Safety in the Heights Understanding Scissor Lift Weight

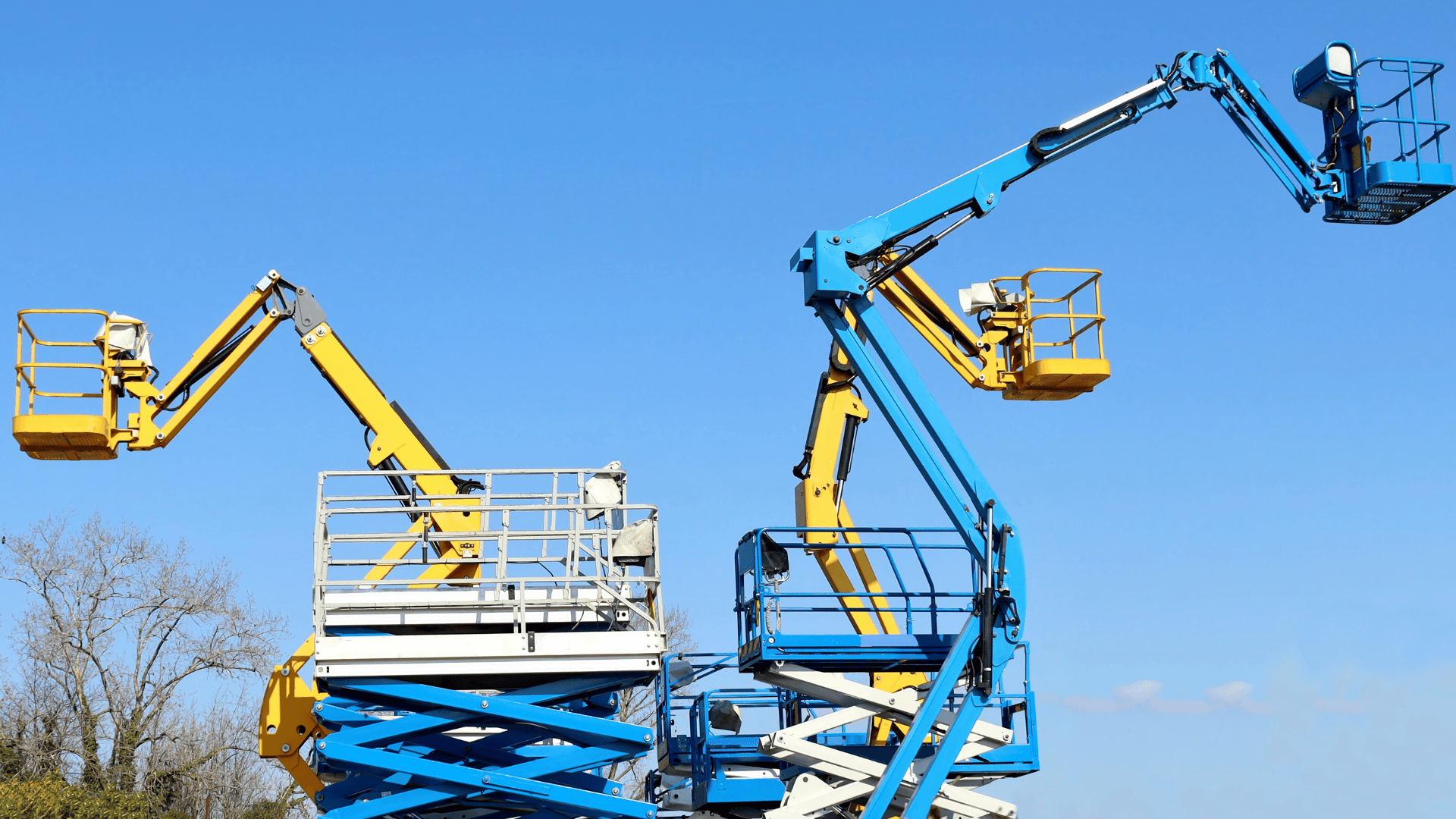

Introduction to Scissor Lifts

Scissor lifts have become a mainstay in various industries, from construction and building maintenance to safety inspections. These versatile platforms provide a safe and efficient way to access elevated work areas, making them indispensable for tasks that require working at height.

If you’ve ever wondered about the true weight of these machines, you’re not alone. Understanding scissor lift weight is crucial for several reasons, including safety, transportation, and operational efficiency. In this post, we’ll explore all the essential aspects of scissor lift weight, offering insights and practical tips for construction workers, building maintenance professionals, and safety inspectors alike.

Understanding Scissor Lift Weight

Factors Influencing Scissor Lift Weight

Weight in scissor lifts can vary greatly depending on a number of variables.

-

- Platform Size Larger platforms naturally weigh more. The size of the platform determines how much material is required for construction, which influences the overall weight.

- Lift Capacity The weight also depends on the lift’s capacity. Heavier-duty lifts designed to carry more weight are built with stronger materials, making them bulkier.

- Materials Used Different scissor lifts are constructed using various materials, each contributing differently to the weight. Steel is a stronger but heavier material, whereas aluminum is lighter.

Weight Distribution

Another important consideration is the weight distribution throughout the scissor lift. Proper weight distribution increases stability, which is necessary for safe operation. Uneven weight can compromise the lift’s stability and increase the risk of an accident.

Impact of Add-Ons

Guardrails, extension decks, and tool trays are examples of additional features that can increase overall weight. While these add-ons enhance functionality, they must also be considered when calculating overall weight.

Average Scissor Lift Weights

Electric Scissor Lifts

Electric scissor lifts are commonly used for indoor tasks. They are relatively lightweight but strong enough for most indoor applications. The average electric scissor lift weighs between 2,000 and 5,000 pounds.

Rough Terrain Scissor Lifts

Designed for outdoor use, rough terrain scissor lifts are built to withstand harsh conditions. These models are more substantial, with weights typically ranging from 6,000 to 10,000 pounds. Their rugged construction helps them navigate uneven surfaces safely.

Indoor Scissor Lifts

While electric scissor lifts are often used indoors, there are also specialized indoor models designed for tighter spaces. These compact lifts usually weigh between 1,500 to 3,000 pounds, making them easier to maneuver in confined areas.

Scissor Lift Sizes and Weight Ranges

|

Scissor Lift Size (Feet) |

Scissor Lift Weight Range (lbs.) |

|---|---|

|

19’ Scissor Lift |

2,700 lbs – 7,000 lbs |

|

26’ Scissor Lift |

7,300 lbs – 13,600 lbs |

|

32’ Scissor Lift |

5,900 lbs – 16,600 lbs |

|

40’ Scissor Lift |

7,300 lbs – 17,000 lbs |

|

50’ Scissor Lift |

11,800 lbs – 17,000 lbs |

Importance of Knowing Scissor Lift Weight

Safety Concerns

One of the most critical reasons for understanding scissor lift weight is safety. Overloading a scissor lift can lead to severe accidents, including tipping over. Knowing the weight helps ensure you’re operating within safe limits.

Regulatory Compliance

Various safety regulations require operators to be aware of their equipment’s weight. Compliance with these regulations isn’t just about avoiding fines; it’s about ensuring a safe working environment for everyone involved.

Logistical Planning

Transporting and handling scissor lifts require careful logistical planning. Knowing the weight helps in selecting the appropriate transport vehicle and ensures that you adhere to weight limits during transportation.

Why Does Scissor Lift Weight Matter?

Understanding the weight of a scissor lift is crucial due to its significant impact on potential productivity. Here are several key aspects to consider:

- Equipment Transportation

- The lighter a scissor lift is, the easier it is to transport. For instance, a single truck can accommodate up to 22 lightweight Hy-Brid lifts, which is about eight more than traditional lifts.

- Load Capacity and Weight Limits

- Heavier scissor lifts, such as rough-terrain models, typically offer higher platform capacities and weight limits, allowing for greater operational flexibility.

- Workers on Project Floor

- A lightweight scissor lift enables more personnel to be present on the working floor without exceeding the maximum load capacity, enhancing workforce efficiency and safety.

How to Find the Weight of Your Scissor Lift

To find out how much your scissor lift weighs, you can always check the equipment spec sheet, which typically includes detailed weight specifications. Companies like scissorlifts.org provide specific information regarding lift weight alongside other equipment specifications.

Additionally, it is essential to read the operation manual before using any type of heavy equipment. Familiarizing yourself with the manual not only helps you understand the lift’s weight but also ensures you are aware of the safety guidelines and operating procedures necessary to maintain a safe working environment.

Always prioritise knowledge of your scissor lift’s specifications for optimal safety and efficiency on the job.

Popular Scissor Lift Models and Manufacturers

While scissor lifts mostly perform the same function, they come in a range of types, models, and sizes. Here are some of the most popular scissor lift manufacturers:

- JLG: JLG manufactures both electric and engine-powered scissor lifts. Their electric models offer zero emissions, quieter operation, and a range of working heights and platform capacities. The engine-powered models are heavier with greater machine widths, providing higher load capacities and larger work areas, making them ideal for more demanding outdoor applications.

- Genie: Known for its electric slab scissor lifts, Genie models excel at navigating tight spaces with impressive maneuverability and minimal noise. Their scissor lifts are particularly useful in indoor settings where space is at a premium, while still maintaining solid performance and reliability.

- Skyjack: Offering a diverse range of lifts—including scissor lifts, forklifts, boom lifts, and telehandlers—Skyjack’s product line boasts versatility to tackle a variety of jobsites, weight capacities, and tasks. Their focus on simplicity and ease of maintenance makes them a popular choice among construction professionals.

- Haulotte: Renowned for their innovation, Haulotte provides a wide array of scissor lifts that cater to both indoor and outdoor operations. Their lifts are designed for robust performance and reliability, often featuring advanced safety features to protect operators.

- Snorkel: Snorkel is known for its commitment to safety and efficiency in their scissor lifts. With options for various working heights and capacities, their lifts are suited for a range of applications, from construction to facility maintenance.

These manufacturers represent just a fraction of the scissor lift market, each contributing unique designs and technologies to meet the diverse needs of different industries.

Lightweight Scissor Lifts

Lightweight scissor lifts, such as the Hy-Brid PS-1930, are designed to have lower floor load pressures and weight capacities. These models typically run on electricity and produce no emissions, making them appropriate for use indoors where air quality is a concern.

Their quieter operation and portability allow for greater ease of navigation in tight spaces. These lifts excel in jobsites with stable, even terrain and are ideal for tasks that require lower heights and can be completed efficiently over shorter periods.

Mid-Range Scissor Lifts

Mid-range scissor lifts, like the Genie GS-2032, strike a balance between weight and versatility. Though they are heavier than lightweight models, they offer the ability to operate effectively in both indoor and outdoor environments.

With increased platform capacities and higher working heights, these lifts are well-suited for a variety of tasks, catering to projects that require greater flexibility in both setting and functionality.

Heavy-Duty Scissor Lifts

Heavy-duty scissor lifts, often exemplified by models like the Skyjack SJ6826/32, are specifically designed for rough terrains. These lifts feature four-wheel drive and high gradeability, allowing them to navigate uneven surfaces with ease.

Utilizing gas as their power source, heavy-duty models provide extended runtimes compared to their electric counterparts.

Despite their greater weight, the enhanced capacity and wider platform of these lifts enable them to accommodate more equipment and personnel, making them invaluable for demanding jobsites.

Scissor Lift Uses

Scissor lifts are vital in various jobsites, particularly for tasks that require working at height or in a vertical direction. They enable construction workers to perform tasks more efficiently and securely than with other less stable equipment, such as ladders. The primary uses of scissor lifts in construction include:

- Carrying and Lifting Workers: Scissor lifts have varying platform capacities that allow them to safely transport personnel to the heights needed for their work, providing a secure platform while they carry out their tasks.

- Lifting and Transporting Materials: These lifts can also be used to efficiently transport materials to workers at different elevations. They facilitate the movement of heavy items, ensuring that materials reach high work areas without the risk of manual carrying accidents.

- Accomplishing Tasks at High Elevations: By transporting both personnel and necessary equipment, scissor lifts significantly enhance safety and accessibility for completing construction tasks at high altitudes, which may otherwise be difficult to reach.

The range of scissor lifts available offers great versatility for industry applications, extending beyond construction. With options tailored for indoor and outdoor use across various terrains, users can find the right lift for virtually any task.

Additional Uses of Scissor Lifts

In addition to construction, scissor lifts can be employed in several other industries and applications:

- Landscaping: Aerial lifts are invaluable for landscapers, allowing them to reach foliage at varying heights for tasks such as pruning tall trees, installing outdoor lighting, and safely transporting heavy equipment to different elevation points without risk of injury.

- Business: Various businesses rely on scissor lifts for a multitude of tasks, including changing lights, hanging signs and banners, retrieving and storing equipment and supplies, performing repairs, and accessing utilities. Their versatility ensures that maintenance and operational tasks can be completed more efficiently and safely.

- Warehouses: Scissor lifts significantly enhance warehouse operations, enabling workers to reach high shelves for picking and sorting inventory. They also facilitate the transportation of heavy goods to various heights, improving productivity and efficiency in stock management.

These applications demonstrate the flexibility and importance of scissor lifts across a range of industries.

How to Choose a Scissor Lift

Many factors matter when choosing the right scissor lift for your jobsite. Some of the most important ones to consider are:

- Project Budget: The cost of renting a scissor lift can range greatly depending on the machine you choose, from about $102 to $379 per day. The rate also changes if you’re looking for a daily, weekly, or monthly rental. Generally, the greater the height and capacity of the machine, the more expensive it will be.

- Scope of Work and Site Conditions: Are you working on rough terrain or even, flat ground? Indoors or outdoors? Lightweight, electric lifts work better on stable ground, indoors, and in tight spaces for shorter durations. For uneven terrain, outdoor use, and longer runtimes, you’ll likely need a diesel-powered machine.

- Platform Size and Weight Requirements: The scissor lift you choose should be designed to bear the weights required of your job. If you have to transport a lot of personnel or heavy equipment, you’ll likely need a heavy-duty machine; a one- or two-person job with lightweight equipment doesn’t need as much capacity or platform width.

- Lift Height and Stability: Similarly, you have to account for the minimum and maximum working heights you need, so that you get a machine with adequate vertical reach to accomplish your task. By carefully considering these factors, you can ensure that you select the most suitable scissor lift for your specific project requirements.

Handling and Transporting Scissor Lifts

Loading and Unloading

Proper loading and unloading techniques are essential for safe scissor lift handling. Always use the manufacturer’s recommended loading equipment to avoid accidents. Ensure the lift is securely fastened during transport to prevent shifting.

Securing for Transport

Securing a scissor lift for transport involves more than just strapping it down. Use heavy-duty chains or straps to anchor the lift, and double-check all connections before hitting the road. Inadequately secured lifts can become hazardous projectiles in case of sudden stops or accidents.

Unloading Procedures

When unloading, follow the same safety protocols you used for loading. Ensure the area around the lift is clear and that you have adequate space to maneuver. Take it slow and steady—rushing can lead to mishaps.

Conclusion

Understanding scissor lift weight is more than just a technical detail—it’s a crucial aspect that impacts safety, compliance, and logistics. By being informed about the various factors contributing to scissor lift weight, you can make better decisions, operate more safely, and ensure smoother transport and handling.

We hope this guide has provided valuable insights into the world of scissor lifts. For more detailed information and expert advice, don’t hesitate to explore our website or contact our team. Your safety and efficiency are always our top priorities.

Take the Next Step

For those looking to explore more about scissor lifts, lift handling, and industry best practices, we invite you to sign up for our newsletter or schedule a consultation with our experts. Stay informed, stay safe, and elevate your operations to new heights!