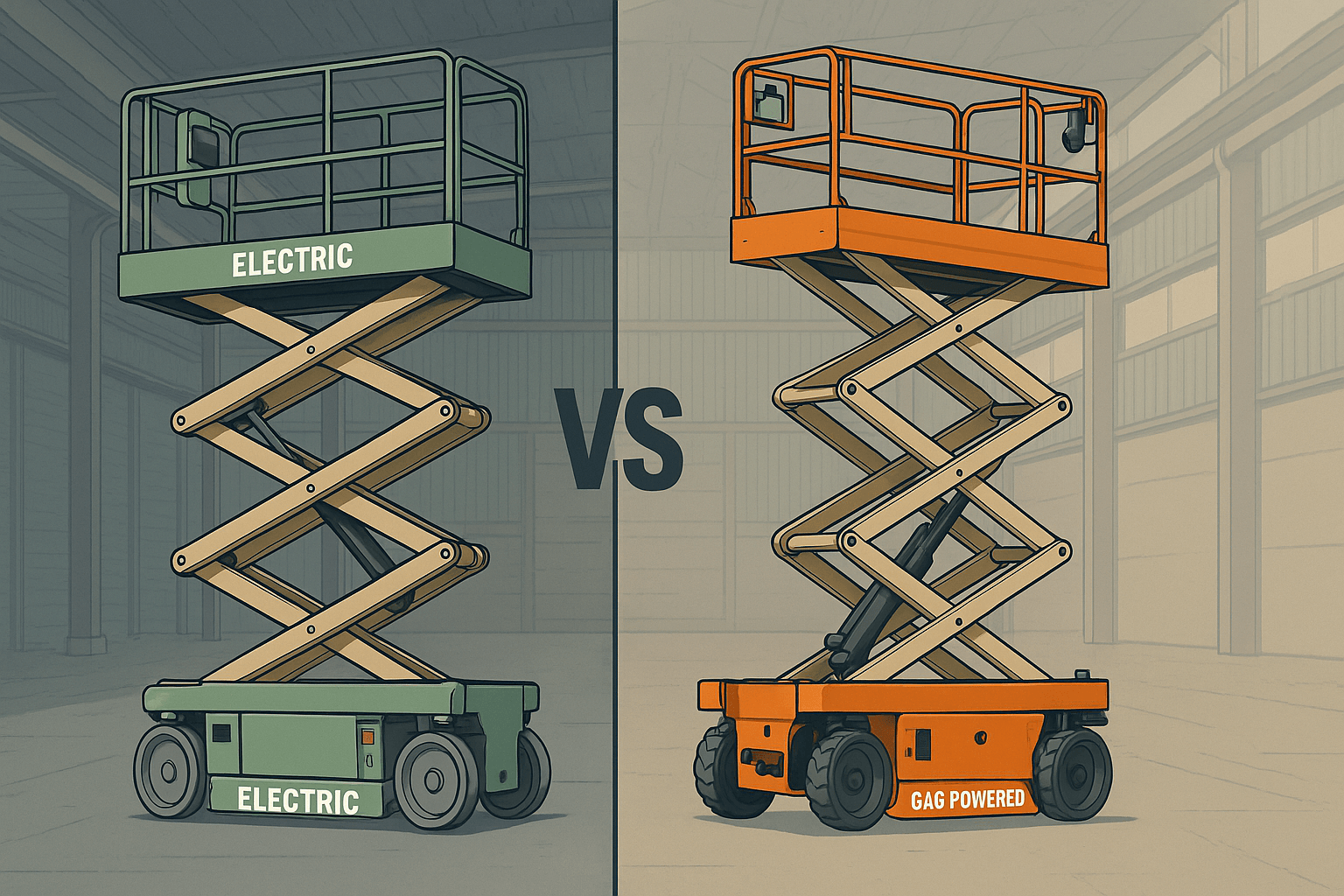

Electric vs Diesel Scissor Lift Comparison: Benefits, Costs, and Applications

The choice between an electric and a diesel scissor lift can have a dramatic effect on your project’s success, efficiency, and, the bottom line. Depending on the characteristics of your project, the good scissor lift can be different, and to make such a decision an understanding of the matter is of vital importance.

Electric scissor lifts are great for indoor use as they do not emit any pollution and are noiseless, while diesel lifts are used in outdoor conditions mainly because of the great power and high adaptation to rough terrains that they gives comparison, profitability, and the best choice of a unit for the required project.

Key Takeaways:

- Electric scissor lifts have the edge over their indoor counterparts thanks to their zero emissions, silent operation, and reduced maintenance costs; hence they are the most suitable for retail shops and manufacturing facilities.

- Diesel-powered scissor lifts, which are the weapons of outdoor construction, and off-road, are unmatched in the power of the engines and the tasks, they handle.

- In addition, depending on the initial cost, electric models appear to be cheaper in the long run – they have lower operational costs, but a higher launch price, while diesel models may have high expenses and the need for a deposit, but they have more chances for further use.

- Environmental conditions always play a key role in it that the electric ones are fully compliant with strict emissions and are used indoors. On the other hand, diesel is always chosen for outdoor logistics and rural regions.

- Electric and diesel are differentiated by a company according to their demands, for example, they may include the environment in which they work, the capacity they can handle, the ground conditions are, the duration of use, among others.

Electric Scissor Lift: Features and Capabilities

Key Performance Characteristics

Electric scissor lifts are synonymous with their extraordinary excellence in indoor operations. The electric motor, which is also silent, provides a means to carry out noise-free work in places such as hospitals, offices, and retail premises. They offer fine control as well as the possibility of smooth running and as a result, they enable the operators to efficiently perform their tasks in narrow areas.

The electric drive zero-emission feature is responsible for the green image that the manufacturer is projecting thus protecting not only the workers but also in a space with little air change such as a warehouse, the operation causes minimal or no disturbance because of the pollution-free nature of the electric scissor lift. Besides its non-marking tires and small size, the electric indoor warehouse lift is also capable of passing through tight aisles and doors without leaving a trace or causing any damage to flooring.

Battery System and Management

The motorized scissor lift storage is the vehicle’s best feature. Newer electric scissor lifts are easier to use and offer more power. A scissor lift may include a high-cycle battery for all-day power. Given use and lifting circumstances, the battery should last 6-8 hours on a single charge.

Power consumption and battery life are optimized via smart battery management technologies. Most electric scissor lifts include regenerative braking systems that return energy to the battery during descent. This high-tech feature allows full machine utilization, minimizes energy costs, and decreases the environmental effect of the usual operation.

Battery charging is easy using a home power point. Electric forklift models usually include in-built charging mechanisms that switch off once the battery is completely charged, avoiding overcharge and extending battery life. Use a regular charging schedule during non-working hours to keep the lift ready.

💡 Key Takeaway: For continuous operation with noiseless operation, no emissions, and remarkable battery power, electric scissor lifts are ideal. They are best for interior spaces that value eco-friendly, quiet, and efficient aerial work platforms.

Diesel Scissor Lift: Power and Performance

Diesel scissor lifts can be installed at very many places owing to their robust nature and a power range that is very wide. They are very versatile and are mostly used in extensive industrial and construction applications that are highly demanding and also require very high power outputs. Their durability and design allow them to be put into almost all kinds of activities.

Operational Capabilities

Diesel engines, the most stable and continuous power source, allow these lifts to lift more than electric ones. Based on model, the most common diesel lift may attain the lift with machine-to-machine rates from 1500 to 4000. This amazing lifting power makes these devices popular in construction, where large goods and personnel must be lifted.

Diesel-powered access platforms operate longer and don’t require refilling. Unlike electric versions, which must stop to charge batteries, these machines may be run nonstop and refueled instantaneously, maximizing productivity on time-bound jobs. However, electric versions require frequent charging. Therefore, diesel-powered ones will function similarly and not require a break till refueled.

The Movement Abilities

Scissor lifts using diesel fuel have a particularly big role in the most various landscapes. They are notable for their robust design and powerful engines which make the rough terrain no obstacle for them.

These machines typically have:

- features of the 4WD system

- a lot of distance from the ground

- strong tires that can be used on all types of surfaces

- an even stronger control of the grip / extra grip control system

This diesel-operated type of lift is known for its great torque. It allows them to climb steep hills and uneven surfaces comfortably.

They can be a vital source of construction site equipment for various outdoor activities including mining, where rough surfaces may be encountered and a typical lift may not match the off-road use requirements.

Now, the capability to operate in different weather conditions is additionally a strong point of this kind of lift. A diesel scissor lift can go on with the work in rainy, muddy, or gravel concrete areas without any change in the performance. In spite of the weather conditions, the lift will be reliable and will work without any disturbances.

💡 Key Takeaway: Diesel scissor lifts can perform the best in high-end applications as they possess a higher lifting capacity and great skills for the terrain; the feature makes for a perfect solution for high-duty outdoor locations and extra-heavy construction projects.

Ideal Applications and Usage Scenarios

Indoor Applications

Electric scissors lifts are the best for indoor space which can be controlled especially in generating little or no noise as well as exhaust gases. With no emissions, these tools can be utilized indoors in various settings such as warehouses, manufacturing facilities, and retail spaces. They are an environmentally friendly solution for those indoor spaces working on HVAC, air conditioning installations, and electrical work where air quality is of great importance.

The easy operation and minimal noise of electric lifts guarantee that the businesses can go on without being disturbed. They are extremely efficient for maintenance of the occupied buildings and no discomfort is caused to the occupants during the work time.

Outdoor Applications

Outdoor diesel scissor lifts are hard to match due to construction sector noise pollution. They conduct outside DIY, particularly in unpowered structures. Diesel lifts are essential for construction. They thrive in unexpected terrain and environments because they are accustomed to them.

Their great lifting capability and lengthy runtime make them perfect for lengthier outdoor maintenance activities. In isolated places with little electric charging, diesel lifts are ideal. They also work effectively in high heat and cold.

Diesel scissor lifts are used in construction for external building maintenance, façade work, and larger-than-life installations. Construction workers lift large weights continuously. The most consistent performance and ability to run without pausing and carry bigger weights are needed for challenging jobs.

💡 Key Takeaway: It is recommended that you use electric scissor lifts indoors and in places with controlled conditions and diesel lifts outdoors, most suitable, especially in the construction industry where power and durability are the most necessary.

Thoughts To Share

Selecting electric or diesel scissor lifts requires considering its intended use, indoor or outdoor placement, and long-term running costs. Electric scissor lifts are quieter and emission-free, making them perfect for interior usage. Diesel scissor lifts are excellent for outside usage owing to their power and rough terrain capability. Your choice should match project requirements.

Choose an electric scissor lift for retail or industry interiors. Building sites and rural locations with sporadic electricity benefit from diesel-powered access platforms. Consider fuel, maintenance, and environmental costs while making selections. Discuss your needs with reliable rental companies. Choose the right equipment for your project to boost efficiency and investment returns.

FAQs

What is the average battery life of an electric scissor lift?

Under normal operating conditions, the battery of an electric scissor lift can run for 8-10 hours on a single charge. With the right maintenance and battery regeneration techniques, the battery can perform at its best for 4-5 years before it needs to be replaced.

Can scissor lifts be used in indoors or outdoor applications with great limitations?

Truly, diesel scissor lifts can be used in partially enclosed spaces, but it’s not practical due to both exhaust emissions and noise levels. Hence, ventilate the working area and think of the option of using electric scissor lifts for semi-enclosed spaces as a bare minimum to comply with the health and safety standards.

How is vehicle performance affected by weather between electric and diesels scissor lifts?

It has been observed that the diesel scissor lift perform better everywhere, regardless of the bad weather. In the weather of the electric model, the battery performance would suffer seriously while a diesel lift would still be in top form. A new trend that is storming the market in the last few years is to find electric lifts being designed with all-weather features.

What are the differences in the noise levels of the electric and diesel scissor lifts?

Mid-way through operating, electric scissor lifts generate a sound that does not exceed 60-65 decibels which is normally equivalent to a conversation between people. Scissor lifts using diesel engines are the worst because they create 85-95 decibels which is no different from the noise of heavy traffic. Obvious from the above, electric-powered models are the absolute first choice in a noise-averse situation.

Did the business just launch loads?

Hybrid scissor lifts with electric and diesel operation are possible. These machines are versatile and can be used both indoors and outdoors as per their power source or that of the environment they are being used. One distinct feature of these lifts is the fact that they are power exchangeable, that is, they can be powered with electric power.

The usual maximum weight capacity of electric and diesel scissor lifts is of what ratio?

Diesel lift tables generally have larger maximum load capacities, usually from 1,500 to 4,000 pounds. Electric models are usually able to lift weights from approximately 500 to 2,500 pounds. However, a number of highly efficient electric versions, even though being quite low in their emissions, are not only able to provide the power but also able to achieve, and sometimes surpass, the diesel capacities.