Essential Parts of Scissor Lift: A Detailed Guide

The scissor lift is one of the most comfortable and handy pieces of equipment that can be found on a construction site, in a factory, or a maintenance department where it is used to raise the workers and the materials to different heights in a fast and safe way. It is also necessary to know the parts of scissor lift for its correct operation, maintenance, and troubleshooting.

This training manual introduces the main components of a scissor lift, i.e. the base, platform, scissor arms, hydraulic system, control unit, and safety rails, etc., with the description of each part and its contribution to the overall operation of the lift. Knowledge of the interaction of these parts will help you to use the machine safely and efficiently.

Base Frame and Chassis

The base frame is the primary structure of a scissor lift that is used to hold the entire machine together and also to provide a firm base. It is quite commonly built from steel or aluminum that has been strengthened to be of a safe weight support for the worker. The chassis pulls the base frame off the main wheels or casters through which the power unit gets mobile and can be driven on various types of ground. Some units have outriggers or stabilizers that can be closed like a fan when you are using the machine on normal ground surfaces with zip safe.

Scissor Mechanism (Scissor Arms)

The scissor mechanism is made of several arms that are joined and arranged in an X shape. These arms are made from strong steel and are the main reason behind the lift’s ability to move up or down. The device moves in response to the power it receives from a hydraulic or electric source, and these things go ahead to the inner panel while the arms expand and straining, the lift gets it here; the said platform thus it is up and down it goes. In addition to ensuring safety and stability at different heights, the number or length of the arms could be for determining different carrying forces by the lift.

Platform (Work Deck)

The platform or work deck is the level surface on a scissor lift where laborers or their materials are put. The aim of the platform is to be solid and safe, it may be provided with safety rails along certain safety arrangements to ward off any drop and secure the workforce. The dimensions and patterns of the platform may be different because of the nature of the model and its use; however, it is always shaped to endure the given carrying capacity.

Hydraulic System

The hydraulic system is the heart of almost all scissor lifts, which is the source of power for them to be raised or lowered. It involves a hydraulic pump, cylinder, hoses, valves, and hydraulic fluid to make a functional unit. The hydraulic pump sends fluid to the cylinder thus giving rise to the pressure that is what makes the piston extension and consequently the scissor arms movement. When the regiment is lifted, there is a relief in the pressure and hence the arms contract bringing the platform down. The hydraulic system is very reliable and capable of producing a great force with just a small effort.

Control System

Controls in the scissor lift movement are safe, and more efficient; this is what the control system offers to the operators. Normally they come up with a joystick or buttons for elevation, lowering, going forward and backward as well as a button for halting the operation immediately in case of an emergency. Besides that, today’s scissor lifts could also incorporate various safety-related elements like tilt sensors, alerting devices, and the system for automatic braking which altogether work towards the safety of the user.

Power Source

Among the different power sources that may be used to drive a scissor lift are electric, hydraulic, diesel, or pneumatic systems. Electric scissor lifts are usually the best option for indoor runs due to the fact that they don’t emit hazardous gases and hardly make any noise. While diesel-driven scissor lifts are mainly for the outdoors and hard work situations. The power source to be used is thus determined by the nature of the task and the place where the work is to be done.

Safety Features

At present, a scissor lift comes packed full of safety gear for the operator and the people surrounding him. Among such are included: the stabilizers and outriggers for more support, the guardrails that surround the platform to aid in fall prevention, the stop buttons for emergencies, tilt sensors and alarms, anti-crush mechanisms, as well as automatic braking systems. To ensure the safe functioning of the lift, these features should be inspected and maintained regularly.

Additional Parts

Besides the main components, a scissor lift is equipped with wheels or casters for moving, rollers or tracks for smoothing the movement, and different sensors and switches for control and monitoring. These components cooperate closely and make the scissor lift safe and reliable in any situation and place.

What are the parts of a scissor lift called?

The key parts of a scissor lift are typically called:

- Base (or chassis/frame)

- Scissor mechanism (scissor arms or legs)

- Platform (work deck or lift table)

- Hydraulic cylinder or electric motor

- Wheels or casters

- Control system (control panel or box)

- Power source (battery, diesel engine, or pneumatic system)

- Safety features (guardrails, emergency stop, tilt sensors, anti-crush mechanisms)

- Valves (down valve, flow control valve)

- Stabilizers or outriggers (optional, for rough terrain models)

Each part works together to provide safe vertical lifting, efficient operation, and secure mobility for personnel and materials.

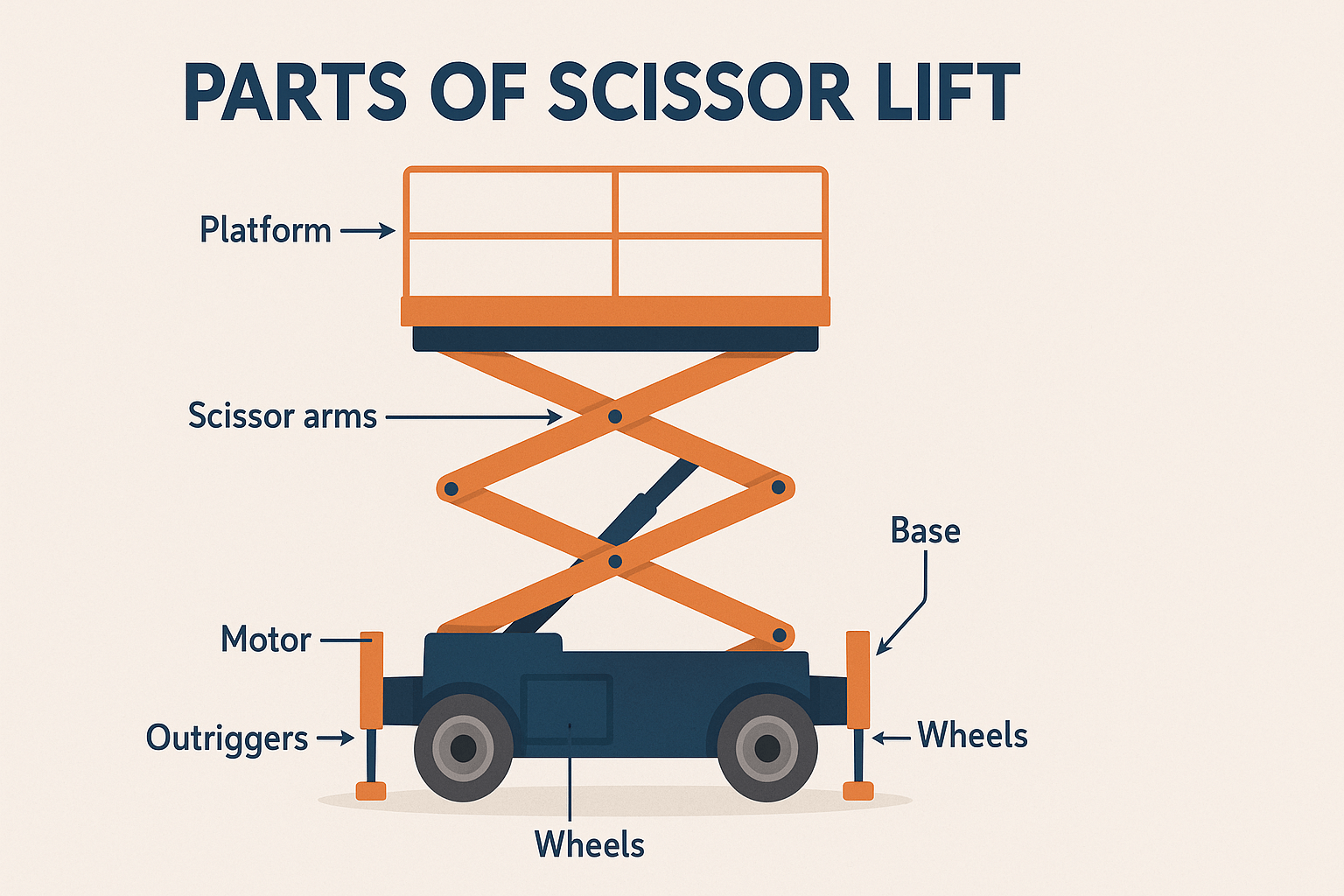

Labeled Diagram of Scissor Lift Parts

- Platform (Work Deck)- The level surface on which people or materials are placed, usually with guardrails for safety.

- Scissor Arms (Scissor Mechanism)- The metal arms in a cross pattern which support the lowering or raising of the platform.

- Hydraulic Cylinder- The cylinder that, through the use of hydraulic fluid pressure, is responsible for the lifting and lowering of the scissor arms.

- Base Frame (Chassis)- The strong and stable frame under the lift which supports the whole lift and encloses the machinery.

- Wheels or Casters- These are the parts connected to the base that make the lift movable.

- Control Panel (Control Console)- The operator’s interface used to move the lift manually with the help of joysticks and buttons.

- Valves and Hydraulic Hoses- They facilitate the implementation of the fluid flow that leads to the lift or lowering of the device.

- Safety Guardrails- These are the rails around the platform that protect the operator.

- Motor and Pump Assembly- This unit energizes the hydraulic system (the electric motor or diesel engine depends on the model).

- Outriggers or Stabilizers- They help the machine to be more stable when, for instance, it is used on a rough surface.

- Emergency Stop Button- This is the button used to stop the lift immediately in case of emergency situations.

List common materials used for each component

Here are common materials used for each main part of a scissor lift:

- Platform (Work Deck): Steel or an aluminum alloy to be both strong and light; and a non-slip coating or a steel grid surface to ensure safety, in some cases.

- Scissor Arms (Scissor Mechanism): Made of high-strength steel or stainless steel, thus being very durable, resistant to impacts, and able to bear heavy loads.

- Hydraulic Cylinder: The body of the cylinder and the piston are made of steel, the piston rods are chrome-plated to make them corrosion resistant and to ensure that they move smoothly; seals are made of synthetic rubber or polyurethane.

- Base Frame (Chassis): The frame is made of heavy-duty steel, which provides the necessary structural strength and the ability to carry the load.

- Wheels or Casters: The tread is made of solid rubber or polyurethane and it is mounted on hubs that are either steel or aluminum; in the case of heavy-duty models, the tires are pneumatic and the rims are made of steel.

- Control Panel (Control Console): The outer shell is made of plastic or fiberglass which makes it durable and resistant to weather; the electrical parts are made of copper and plastic and are insulated, and there are other materials of the electronics grade used as well.

- Valves and Hydraulic Hoses: Valve bodies are made of brass or steel; hydraulic hoses are manufactured from reinforced synthetic rubber or thermoplastic materials to endure the pressure.

- Safety Guardrails: The main material of the tubing is either steel or aluminum, the former providing more strength and the latter being lighter in weight, however, both can be used in combination.

- Motor and Pump Assembly: The main mechanical parts are of steel and cast iron; copper wiring is used for electric motors; the insulation is made of different plastics.

- Outriggers or Stabilizers: The. are predominantly made of steel and are usually covered with some protective coatings to prevent corrosion.

- Emergency Stop Button: It is made of plastic and metal contacts are inside.

These materials are chosen to balance strength, durability, weight, corrosion resistance, and safety requirements in various operational environments.

Final Thoughts

Knowing the parts of a scissor lift should be a must for workers in construction, maintenance, or industries. Every component is extremely important for the safe and efficient performance of the device, starting from the base frame and the scissor mechanism and ending with the hydraulic system and the control panel. The condition of these parts as well as the performance of the entire machine can be maintained through regular inspections and scheduled maintenance. By getting to know the different parts of your scissor lift, and understanding their functions, you will have no problem in operating and maintaining your machine, and it will also give you a professional touch to your work.