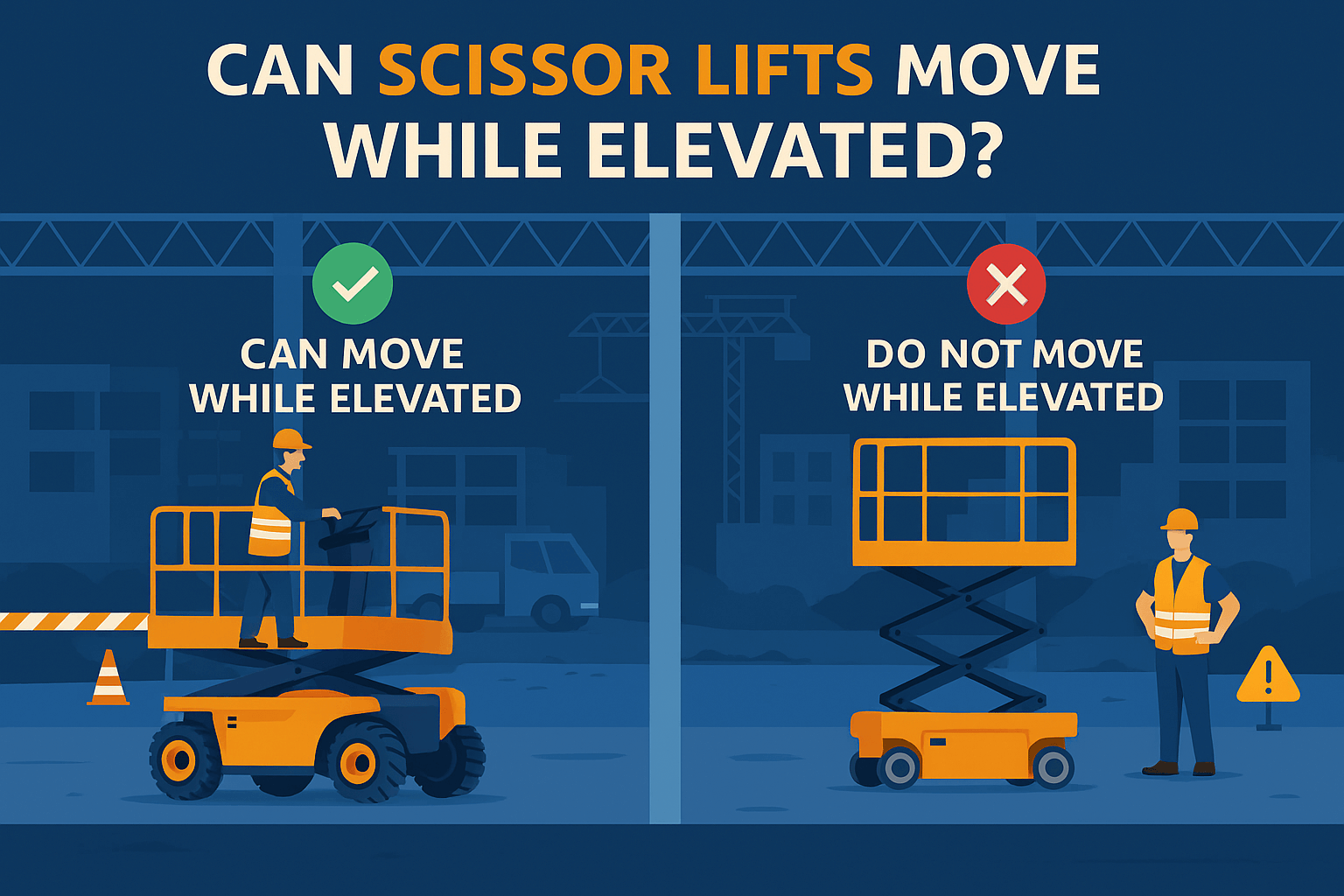

A scissor lift can move while elevated under limited and controlled conditions, but doing so introduces major safety risks and is only permitted if the manufacturer explicitly allows it. The key is understanding the lift type, operating environment, and safety protocols required to prevent tip-overs and accidents.

When Movement Is Allowed

Some self-propelled scissor lifts are designed to drive while slightly raised—usually within a restricted height limit (typically 1–2 meters). These lifts feature safety systems such as tilt sensors, load sensors, and pothole protection to maintain stability during movement. However, push-around and electric models are never safe to move when elevated, as they have no powered drive system and become unstable if shifted while extended.

Major Risks

Driving a scissor lift while elevated raises the platform’s center of gravity, dramatically increasing the likelihood of tipping. Common hazards include:

- Tip-overs due to uneven ground or slopes

- Crushing injuries from overhead obstacles or collisions

- Unintended motion or loss of balance on windy or unstable surfaces

- Reduced control and maneuverability, especially when carrying heavy loads.

Even at modest heights, a small bump or slope can cause catastrophic balance loss. That is why most safety authorities, including OSHA and ANSI, strongly advise against moving scissor lifts while raised unless designed specifically for it.

Safety Guidelines

If a manufacturer permits slow elevated movement, operators must:

- Keep the platform within the manufacturer’s specified travel height limit

- Operate only on flat, level, and debris-free surfaces

- Maintain slow, deliberate motion

- Ensure no overhead hazards or nearby power lines

- Wear PPE such as a harness attached to the anchor point

- Follow MEWP (Mobile Elevated Work Platform) training and certification standards before operation.

Best Practice

The safest approach is always to lower the lift before repositioning it. Lowering may take a bit more time, but it eliminates nearly all tip-over risk and ensures stable operation. Unless the equipment is specifically rated for elevated travel, moving a raised scissor lift is prohibited by OSHA and manufacturer guidance.

In short, while certain models can technically move while elevated, the safest and legally compliant procedure is to lower the platform before moving—preventing accidents, protecting workers, and staying within safety regulations.

Which scissor lift models allow driving while elevated

Several modern self-propelled scissor lift models are specifically designed to allow limited driving while elevated. These units include safety mechanisms like tilt sensors, load limiters, automatic pothole protection, and proportional controls that enable controlled motion within defined height ranges. Below are well-known models from major manufacturers that support elevated drive functions.

Key Takeaways

- Only self-propelled scissor lifts (electric or rough-terrain) with manufacturer-specified elevated drive limits permit movement while raised.

- Driving height is usually restricted to a few meters below full extension, often defined by internal sensors or control lockouts.

- Push-around, hydraulic, or manually positioned units (common in maintenance tasks) must never be moved when the platform is elevated.

Operating Guidance

Operators should always consult the specific model’s operator manual for the maximum allowable drive height and surface requirements. Even with these features, movement must be slow, deliberate, and only on level ground to maintain stability and compliance with OSHA and ANSI standards.

In short, select models from Genie, JLG, Haulotte, Dingli, and Zoomlion include limited elevated drive functions—yet only when operated strictly within their engineered parameters and certified stability zones.

Which safety standards regulate driving elevated scissor lifts

Driving elevated scissor lifts is strictly governed by OSHA, ANSI, and ISO safety standards that define when and how limited elevated movement is permitted. These standards address design, operation, training, and environmental safety factors to prevent tip-overs, collisions, and falls.

OSHA Regulations

- 29 CFR §1926.451 – Scaffolds:

OSHA classifies scissor lifts as mobile supported scaffolds, not aerial lifts. This section covers platform stability, load capacity, and surface conditions required for safe operation while elevated. - 29 CFR §1926.452(w) – Mobile Scaffold Requirements:

Operators must ensure lifts are used only on firm, level surfaces and are not moved with workers on an elevated platform unless approved by the manufacturer. - §1926.454 – Operator Training:

Employers must provide safety training, hazard recognition, and fall-protection instruction before use. - OSHA Publication 3842 – Working Safely with Scissor Lifts:

Directs that elevated driving is only allowed if the manufacturer’s manual specifically states such operation is safe under defined surface and speed conditions.

ANSI/SAIA Standards

- ANSI A92.20 – Design, Calculations, Safety Requirements:

Establishes equipment design and operational limits for Mobile Elevating Work Platforms (MEWPs), including “platform elevation while traveling” permissions, which apply only when explicitly authorized by the manufacturer. - ANSI A92.22 – Safe Use Standard:

Defines employer responsibilities for MEWP inspections, maintenance, and operator supervision, especially during motion while elevated. - ANSI MH29.1-2020 – Industrial Scissor Lift Safety Requirements:

Governs load resistance, tipping thresholds, and hydraulic stability. It requires in-built safety features such as tilt alarms and automatic leveling to qualify for elevated driving.

ISO and International Standards

- ISO 16368:2024 – Mobile Elevating Work Platforms:

Specifies global performance and safety design criteria for elevated travel and operator protection, harmonizing ANSI and EN standards. - ISO 9386-1:2000 – Power-Operated Lifting Platforms:

Addresses mechanical, hydraulic, and control safety measures, including motion limits for platforms carrying persons.

Summary of Key Regulatory Conditions

- Driving elevated is only allowed if approved by both manufacturer and standards (ANSI A92.20 / MH29.1).

- Operator training and MEWP certification per ANSI A92.24 and OSHA §1926.454 are mandatory.

- Operation must occur on level ground, under safe wind limits, and at manufacturer-specified speeds.

In essence, elevated scissor lift movement is not banned outright—but it is tightly regulated under OSHA scaffold provisions, ANSI A92 safety codes, and ISO 16368 design standards to ensure stability and operator protection.

Which specific OSHA sections apply to scissor lifts in construction

In construction, scissor lifts are regulated under OSHA’s 29 CFR Part 1926, primarily classified as mobile scaffolds rather than aerial lifts. Several key OSHA sections directly apply to their safe use, training, and fall protection requirements.

Core OSHA Regulations for Scissor Lifts in Construction

| OSHA Section | Title | Key Requirements for Scissor Lifts |

|---|---|---|

| §1926.451 | General Requirements for Scaffolds | Scissor lifts must support at least four times their maximum intended load; guardrails must be in place; fall protection applies to platforms over 10 ft high . |

| §1926.452(w) | Mobile Scaffolds | Covers scissor lifts because they are mobile scaffolds. Prohibits movement with workers on the platform unless the surface is firm and level, and manufacturer permits it . |

| §1926.454 | Training Requirements | Employers must train employees to recognize hazards such as tip-overs and falls, and ensure only trained personnel operate lifts . |

| §1926.20(b) | Accident Prevention Responsibilities | Requires employers to use only safe, compliant equipment and ensure workers are qualified and properly trained . |

| §1926.21(b)(2) | Employer Responsibility for Safety Instruction | Mandates adequate safety instruction on recognizing and avoiding hazards specific to scissor lift operation . |

| §1926.451(g)(1)(vii) | Fall Protection | Workers must be protected by guardrails or personal fall arrest systems when working on elevated scissor lift platforms . |

| §1926.503 | Fall Protection Training Program | Requires employers to provide formal fall protection training, including proper use of guardrails and harness systems . |

Clarifying the Classification

Scissor lifts are not aerial lifts under §1926.453, which applies only to vehicle-mounted, rotating work platforms like boom lifts. OSHA clarified that scissor lifts instead fall under Subpart L — Scaffolds because their platforms move vertically without rotation.

Key OSHA Guidance Documents

- OSHA Publication 3842 – “Working Safely with Scissor Lifts”: Outlines safe setup, stability requirements, and inspection rules.

- OSHA eTool for Scaffolding – Scissor Lifts (2025): Provides step-by-step compliance instructions for lift operation on construction sites.

In summary, for construction operations, the primary OSHA standards governing scissor lifts are 29 CFR §§1926.451, 1926.452(w), 1926.454, and 1926.20(b). Compliance with these ensures stability, proper load support, fall protection, and adequate operator training on job sites.

Which OSHA provisions require fall protection on scissor lifts

OSHA requires fall protection for scissor lifts under several specific provisions within 29 CFR Part 1926 Subpart L (Scaffolds) and Subpart M (Fall Protection). Scissor lifts are categorized as mobile scaffolds, not aerial lifts, and workers must be protected through either guardrails or a personal fall arrest system (PFAS) depending on the lift’s configuration and condition.

Key OSHA Provisions Requiring Fall Protection

| OSHA Section | Title | Requirement Summary |

|---|---|---|

| §1926.451(g)(1)(vii) | Fall Protection for Scaffolds | States that for all scaffolds (including scissor lifts), each employee must be protected by a personal fall arrest system or guardrail system. Properly installed guardrails meet OSHA’s fall protection requirements for most scissor lifts . |

| §1926.451(e)(9) | Access & Egress Safety | Requires workers to remain inside the guardrail structure during elevation and descent; climbing or leaning beyond rails is prohibited . |

| §1926.454(a) | Scaffold User Training | Mandates that employees be trained on fall hazards and proper use of fall protection equipment associated with scissor lifts . |

| §1926.501(b)(1) | Duty to Have Fall Protection | Requires fall protection whenever employees are working six feet or more above a lower level, reinforcing lift guardrail and PPE use . |

| §1926.503(a) | Fall Protection Training Program | Requires employers to ensure that every worker exposed to a fall hazard has received comprehensive fall safety training . |

OSHA Interpretation of Scissor Lift Fall Protection

- Guardrail Systems: OSHA recognizes a well-maintained guardrail system as sufficient fall protection when workers remain inside the platform.

- Personal Fall Arrest Systems (Harness + Lanyard): Required only if guardrails are missing, damaged, or removed, or when workers must reach or step outside the guardrail-protected area.

- Tie-Off Rules: Workers must never tie off to guardrails, as these are not designed to serve as anchor points.

Related OSHA Guidance Documents

- OSHA eTool: Scaffolding – Scissor Lifts (2025) confirms that fall protection is required through 29 CFR 1926.451(g) and that guardrails must always be in place.

- OSHA Standard Interpretation (Letter dated July 21, 1998): Clarifies that scissor lifts fall under §1926.451, and workers need only be protected by guardrails, unless those guards are inadequate.

- OSHA Publication 3842 – Working Safely with Scissor Lifts: Reinforces proper guardrail use, PPE, and fall prevention training requirements.

In short, OSHA 29 CFR §§1926.451(g)(1)(vii), 1926.501(b)(1), and 1926.503(a) are the primary regulatory provisions requiring fall protection for scissor lift use. Guardrails usually fulfill this obligation—but if they’re compromised or workers move outside them, a personal fall arrest system becomes mandatory.