Boosting Efficiency with Scissor Lift Attachments: Tool Trays, Deck Extensions & More

It is the main concern for industries and job sites that efficiency should be constantly uplifted in order to sustain productivity, safety, and a competitive edge Thus, the scissor lift attachments instruments—to which tool trays, deck extensions, and altered work platforms can be counted—have spread their influence profoundly over scissor lift functionality and performance in the areas of construction, maintenance, event production, and warehousing.

Unlocking Efficiency: Why Scissor Lift Attachments Matter

Attachments to scissor lifts enhance the basic “lift only” idea to a workflow, safety, and operator productivity–oriented tool unit. The right set of attachments enables the operators to escape the manual scenarios of tools and materials handling, lift repositioning, and random solving, to be able instead to focus on their jobs by:

- Optimize time on the platform by putting the tools and materials that are used frequently close at hand.

- Expand reach and working areas with deck extensions and specialized add-ons.

- Enhance work quality with the help of certain accessories that are made for specific tasks (drywall, electrical, HVAC, signage, etc.).

A productivity-oriented approach results in more tasks being done per day, less physical stress, and fewer delays in the projects. International Powered Access Federation (IPAF) provides evidence that such integration can bring a 30% decrease in task time as compared to the standard methods.

Essential Attachments: Tool Trays

Tool trays are a fundamental upgrade for any scissor lift user. Tool trays are equipped with compartments and holders for hand tools, tools, screws, drills, fasteners, or any other essentials. The tool trays greatly diminish the wasted motion and keep the platforms organized.

- Help avoid the risk of a fall/accident caused by tools that have been left on unsafe surfaces.

- Efficiency is being raised as the operators’ hands are free, and all the key materials are within easy reach.

- Varying trades can use the same tool tray components from electrical installation to drywall work, thus ensuring that the correct compartmentalization is achieved.

The main tool trays give the right contractors and maintenance pros the opportunity to report faster turnarounds—thus jobs are accomplished correctly, safely, and for the first time without the need to go back.

Extended Reach: Deck Extensions

- Deck extensions are the devices that either enlarge the unit’s platform or help the operators to reach beyond the hindrances, thus increasing both safety and output.

- Goes to the extreme of allowing work in the hard-to-reach or blocked areas without having to reposition the entire lift.

- Provides more platform area, thus allowing the inclusion of a larger number of workers along with their tools.

- Helps ceiling installation, wall finishing, HVAC, lighting, and shelving tasks become easier and more efficient, for instance, the JLG Mid-Rail Deck Kit can increase the height of the platform for almost 20 inches.

- Deck extension is a valuable time saver because it can greatly reduce the number of lift repositioning events. Additionally, in large-scale projects, it has the potential to lower man-hours by minimizing lift-and-descent repetitions.

- Specialized Attachments: Beyond the Basics

The development of scissor lift accessories no longer focuses only on trays and deck extension. Present-day machinery can be upgraded by the inclusion of the following features:

- Material racks and clamps, designed for the easy and safe transportation of panels, pipes, or conduits.

- Outrigger stabilizers, used for providing stability on rough terrain in outdoor environments.

- Drywall and glass holding devices, which help in the simplification of facade and overhead installations.

- Platform work lights and power outlets, which ensure a new level of convenience and safety.

The likes of attachments such as the Genie® Lift Tools™ Access Deck is an example of quick conversion for unusual environments and tasks, thus operators can concentrate more on precision and less on downtime.

Safety-First Efficiency: Why Attachments Reduce Risk

Using the right attachment to boost efficiency also implies the promotion of safety at the workplace — a fundamental value of all industries ranging from construction to maintenance. This is how it works:

- There are less goes and returns from the platform thus the number of slip, fall, and collision incidents is minimized.

- Also by having all that is needed at the working height the risk of back strain and fatigue is reduced.

- Attachments that are produced according to the manufacturers’ standards help to keep the stability of the lift and the load rating.

Examples reveal that scissor lift accessories correctly-equipped personnel see a reduction in injuries and lost-time accidents, moreover, it is easier to ensure safety compliance when there are less manual interventions.

Choosing the Right Attachments for Your Application

Deciding on what to choose depends on what your main work, conditions of work, and particular safety requirements are. Some of the major considerations are:

- Kind of work: Electrical, installation, maintenance, finishing, etc.

- Work place: Inside vs. outside, rough terrain, narrow aisles.

- Crew size and work nature: Single vs. multi-worker tasks, heavy materials handling.

Manufacturer compatibility and safety adherence: Always put to use attachments that are at original equipment standard and are certified by manufacturers.

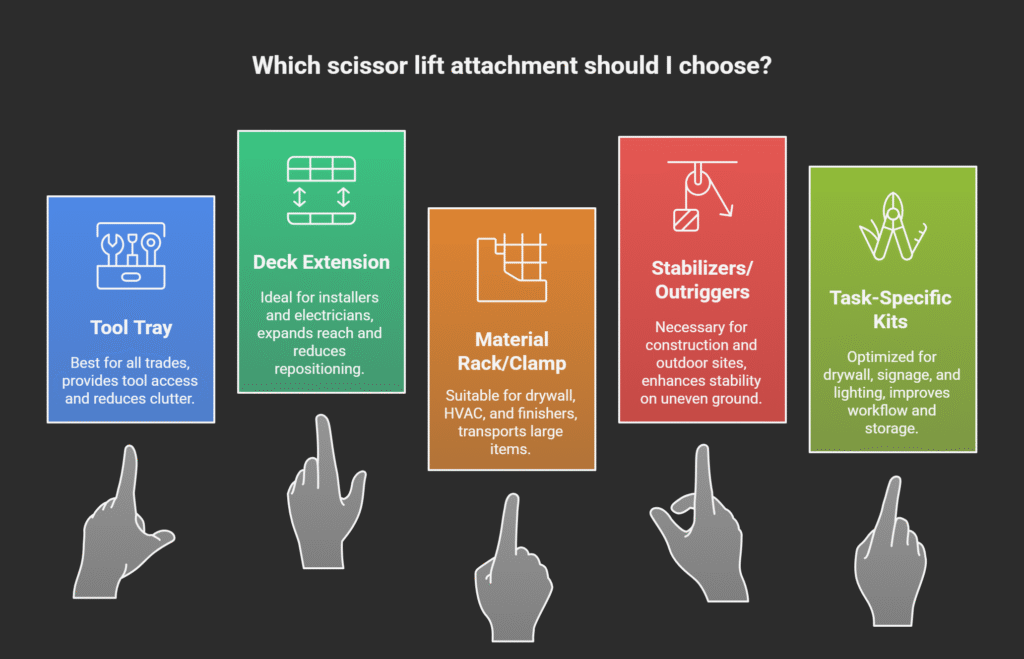

Table: Choose the Right Scissor Lift Attachments

| Attachment Type | Best For | Key Benefits |

| Tool Tray | All trades | Tool access, clutter reduction |

| Deck Extension | Installers, electricians | Expanded reach, less repositioning |

| Material Rack/Clamp | Drywall, HVAC, finishers | Transport of large/bulky items |

| Stabilizers/Outriggers | Construction, outdoor sites | Enhanced stability on uneven ground |

| Task-Specific Kits | Drywall, signage, lighting | Optimized workflow, dedicated storage |

Next-Level Productivity: Emerging Trends

The main trends in the world of scissor lift attachments in 2025 are due to the factors of customization, automation, ergonomic design, and digital integration:

- Automated, robotic-compatible attachments facilitate the logistics and material staging that in turn bring the reduction of manual handling.

- Ergonomically designed trays and platforms work against the occurrence of repetitive strain injuries.

- Intelligent accessories make it possible for data capture and digital safety checks to be done for compliance and preventative maintenance.

- Being in the front line of lift technology means that you have the operator assistance and tool management latest features on your fleet.

FAQs About Scissor Lift Attachments

What are the top attachments for scissor lifts in 2025?

Deck extensions, tool trays, material racks, and digital safety aids are in high demand; each boosts productivity and safety for different job types.

How do deck extensions improve job site efficiency?

By enabling wider or obstructed work areas access and cutting down on the number of repositioning moves necessary, deck extensions bring about faster task completion.

Are scissor lift attachments universal or manufacturer-specific?

Most attachments are built for certain brands or models so as to keep the safety ratings intact, however, there are some universal tool trays or holders; compatibility guidelines should always be checked.

Can any scissor lifts be installed with attachments?

No; The matter of compatibility revolves around aspects such as the design, platform size, weight rating, and manufacturer approvals. Operator manuals or certified dealers should be consulted prior to the provision of accessories.

What safety rules should be observed when using attachments?

Never come even close to the platform’s rated load capacity. Fix the attachments according to the manufacturer direction. Always inspection for correct installation right before the lift operation.

Do attachments influence the load capacity and stability of the lift?

Indeed; Each attachment can have an effect on the maximum weight allowed on the platform as well as the location of the center of gravity. It is advisable to consult with the lift manual or technical support when determining the limits for safety.

Where are the best training facilities for the proper use of attachments by operators?

Among the options for formal training are rental companies, manufacturers, and construction safety organizations; however, it is always better to supplement online learning with hands-on practice.