Scissor lifts, an integral part of the material handling industry, offer a versatile solution for various lifting tasks. These platforms are pivotal in providing a secure and stable work surface at elevated heights, thereby enhancing safety and efficiency in operations. Scissor lifts are uniquely designed to elevate personnel, tools, and materials, making them indispensable in construction, manufacturing, and retail environments. They derive their name from the scissor-like mechanism that allows the platform to ascend vertically. This document will explore the diverse uses, critical parts, and various types of scissor lifts, shedding light on their significance and functionality in different sectors.

What is a Scissor Lift?

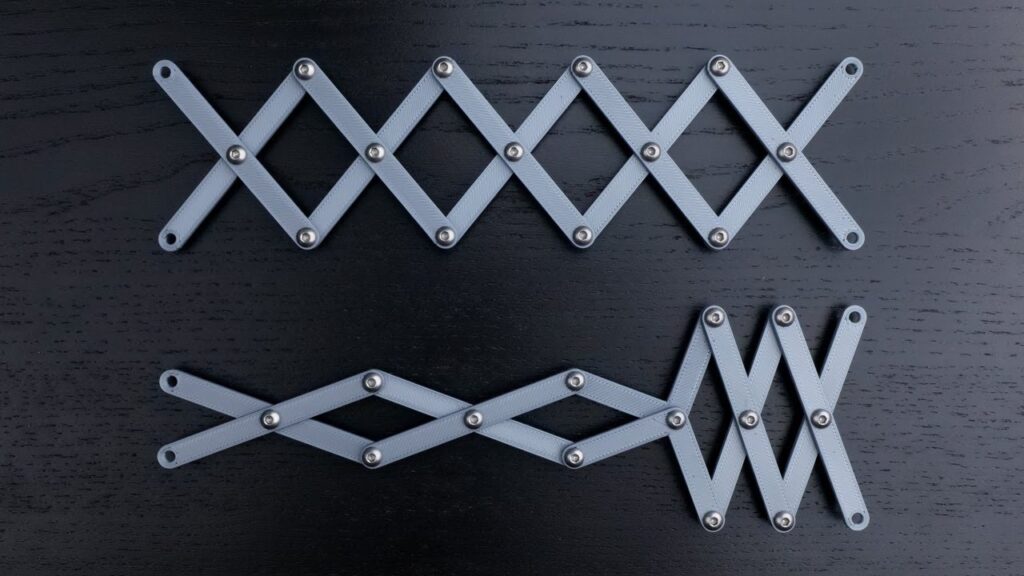

A scissor lift is a motorized vehicle with a railed platform that can be elevated straight up—thanks to its crisscrossing metal supports, resembling a pair of scissors. These powerful machines are designed to safely lift personnel and equipment, making them indispensable in construction, maintenance, and even in the entertainment industry for setting up large-scale events.

Uses of Scissor Lifts

Scissor lifts have become an essential piece of equipment in multiple industries due to their various applications. Some common uses of scissor lifts include:

- Construction and Maintenance: Scissor lifts provide a stable platform for workers and their tools to reach elevated heights, making them ideal for construction and maintenance tasks such as painting, wiring, and roofing.

- Warehouse and Retail Operations: In warehouses and retail environments, scissor lifts are used to transport goods from high shelves or assist in inventory management.

- Film and Entertainment Industry: Scissor lifts are commonly used in the film and entertainment industry for lighting and camera setup, as well as creating elevated platforms for performances.

- Agriculture: Farmers and agricultural workers use scissor lifts to reach high crops or perform maintenance on farm equipment.

- Emergency Services: In emergency situations, such as rescuing people from tall buildings or performing repairs on electrical poles, scissor lifts provide a safe and stable platform for operations.

Different Scissor Lift Parts and Their Functions

The functionality and safety of scissor lifts are reliant on several key parts, each playing a crucial role in its operation. The base provides stability and houses the lift’s motor and hydraulic or pneumatic pump, which powers the ascent and descent of the platform. The scissor arms, made from heavy-duty steel, are central to the lift mechanism, expanding and collapsing to raise or lower the platform. Additionally, the platform itself is designed for load capacity and space, ensuring that workers and materials are safely elevated.

1. Platform

The platform is the heart of the scissor lift, serving as the stage for workers and their tools. This is where tasks are performed, from electrical installations to inventory stocking. Safety railings encapsulate the platform, ensuring worker safety at elevated heights.

2. Scissor Mechanism

The scissor mechanism is what gives this equipment its name and its lift. Composed of cross-braced supports, it extends and collapses, allowing the platform to rise and descend smoothly.

3. Hydraulic System

Hydraulic scissor lifts utilize fluid power to perform lifting operations. The hydraulic system converts mechanical power into hydraulic energy, enabling the lift to handle heavy loads with ease.

4. Control Panel

Located on the platform, the control panel is the command center, allowing operators to maneuver the lift’s movements. It includes controls for raising and lowering the platform and moving the equipment, if mobile.

5. Power Source

Scissor lifts can be powered by hydraulic systems, diesel engines, electric batteries, or pneumatically. The choice of power source often depends on the lift’s intended use and the work environment.

Learn More: TOP 10 SAFETY PROTOCOLS: ELEVATING SAFETY WHEN OPTING FOR SCISSOR LIFT HIRE

Types of Scissor Lifts Based on Applications

Scissor lifts can be categorized into several types based on their specific applications, each designed to meet the unique demands of different work environments. Electric Scissor Lifts are preferred for indoor use or in environments where noise and emissions must be kept to a minimum, such as schools or hospitals. They are known for their quiet operation and smaller carbon footprint. Rough Terrain Scissor Lifts are built with more robust tires and enhanced power, making them suitable for outdoor work sites with uneven surfaces. These lifts often feature four-wheel drive and significant weight capacities to handle tougher jobs and more challenging terrains.

1. Hydraulic Scissor Lifts

Ideal for indoor use or smooth surfaces, hydraulic lifts are known for their smooth movement and ability to carry heavy loads. They are commonly used in manufacturing and industrial settings.

2. Diesel Scissor Lifts

These are suited for outdoor tasks where more lifting power is required. Diesel engines provide the robust performance needed for rough terrains, making them a go-to for construction sites.

3. Electric Scissor Lifts

Electric models are environmentally friendly and operate quietly, making them perfect for indoor applications and areas where noise and emissions are a concern, such as shopping malls and office buildings.

4. Rough Terrain Scissor Lifts

Designed with stronger tires and four-wheel drive capabilities, these lifts can navigate uneven outdoor landscapes. They are essential in construction and landscaping projects.

5. Pneumatic Scissor Lifts

Using air pressure as their power source, pneumatic lifts are ideal for environments where electricity or emissions could pose a risk, such as in chemical plants or food processing facilities.

Learn More: MOVEABLE SCISSOR LIFT: DEFINITION, SPECIFICATIONS, USES & ADVANTAGES

Conclusion

Scissor lifts are a testament to engineering ingenuity, providing safe and efficient access to heights that would otherwise be unreachable. Whether it’s a hydraulic lift in a warehouse, a diesel-powered model on a construction site, or an electric scissor lift in a shopping center, these machines play a crucial role in daily operations across various industries. By understanding the types, parts, and uses of scissor lifts, industry professionals can select the right lift for their specific needs, ensuring productivity and safety in their projects.

For construction industry professionals, warehouse and logistics personnel, and maintenance teams, scissor lifts are not just tools but partners in progress, enabling them to achieve new heights of success in their respective fields.