Introduction to Rough Terrain Scissor Lift

A rough terrain scissor lift is a high degree of precision repair that is required for bent or uneven outdoor surfaces. Consequently, rough terrain lifts have been replaced with standard scissor lifts that are dedicated to smooth indoor floors.

In this case, rough terrain models come with heavy-duty tires, powerful engines, and reinforced suspension systems. Via such setups, they can maneuver effortlessly to various construction sites, a mining area, or even other unstable open-air places where solidity and safety parameters play a crucial role.

Moreover, they use either diesel or dual-fuel engines, for example, which makes them not only able but also strong enough to do so, by lifting the man, tools, and heavy loads to the required heights. Besides, their broad and sturdy platforms also give the opportunity for two or more workers to execute the same or different jobs simultaneously in the allocated space.

In simpler terms, the rough terrain scissor lift can be viewed as the off-road SUV of lifting equipment-while regular lifts are analogous to city cars designed for smooth roads, rough terrain scissor lifts are made to dominate dirt, gravel, mud, and slopes.

What is a Rough Terrain Scissor Lift?

A rough terrain scissor lift is basically a machine for lifting people or materials into the air in a difficult job site or wild terrain. Both lifts make use of the same pantograph “X” mechanism, but structural improvements in the rough terrain version are what render it capable of dealing with uneven and unsteady ground conditions.

This Aerial unit is characterized by:

- Large pneumatic or foam-filled tires that provide a higher degree of traction.

- The height of the ground underneath that allows the vehicle to be acutely avoided as it will not be able to be wetted or get stuck on narrow or rough terrain.

- Four-wheel drive for working in the most difficult terrain.

- Super strong lifting system which can not only support the workers but also the materials.

- Power Source – Normal lifts are designed to run on electric motors, whereas rough terrain lifts use diesel or dual-fuel engines for more power.

- Mobility – Off-road lifts are equipped with all-terrain tires and four-wheel drives, while the latter are confined to flat indoor floors.

- Height and Capacity – Models of rough terrain are usually more robust and can lift more than indoor ones, and they can get higher as well.

- Safety – Additional stabilizers, outriggers, and tilt sensors included in the package as standard in off-road lifts increase safety in case of uneven surface operation.

Multi-Person Work Platforms

- Each of the spacious platforms can accommodate several workers simultaneously.

- As it is, you don’t need so many lifts to be working at the same place.

Limitations of Rough Terrain Scissor Lifts

Although the benefits are numerous, rough terrain scissor lifts still have a few disadvantages.

Higher Fuel Consumption

- Diesel and dual-fuel engines are always in need of refilling.

- In comparison with the electric models, this causes longer operational costs.

Noise and Emissions

- In the case of using these lifts indoors, they are not only noisy but also harmful because they produce emissions.

Size and Storage Issues

- Their larger builds mean that they will need a bigger place for storage and transportation.

Higher Maintenance Costs

- In the case of hydraulic systems, tires, and engines, the maintenance interval has to be shortened.

- Getting spare parts and repairing the machine can be more expensive than the standard lifts.

Safety Features of Rough Terrain Scissor Lifts

When talking about safety, it is the most important aspect that should be considered while operating a rough terrain scissor lift, particularly because they are made for difficult surroundings. In order to keep the workers safe and assure an easy operation, the manufacturers incorporate many built-in features.

Outriggers and Stabilizers

Outriggers are essentially supports that can be extended and so, the lift is secured to the ground which in this way increases its stability. Once they are installed, the machine will not be able to top even if it is on a sloped or uneven land. The stabilizers also help in strengthening the equilibrium of the lift.

Tilt Sensors and Overload Protection

- Tilt sensors prevent the machine from working if an unsafe incline is detected, thus stopping the occurrence of accidents that are caused by operating on steep or uneven ground.

- Overload protection guarantees that the lift will not elevate in case the platform is carrying more weight than it is rated for.

Fall Protection Features

Besides guardrails, mid-rails, and toe boards, platforms have anchorage points for safety harnesses. The latter prevents the risk of falls from a height.

Emergency Descent Systems

If a hydraulic or engine failure happens, an emergency descent control that lowers the platform slowly and safely follows. The workers are thus not left stranded at high elevations.

Choosing the Right Rough Terrain Scissor Lift

The best model to choose depends on the work that needs to be done, the place, and the amount of money that is available.

Height and Load Requirements

- Miniatures: 20–30 feet of reach with the lifting of medium weight capacity is possible.

- Giant ones: 50–60 feet of reach with the weight capacity that is high (up to several tons) is available. Pick the one that fits the height of your work and the load you have to carry.

Terrain Type and Jobsite Conditions

- If the ground is muddy or full of rocks, then go for models that have pneumatic tires and outriggers.

- If the site is sloped, then you should pick a lift that has an advanced tilt stability system.

Power Source Selection

- Diesel-powered: Great for heavy works that last long and are conducted out of doors.

- Dual-fuel/hybrid: Highly suitable for a use that is both indoor and outdoor with less emission of pollutants.

Budget and Maintenance Considerations

- Depending on the features, new rough terrain lifts with the capability to handle challenging landscapes can wheel from $40,000 to $90,000.

- For a short-term project, the rental offer can end up being a cheaper option.

- You should think about the environmental impact, maintenance costs, and storing expenses if you are going to have the lift for a long time.

Maintenance of Rough Terrain Scissor Lifts

Regular maintenance exercise is responsible for the safety and reliability of rough terrain scissor lifts. However, since they are in operation in rough areas, they require more attention than standard lifts.

Daily and Weekly Checks

- Observe the capabilities of the tires, hydraulic hoses, and fluid level.

- Emergency stop buttons as well as tilt sensors should be tested.

- Make sure the platform guardrails are secure.

Hydraulic and Engine Maintenance

- Change oil regularly and make sure the fluid levels are good.

- Service the diesel engines by changing filters and lubricating the parts that are in contact with each other.

Tire and Suspension Care

- After every usage on rugged terrain, check the equipment for wear and tear.

- Get new tires immediately when the old ones are worn so that you do not risk the stability of the machine.

Seasonal Adjustments for Outdoor Use

- In winter, use hydraulic fluids that are compatible with the weather conditions.

- In dusty and hot places, the filters need to be cleaned more frequently, and so does the cooling system.

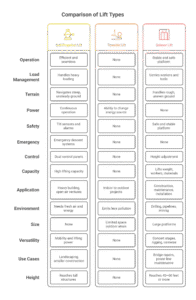

Rough Terrain Scissor Lift vs. Standard Scissor Lift

Firstly, scissor lifts for rough terrain need to be compared with standard ones to be able to appreciate their usefulness.

Key Differences in Design

- Rough Terrain: heavy-duty tires, 4WD, diesel-powered/dual-fuel engines, lifting jacks.

- Standard: These are small compact electric-powered vehicles, equipped with smooth tires that do not cause any harm to an indoor floor.

Performance Comparison

- Rough Terrain: The vehicle depicted here is capable of handling slopes, mud, or any other kind of you might throw at it with a better if load capacity.

- Standard: It is good for a flat and smooth indoor floor with lighter loads besides the mentioned features.

Cost and Fuel Considerations

- Compared with standard ones, rough terrain lifts are more costly and powerful by way of fuel consumption.

- Standard lifts used indoors are cheaper in terms of energy consumption and friendly to the environment.

Which One to Choose for Your Needs?

- If you want to use a lift in your warehouse, factory, and retail environments, a standard one will be the best option for you.

- If you want to do an outdoor construction project, mining, or set up a large-scale event, a rough terrain lift is what you need to go for.

Cost of Rough Terrain Scissor Lifts

The rough terrain scissor lift purchase or rental is a substantial investment. The pricing depends on the model and the specifications.

Purchase Costs and Variations

- Very small models (20–30 ft): $40,000–$60,000.

- Bigger models (50–60 ft): $70,000–$90,000 or more.

Rental Options and Daily Rates

- On a daily basis rental is given from $200 to $500.

- One can rent it on a weekly basis at a rate of $800 to $1,500.

- Monthly rental goes from $2,500 to $4,500.

Long-Term Operational Costs

- The consumption of fuel, the use of hydraulic oil, as well as the tire replacement will all be a part of your annual expenses.

Future Innovations in Rough Terrain Scissor Lifts

The field is changing with the arrival of new technologies that make rough terrain lifts not only safer but also more eco-friendly and cost-effective.

Hybrid and Electric Models for Outdoors

The producers are coming up with battery-powered scissor lifts for the outdoors that can last for longer on a single charge and thus have lower emissions and noise.

Smart Sensors and AI Controls

Advanced robotics (AI) might be involved in future implementations of the stability of the structure, in sending maintenance signals before parts get broken and in allowing GPS to locate the vehicles.

Improved Safety Automation

The coming of automated means load balancing, which may even cause less of a problem in case the person’s presence is not detected by an obstacle sensor, and also remote shutdown may help save the next victim.

Eco-Friendly Materials and Design

Industries are now being encouraged to produce and use more sustainable materials, like those that are lighter and easily recyclable and low-emission engines, in order to help reduce the environmental impact of their sector.

Conclusion

Off-road scissor lifts are the most reliable equipment used in those fields which are basically outdoors and require utmost safety, power, and stability.

These vehicles are equipped with different gears for example four-wheel drives, huge-sized tires, powerful engines, and stabilizers that enable them to be at the top of the game when it comes to working on rough or uneven grounds.

They serve as the backbone in construction, mining, and outdoor maintenance and are also widely used in setting up for huge events as they offer a greater load capacity and less risky working conditions.

Although they are a bit more expensive and need more care, their capacity and multifunctionality make them a better choice for rough job sites and thus an excellent investment.

We are to anticipate the models of the future to be much more intelligent, cleaner, and even safer as a result of technological progressions, therefore, rough terrain scissor lifts will still be the first rescuer of heavy-duty industries.