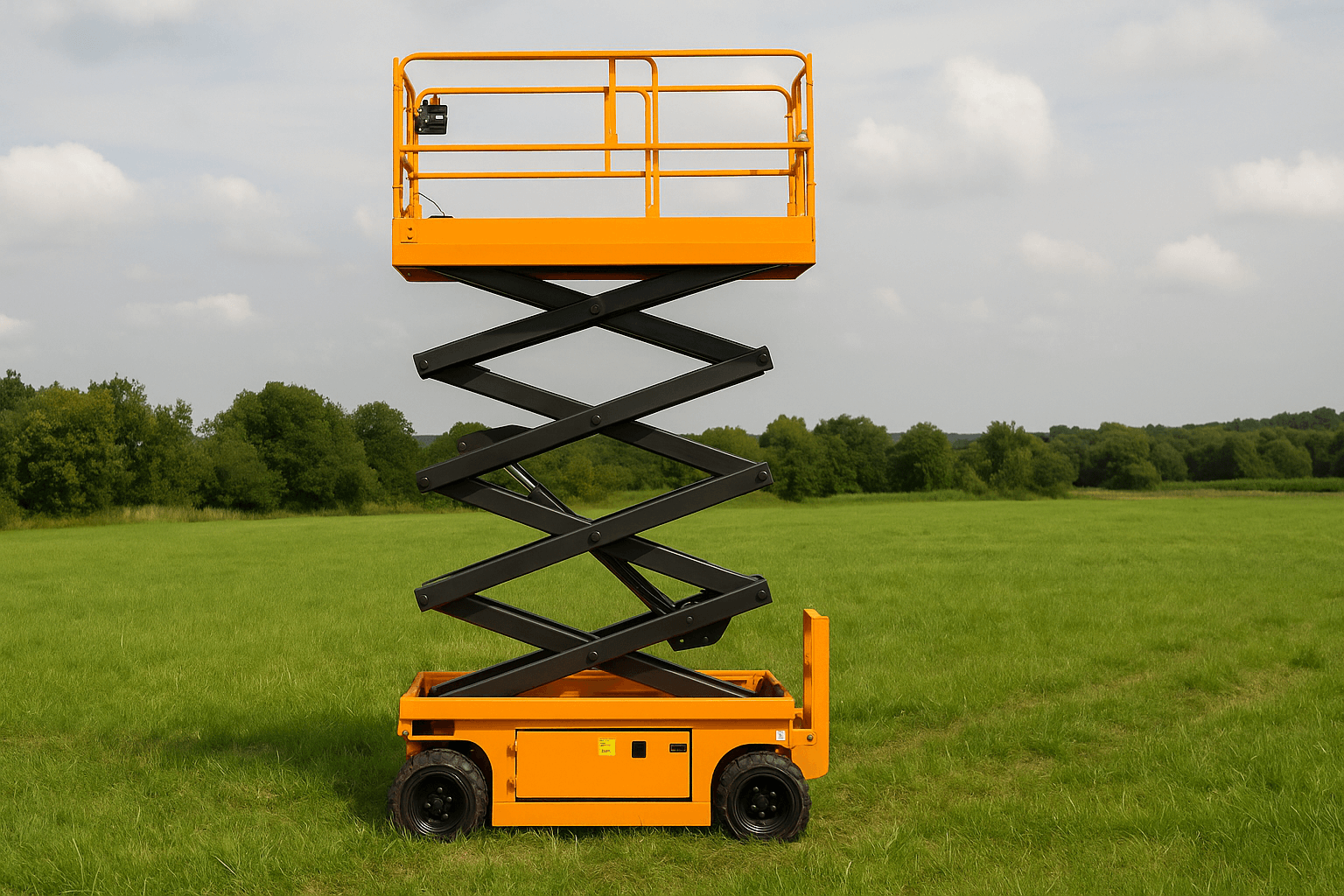

Scissor lifts are invaluable tools in construction, maintenance, and industrial operations, offering safe vertical access for a variety of tasks. However, when work sites feature natural terrain, such as grass, questions arise about whether a scissor lift can be safely operated on these surfaces. This guide dives deep into the considerations, risks, and safety measures surrounding the use of scissor lifts on grass.

Types of Scissor Lifts and Terrain Compatibility

Slab Scissor Lifts (Indoor/Hard Surface Lifts)

These lifts are designed primarily for smooth, firm surfaces like concrete or asphalt. They typically have lower ground clearance, solid rubber tires, and lack the rugged features needed for uneven or soft surfaces. Using slab lifts on grass is not recommended as they can easily sink, tip, or lose traction on soft or uneven ground.

Rough Terrain Scissor Lifts

Rough terrain scissor lifts are engineered for outdoor environments, including grass, dirt, gravel, and uneven surfaces. They feature:

-

Higher ground clearance

-

Aggressive, often pneumatic tires for better grip

-

Four-wheel drive or 4×4 capabilities

-

Stabilizers or outriggers for added balance

These lifts can be used on grass safely provided the ground is firm, dry, and relatively level. They are the preferred choice for grassy or uneven job sites.

Hybrid Lifts

Some models combine electric and diesel power or mix features of slabs and rough terrain lifts. Their suitability for grass depends on model specifics and ground conditions and should be evaluated case by case.

Risks of Using a Scissor Lift on Grass

Operating a scissor lift on grass carries specific risks, mainly related to surface conditions:

-

Ground Collapse or Sinking: Soft or wet soil may not support the lift’s weight, causing it to sink or become stuck.

-

Slipping and Sliding: Grass, especially when wet, can be slippery leading to poor traction and potential sliding.

-

Uneven Terrain Hazards: Roots, bumps, slopes, or holes hidden by grass may destabilize the lift and increase tip-over risk.

-

Reduced Stability: Elevated platforms on unstable grass surfaces amplify risks of tipping or collapse.

Best Practices to Operate on Grass Safely

1. Choose the Right Equipment

-

Always prefer rough terrain scissor lifts for grassy terrain.

-

Ensure the machine is equipped with off-road tires, stabilizers, and sufficient ground clearance.

2. Inspect the Site Thoroughly

-

Check for hidden holes, soft patches, slopes, or wet areas.

-

Avoid the lift use during or after heavy rain when the ground is soaked or muddy.

3. Use Ground Protection

-

Employ plywood sheets, rubber matting, or specially designed ground pads to distribute the weight more evenly and prevent sinking.

4. Adhere to Load and Operation Limits

-

Do not exceed the weight limit of the lift.

-

Keep loads balanced to maintain a stable center of gravity.

5. Follow Manufacturer Guidelines

-

Refer to the operator’s manual for specific terrain use ratings.

-

Do not attempt to use slab-type lifts on grass.

6. Monitor Weather Conditions

-

Avoid operating lifts on grass when windy, wet, or otherwise unsafe due to environmental factors.

What to Avoid

-

Do not use slab scissor lifts or indoor lifts on grass.

-

Avoid operation on excessively soft, sloped, or uneven grassy terrain without proper stabilization.

-

Do not attempt to move the lift if stuck without proper equipment and procedures.

Summary

Can a scissor lift be used on grass? The answer is yes, but only with the right type of lift (rough terrain) and under safe conditions. Preparation, equipment choice, and thorough site assessment are critical to prevent accidents such as tipping, sinking, or slipping. When in doubt, consult the lift manufacturer’s specifications and prioritize safety measures like ground mats and load management.

Following these precautions ensures efficient, stable, and safe operation of scissor lifts even on natural grassy terrains.

What types of scissor lifts are best for outdoor grassy areas

The best types of scissor lifts for outdoor grassy areas are rough terrain scissor lifts and certain hybrid models designed for uneven or soft ground. These lifts offer features that ensure safe and stable operation on grass, including:

Rough Terrain Scissor Lifts

-

Equipped with high ground clearance to avoid getting stuck in uneven grass or soil.

-

Use aggressive, often pneumatic tires that provide superior traction on soft or slippery surfaces like grass.

-

Often have four-wheel drive (4×4) or all-wheel drive for better maneuverability outdoors.

-

Include outriggers or stabilizers to enhance balance and stability on uneven terrain.

-

Built with stronger suspension systems to handle bumps and rough ground.

These lifts are ideal for construction sites, landscaping, and other outdoor tasks on grassy areas.

Hybrid Scissor Lifts

-

Combine features of electric and diesel-powered lifts.

-

Some models offer rough terrain capabilities with quieter electric operation.

-

Suitable for users needing flexibility for partly indoor and outdoor use, including grassy areas depending on specifications.

Proper evaluation of the model’s terrain rating and features is necessary.

What to Avoid

-

Slab or indoor scissor lifts with solid, low-clearance tires are unsuitable for grass as they lack traction and ground clearance, risking sinking or tipping.

In summary, rough terrain scissor lifts are the best choice for outdoor grassy environments due to design elements tailored for soft, uneven ground. Hybrid models may be suitable depending on specific features and conditions.

What safety precautions are essential for outdoor lift operation

Essential safety precautions for outdoor scissor lift operation include:

Site Assessment and Preparation

-

Inspect the ground for stability, avoiding soft, uneven, or sloped surfaces that may cause tipping or sinking.

-

Remove debris, obstacles, and hazards from the work area.

-

Use ground protection mats if the soil is soft or vulnerable to damage.

Choosing the Right Equipment

-

Select lifts designed for rough terrain with adequate ground clearance, appropriate tires, and stabilizers.

-

Confirm equipment is rated for the specific outdoor conditions and task requirements.

Weather Monitoring

-

Avoid operation in high winds, rain, or storm conditions that can compromise lift stability and operator safety.

-

Halt work if weather changes suddenly during elevated tasks.

Safe Operation Practices

-

Always operate lifts on firm, level ground when elevated.

-

Lower the platform fully before moving unless the lift is designed for elevated movement.

-

Adhere strictly to load limits and ensure even load distribution.

-

Use spotters when visibility or maneuverability is limited.

Fall Protection and Personal Protective Equipment (PPE)

-

Use fall arrest harnesses attached to designated anchor points.

-

Wear hard hats, safety boots, and other required PPE for the site.

Training and Certification

-

Ensure operators are properly trained and certified according to OSHA, ANSI, or local regulations.

-

Training should include hazard recognition, emergency procedures, and manufacturer guidelines.

Emergency Preparedness

-

Have rescue plans and equipment ready for retrieving operators in case of malfunction or emergency.

-

Maintain clear communication channels among personnel on site.

Following these safety precautions helps prevent accidents and ensures efficient, safe use of scissor lifts in outdoor environments