Scissor Lifts for Facility Management: A Complete Guide

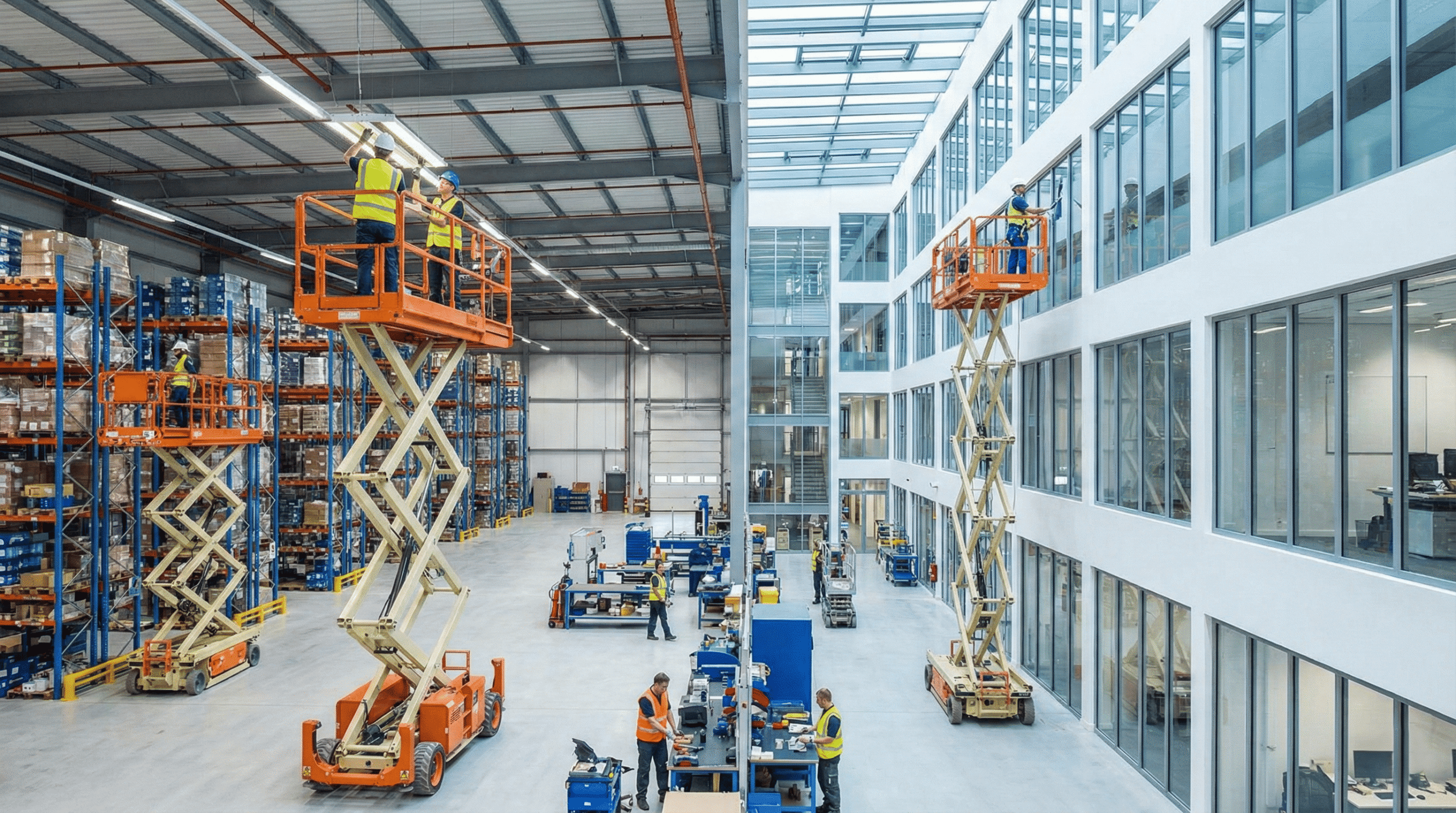

Accurate, safe, and technologically advanced are the key factors in effective of the scissor lifts for facility management that are going to be essential in 2026. The vertical challenges can be managed easily with the help of scissor lifts in facility management no matter if you are running a warehouse packed with technology or a corporate headquarters.

These machines not only provide a stable and high-capacity solution for accessing elevated areas, but also, they are far beyond ladders’ limitations. This paper discusses how your operations could be made more efficient and your personnel safer at work if you installed the right aerial equipment.

Scissor Lifts for Facility Management – Strategical Role:

The present day buildings carry the concept of preventive maintenance and quick repairs to a different level with the help of scissor lifts for facility management. Scaffolding, for example, requires much time for its assembly and, therefore, a scissor lift is portable and can be used immediately. Facility managers who are in the constant struggle of a tight schedule and need for thorough building care can only appreciate such an advantage.

- Vertical Versatility: The lifts provide easy access to the HVAC systems, lighting fixtures, and fire alarms, which are all quite common for the ceiling installation.

- Increased Capacity: Technically, the majority of the models provide capability for two workers plus the heavy tool kits, thus drastically the task of complex installation becomes less time consuming by pairing two people.

- Safety Made Integral to the Design: Some of the standard features are shown to be tilt sensors, emergency lowering systems, and high-strength guardrails which all are 2026 safety compliant.

Tips on Selecting Scissor Lifts for Facility Management

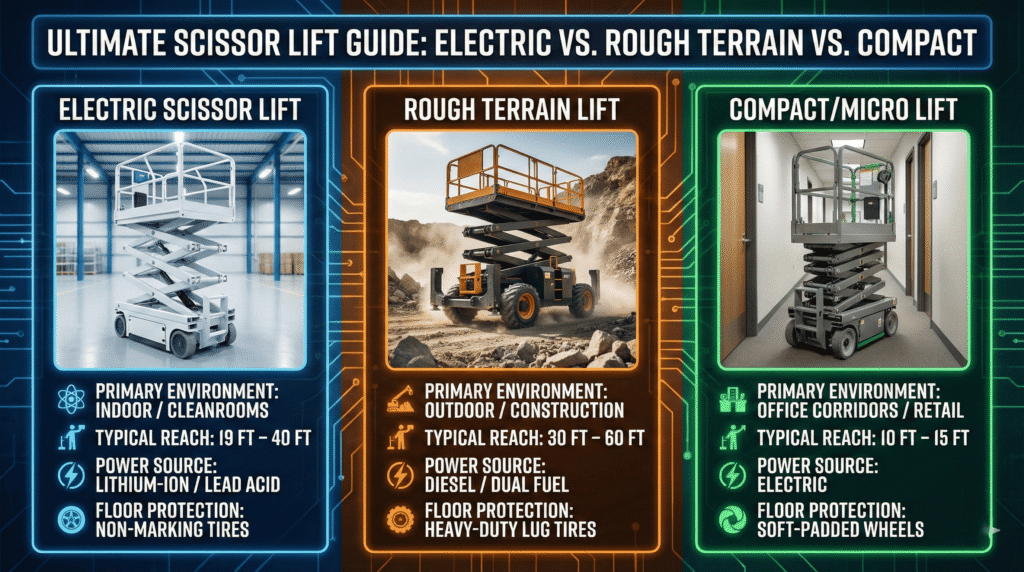

Since modern buildings are quite different means that there is a question if it is possible for the apparatus to be “one size fits all”. It is crucial to establish which scissor lifts for facility management are the most appropriate in order to pick the right ones by taking into account the feature of the environment. Generally speaking, inside office space, the baseline would be electric types with tires that don’t leave marks whereas the outer environment is structurally quite different and it is only natural that the power and diesel engine of the lift work decide the level.

- Electric Machines: Offer exceptional indoor functionality with features that ensure silent operation and total absence of emissions which are very important for air quality in closed spaces.

- Rough Terrain Vehicles: With the addition of outriggers and the trait of four-wheel driving, these are perfectly suited for the situation of getting repairs done to the exterior facilities on the unpaved areas of ground.

- Compact Models: The narrow-aisle scissor lifts are promoted as a product, which can go through standards doorways and even reach tight storage rows.

Comparison Between Models for The Facilities Tasks

| Feature | Electric Scissor Lift | Rough Terrain Lift | Compact/Micro Lift |

| Primary Environment | Indoor / Cleanrooms | Outdoor / Construction | Office Corridors / Retail |

| Typical Reach | 19 ft – 40 ft | 30 ft – 60 ft | 10 ft – 15 ft |

| Power Source | Lithium-ion / Lead Acid | Diesel / Dual Fuel | Electric |

| Floor Protection | Non-marking Tires | Heavy-duty Lug Tires | Soft-padded Wheels |

Using Scissor Lifts for Facility Management to Boost Your Efficiency

Scissor lifts for facility management are considered hardly more than practical pieces of equipment that get you up and down easily but in fact, their integration in your operational routine can result in the optimization of your entire work force. Capacities of working at height related to safety seem to be the most obvious impacts but the product time decrease and the cost reduction related to productivity losses due to the work stoppages are the factors scarcely noticed yet still tangible to the watchful eye.

- Work Speed: It is possible to move around the fixtures in the lift without going out by driving a full-height lift (on level surfaces).

- Ergonomics: Using a safe platform on the level that is most suited for the activity means considerably less physical stress and weariness which are usually the effects of ladder work.

- Maintenance Forecasting: The lift that is IoT (Internet of Things) connected is the feature of a modern one enabling it to give the facility maintenance staff an early service warning before the fault occurs.

Upkeep of Scissor Lifts and Safety Rules

The use of scissor lifts for facility management doesn’t only provide endless possibilities of work at height but also comes with the burden of maintaining the machines in top condition. Consistent upkeep is one of the requirements allowing enjoying the benefits of scissor lifts constantly and maximally. Furthermore, maintenance helps with the equipment lifespan extension and at the same time keeps the entire facility in line with the international safety codes such as those from OSHA and ANSI.

- Inspection daily: Before starting, the operators should walk around the scissor lift and check visually if there are any hydraulic leaks, tire tread, and battery power.

- Service by Professionals: You should plan a deep mechanical inspection half-yearly checking scissor arms’ structural strength and pivot pins.

- Certification of Operators: Training of all staff on the exact model being used is essential so as to prevent accidents resulting from the mishandling of equipment.

Green Solutions: The Move Towards Electric Lifts

The push for the net-zero target has raised the altar of the demand for 2026 scissor lifts for facility management that are environmentally friendly. At the moment, the facility managers who are most at the forefront and have visionary thinking about the future are the ones that mainly use electric and hybrid models and to them, reducing the carbon footprint is simply unacceptable even if it were to mean compromising on loading power and reliability of the equipment.

- Work Without Emissions: Thanks to the electric lifts the maintenance indoors can be scheduled round the clock in the absence of any ventilation system requirements to get rid of exhaust gases.

- Durable Batteries: Currently, with the introduction of new lithium-ion technology, the duty cycles have been concluded to be longer such that even an entire shift of work can be accommodated with one charge only.

- Noise Reduction: Since the motors that are installed in these lifts are quite quiet, such devices have become very appropriate to be used in hospitals, schools, and libraries where the requirement for keeping the noise level at a minimum is high.

Experts’ Answers On Scissor Lifts For Facility Management

What is the most usual height for indoor scissor lifts for facility management?

Generally, it is a matter of preference of the facility manager and also budget by whether to buy a 19-foot or 26-foot model. This is mainly dictated by the fact that such ceilings heights are the typical ones found in the commercial buildings and also by the fact that at these heights, the scissor lift can still be of a size that it fits through any office door with ease.

Can I operate an outdoor scissor lift inside the facility?

Yes, it is a possibility given that the lift is dual-fuel or electric. Nevertheless, as a matter of principle, never use diesel powered rough terrain lifts for indoor work since carbon monoxide poisoning hazard is not the only reason but also there is a risk of damage to floor coverings due to the heavy tires.

In general, what is the maximum load which can be supported by a facility scissor lift?

Most of time, the average electric lift can carry a load of 500-1000 lbs which is sufficient for two persons and their equipment if the equipment is such to require to always have replacement ballasts, tools or paints.

How does a scissor lift improve the safety compared to a ladder?

The main thing that a scissor provides is a fully enclosed platform which significantly lowers the chances of falling. Also, it removes the necessity for “three-point contact” a sort of system of ladder usage whereby the user has to be in contact with the ladder with two hands and a foot or one hand and two feet thus inherently disallowing the use of both hands freely for the task at hand.

Do I have to get a specific kind of insurance for operating scissor lifts for facility management?

Generally, the operation of aerial lifts is covered by your general liability and workers’ compensation insurance so long as the operators have received the proper training and certification based on the latest local requirement.

What is the battery life of an electric scissor lift?

The answer for a modern electric lift is 6 to 8 hours of intermittent use capability on one charge on average. Thus, overnight charging is the norm to make sure the lift is ready for the next day’s maintenance schedule.

Should I go for purchasing a scissor lift or renting one for a single institution?

Introducing a buying decision is recommended if maintenance works that involve high reach are done more than once a week whereas the case of renting would better describe situations when maintenance such as window cleaning that only occurs yearly or even the hanging of the seasonal banner is trials-type work and in need of the least possible investment in the tool side.