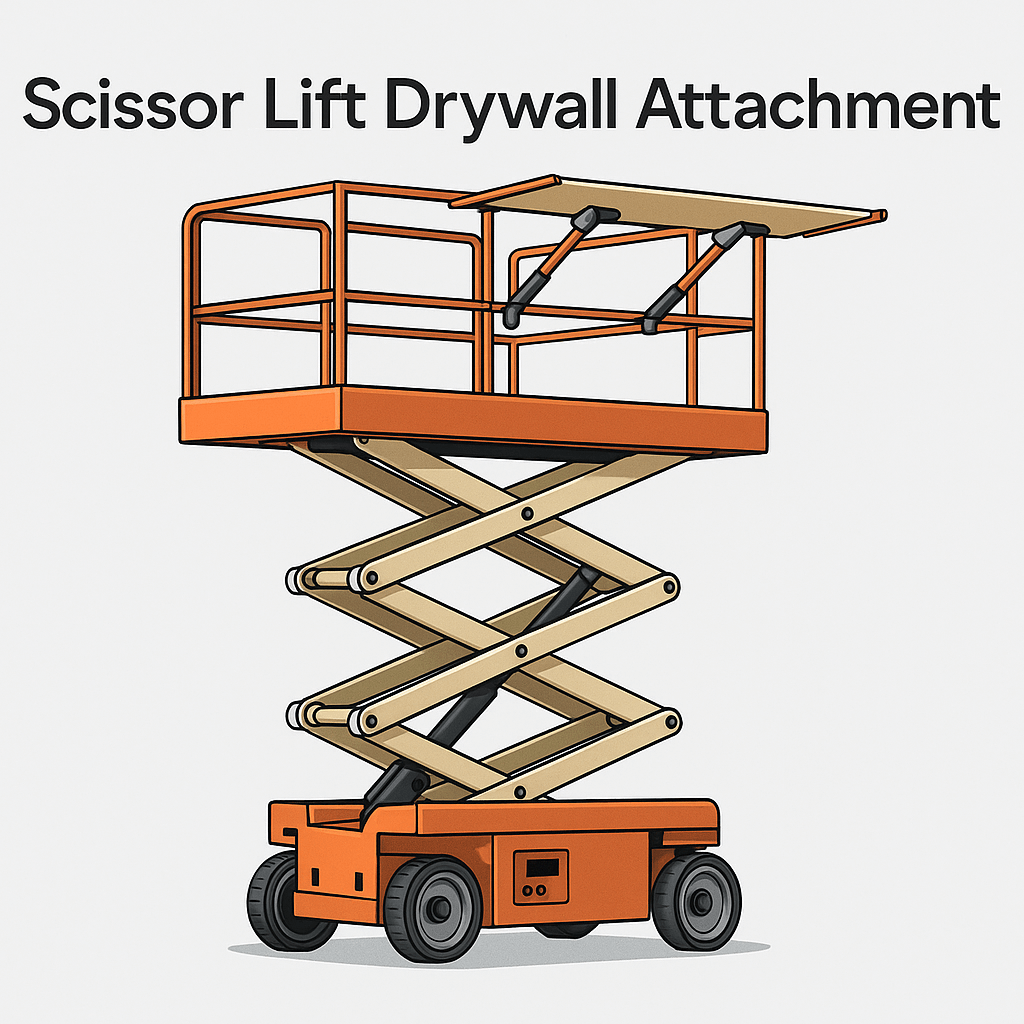

A scissor lift drywall attachment (also referred to as a panel carrier, board carrier), is a dedicated accessory intended to fit onto the exterior of a scissor lift platform. This attachment offers safe storage and delivery of the drywall panels, plywood, glass panes, and other sheet materials as long as the workers work at the height.

Its common design involves a trough or cradle design which is fitted to the outer rails of the scissor lift platform, and on which the panels may be vertically suspended or at an angle during transportation and installation. This arrangement maintains an open working area on the platform deck with the workers, tools, and fasteners allowing the greatest use of workspace.

Key Components

- Mounting brackets: Here the attachment is secured to the edge of guardrails, or platform edges, of the scissor lift.

- Panel support trough: This is a cradle like support to the panels where they will be secure when raised.

- Safety restraints: Straps or mechanical locks which make it impossible to move or fall over the panel.

- Weight distribution system: This is designed to ensure platform stability and balance.

Advantages of Drywall Attachments to Scissor Lifts.

Enhanced Productivity

Among the most crucial benefits of operating with the drywall attachment, it is necessary to mention a tremendous acceleration of the installation speed. Workers are able to carry a number of sheets into the work site in one trip and this saved them the countless trips to the ladders and saved them on the repositioning time. The attachment enables continuous working process, because the materials are easily available at the same place next to the point of installation.

Improved Worker Safety

The manual method of drywall installation involves laborers holding heavy sheets in their hands as they fix them, a very strenuous and risky activity. Drywall attachments have a considerable effect by cutting down on the physical strain on the panel itself by being used to hold the weight of the panel during its positioning and installation. Employees do not have to struggle to keep materials in place but can concentrate on fine tuning and fixing.

Better Material Protection

Drywall sheets are vulnerable to damage during transport and handling. Panel carriers provide secure support that minimizes the risk of corner damage, cracking, or breaking that commonly occurs when sheets are awkwardly maneuvered on ladders or manual lifts. This protection reduces material waste and the costs associated with damaged goods.

Optimized Platform Space

Panels are stored outside the deck of the platform, thus allowing workers to have space to move freely and their equipment. This is a clean working environment and minimizes the chances of trips as well as enabling safe and comfortable working at height.

Versatile Application

Although they are intended to be used with drywall, these attachments can take a variety of sheet goods such as plywood, OSB, glass panes, cement board and other sheet goods. This flexibility renders them useful in various construction and renovation projects.

Types of Scissor Lift Drywall Attachments

Standard Panel Carriers

These are the most widespread attachments with a simple trough shape that is mounted to the exterior rails of the platform. Standard carriers are normally designed to carry up to 250 pounds of panels and may carry several sheets based on their weight and the capacity of the scissor lift.

Heavy-Duty Material Carriers

Heavy-duty carriers are suited to rough terrain and have higher weight capacities, and are constructed using reinforced construction to sustain harsh work site environments. They are the best to be used in commercial construction where there is a lot of drywall to be installed.

Adjustable Panel Holders

There are also more sophisticated models that have adjustable angles and depths in order to enable the workers to optimize the placement of the panels to provide the most ergonomic access and installations. Such connections usually provide other securing measures towards stability.

Key Features to Look For

Load Capacity

Always ensure that the weight bearing capacity of the attachment is appropriate to what you need. It should be remembered that the weight of the attachment, panels, workers, and the tools combined should not surpass the platform rated capacity of the scissor lift. The vast majority of standard attachments are 200-250 pounds.

Compatibility

Not every accessory can be used with each type of scissor lift. Make sure that the attachments are compatible with your equipment by checking the size of the platform, the pattern of the guardrails, and the requirements for the mount. There are some producers who have certain parts for the different models of a machine, and others that have a general system for fixing.

Quick-Mount Design

Time-efficient installation and removal are crucial for rental equipment or multi-purpose lifts. Look for attachments with tool-free or minimal-tool mounting systems that allow quick setup and breakdown between jobs.

Safety Features

Essential safety components include positive locking mechanisms, panel retention straps, and fail-safe securing systems. These features prevent accidental panel displacement during lift operation and transport.

Durability and Construction

Quality attachments feature powder-coated steel construction, corrosion-resistant materials, and reinforced stress points. These characteristics ensure longevity even in demanding construction environments.

How to Use a Scissor Lift Drywall Attachment Safely

Pre-Installation Inspection

Before mounting any attachment, conduct a thorough inspection of both the scissor lift and the accessory. Check for damage, wear, loose components, and proper function of all safety mechanisms. Verify that the scissor lift’s inspection and maintenance are current.

Proper Mounting Procedure

- Set the scissor lift on ground that is both level and stable

- Put the platform down to the lowest level so that access is easy

- Adhere to the mounting instructions given by the manufacturer’s step by step

- Fasten all mounting brackets and if necessary confirm the firmness

- Check the connection for integrity before placing the load on it

Loading Panels Correctly

- Panels should be loaded with the scissor lift platform in the lowered position so that the lifting distance is minimal

- Ensure that the weight is evenly balanced throughout the attachment

- Use all provided straps or restraints to secure the materials

- Do not go beyond the total weight limit

- Check the securing devices before going up

Operating at Height

- Make your move up the lift slow and steady to avoid a sudden jolt

- Operate the scissor lift within its specified angle and stability limits

- Do not overreach or create off-center loads

- Wear the necessary personal protective equipment such as a safety harness and hard hat when required

- Ground personnel should be kept informed through proper communication during the work

Material Removal and Installation

- Use the scissor lift to get panels as close as possible to the spot where they are to be installed

- Only take off the panel that you will be working with

- Have three points of contact with the materials at all times

- Do not throw or drop materials from a height

- After you remove each sheet, make sure the remaining panels are re-secured

Comparing Scissor Lifts vs. Dedicated Drywall Lifts

Understanding when to use a scissor lift with a drywall attachment versus a dedicated drywall lift helps contractors make informed equipment choices.

Scissor Lift with Attachment Advantages

- Makes it possible to raise both employees and equipment at the same time

- Gives workers the opportunity to fix panels from the best height

- Facilitates exact location and change of position during fixing

- If weight capacity is considered, a stable platform can be provided for several workers

- Are not limited to drywall installation only and can be used in other construction tasks

Dedicated Drywall Lift Advantages

- Built only for the easy handling and positioning of panels

- Are able to angle the panels for the walls

- In most cases, less expensive if the project is only related to drywall

- Have a smaller dimension which makes carrying and storing them easier

- Are easy to operate and need only a minimum of training

Optimal Solution

For large projects, many professionals use both: a dedicated drywall lift to position panels against ceilings or walls, paired with a scissor lift to elevate workers to the installation height. This combination maximizes efficiency while minimizing physical strain.

Cost Considerations

Attachment Purchase Prices

Standard scissor lift drywall attachments typically range from $300 to $1,000, depending on capacity, features, and manufacturer. Heavy-duty or specialized models may cost more.

Rental Options

It is possible to rent such a device as a scissor lift with a drywall attachment which is usually offered by most equipment rental companies as an add-on. The additional charge for such a service is usually from 25 to 75 dollars per day. So, if you want to use this device only occasionally, you can afford to use it in a very economical way.

Return on Investment

In general, the implementation of an attachment for productivity purposes on the contractor’s crew working with drywall should pay for itself in only a few projects. The main reasons for such a return are: the reduced labor hours, the decreased material damage, and the improved worker safety.

Maintenance and Care

Regular Inspection Schedule

- Before each use, check the mounting hardware for tightness

- Look over the welds and structural parts for any cracking or damage

- Ensure that the safety restraints are working properly

- Remove any debris and material residue on a regular basis

- Follow the manufacturer’s instructions when lubricating the moving parts

Storage Best Practices

- Keep the attachments in a dry place and protect them from the weather

- Have mounting hardware stored neatly and be able to get it easily

- Put rust-preventive agent on metal surfaces if your place is humid

- Do not place heavy objects on attachments

- Keep a record of the inspection dates and the maintenance done

Manufacturer Options and Popular Models

Several leading aerial work platform manufacturers offer factory-approved drywall attachments designed specifically for their equipment:

Genie Lift Tools Panel Carrier

By using different Genie boom and scissor lift models, these add-ons can hold up to 250 pounds of panels and have secure mounting systems that are designed and tested by the manufacturer.

JLG Panel Carrier

It is possible to mount panel carriers in JLG ES series scissor lifts outside the platform deck that facilitates the transport of material and leaves the work area free.

Skyjack Board Carrier

Skyjack provides board carriers that are compatible with their scissor lift range, have long-life construction, and easy mounting.

Universal Third-Party Options

There are several manufacturers that produce universally fitting drywall attachments that are compatible with the different brands of scissor lifts, thus providing the flexibility of mixed equipment fleets.

Safety Regulations and Compliance

OSHA Requirements

In case the scissor lifts are used with attachments, the operators should follow the rules set forth by OSHA that are as follows:

- Correct training and authorization for the operation of the scissor lift

- When necessary, the use of fall protection

- If the load capacity is specified by a manufacturer, then conforming to these specifications

- By holding on to the guardrails and using the safety systems

- Frequently checking and servicing the machine

Load Capacity Compliance

Never exceed the scissor lift’s rated platform capacity. The combined weight of the attachment, materials, workers, and tools must remain within safe limits. Overloading compromises stability and creates serious safety hazards.

Manufacturer Guidelines

Always follow the scissor lift and attachment manufacturer’s instructions, weight limits, and safety recommendations. Using equipment outside specified parameters may void warranties and create liability issues.

Conclusion

Scissor lift drywall attachments represent a valuable investment for construction professionals seeking to improve drywall installation efficiency, safety, and quality. Panels handling at an elevated level made safe along with their storage with the help of these attachments, the workers become free to concentrate on the exact fixing of the panels instead of wasting their time and energy in handling the material.

While choosing a drywall attachment, first think about whether the attachment will be compatible with your machine, then whether the load capacity will be sufficiently high for the materials you are carrying and lastly, if the safety features are strong enough. Correct training, frequent servicing, and following of safety rules will keep the product in good working condition for a long time and you will get the maximum performance from it.

Whether you’re a contractor tackling occasional drywall projects or a specialist handling large-scale installations, incorporating scissor lift drywall attachments into your equipment arsenal can significantly enhance productivity while reducing physical strain and material waste. These attachments are basically a must-have for any modern construction operation, the three reasons for which are the combined effect of the improved workflow, the enhanced safety, and the better quality of the installation.