Electric Scissor Lift & Automated Scissor Lift: Scissor Lifts Changing the Game in 2026

By the year 2026, the scissor lift market is witnessing a radical change that is mainly due to the use of electric and automated scissor lift systems. This change is altering the way professionals in construction, maintenance, event production, and warehousing perform tasks at heights using the advanced electric scissor lift.

Scissor lifts, which might have been considered as simple standard lifting platforms, are becoming the first choice of technology because they embrace the newest features introduced by the important changes in the electric drive and automated control units. The emergence of the technological trend goes well with the ever-increasing demand for a more efficient workplace, environmental friendliness, and strict safety rules.

Electrification Changes to the Scissor Movements

Electrification of scissor lifts is a significant measure in a long-term strategy rather than a short-lived fashion, as it is a response to the increasing demand for energy-saving and low-maintenance equipment. Compared to traditional diesel-powered machines, electrified scissor lifts bring their users zero emissions, reduced noise, and greatly fewer maintenance requirements, which makes them perfect for indoor usage and urban construction sites where air quality standards become more and more rigorous.

- Electric scissor lifts allow almost noiseless operations, which are very important for indoor construction sites, warehouses, events, etc., where noise suppression must be kept at a certain level.

- In the case of an electric machine, owing to fewer parts in motion and no need for changing engine oil or cleaning the exhaust system, maintenance costs and the service time is significantly reduced as compared with internal combustion counterparts.

- The battery technology of 2026 models has been greatly improved when it comes to the duration of work, charging speed, and performance during heavy cycles. Therefore, the machines can be used for 24-hour operations, typical of highly demanding workplaces.

- Such a green approach to the environment is not only good for helping companies cut their carbon emissions but it is also in line with worldwide sustainability goals and attracts clients who are giving priority to green building certifications.

Automation: The Next Phase of Smart Scissor Lifts

So fast is the transition to automate the scissor lifts that it is becoming a hallmark of the modern ones, as the producers are coupling the intelligent controls which aid not only the safety but also the productivity. In order to lessen the mistake of the operator and to expedite the work that’s repetitive, the automated scissor lifts can utilize the assortment of advanced sensors, the onboard diagnostics, and the programmable movement systems.

Among other safety devices, Safety interlocks, automatic platform leveling, and proximity sensors are now included in the basic equipment, thus, enabling the prevention of tip-overs as well as that of accidental contacts with obstacles or overhead hazards.

The semi-autonomous modes give the possibility to the operators to pre-record the lift sequences, thus, setting the platform to the required height and also, following the digital blueprints for exact installation work, thereby, enhancing the productivity and the consistency.

Furthermore, on-board diagnostics could be seen as automatic maintenance alerts which inform technicians of emerging issues that are still in their early stages thus, the equipment life span is prolonged and fleet utilization is optimized.

With such developments, not only seasoned operators are catered, but also the new entrants into the field that features simplification of operation and less dependency on skills which in turn more teams get empowered to undertake challenging projects safely.

Market Demand and Applications

The push towards electrification and automation was very much influenced by the changes in workplace requirements as industries looked for solutions that would balance operational efficiency with sustainability and safety. Indeed, in the year 2026, electric and automated scissor lifts’ applications have spread far and wide across various sectors, thus, generating an increased demand for such advanced models in the market.

- On construction sites, electric scissor lifts are preferred to be used so as to be able to meet the stricter regulations that are set to improve the air quality and reduce the noise pollution, in particular, for interior fit-outs and renovations.

- What is more, warehousing and logistics activities are empowered through the use of automated scissor lifts by means of efficient inventory storage, ease in maintenance at different heights, and swift changing of shelving systems to meet the demand.

- Moreover, the events industry is heavily dependent on small-sized and battery-powered platforms that are safe and accurate to be used for the rigging of lighting, audio, and stage elements mostly when the turnaround schedules are tight.

Therefore, the rental companies are now poised to add more electrified and automated scissor lifts to their fleets so as to keep up with the competition and be accommodative of their clients’ needs, whereas the end-users are benefiting from the increased uptime and at a lesser overall cost.

Essential Features of Next-Gen Scissor Lifts

- Scissor lifts in 2026 are going to be beyond the basic features with a comprehensive set of capabilities that allow them to reinvent productivity and workplace safety. The accent on the easy-to-use

- Lithium-ion batteries are equipped in the standard package that makes rapid battery recharge and consistent battery discharge over the full working day possible hence, there is no need to frequently change the battery or undertake long recharge intervals.

- By means of modular control panels equipped with touchscreens, the users of scissor lifts can proficiently choose the modes, observe the real-time system diagnostics, and retrieve the safety instructions that are context-dependent from the guidance accessed on demand.

- The changes are indeed a reflection of the opinions scissor professionals and maintenance teams express regarding their need for dependable and versatile machines which are capable of supporting dynamic work environments.

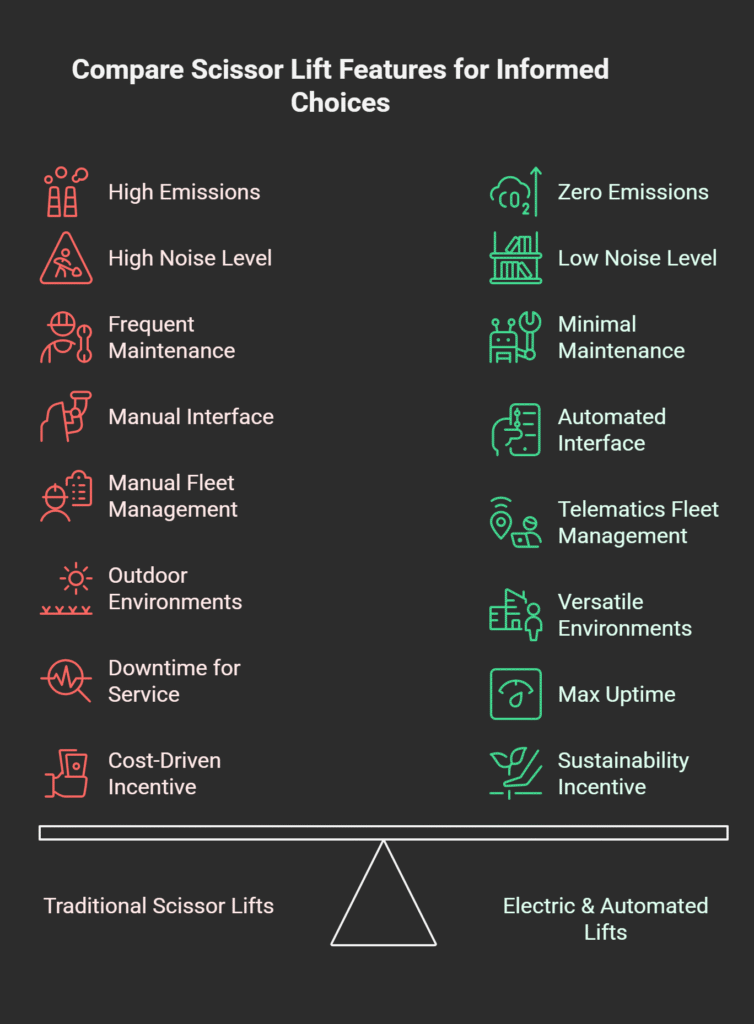

Table: Traditional vs. Electric & Automated Scissor Lifts

| Feature/Specification | Traditional (Diesel/Gas) | Electric & Automated (2026) |

| Emissions | High emissions | Zero emissions |

| Noise Level | High | Low/Whisper-quiet |

| Typical Maintenance | Frequent, intensive | Minimal, predictive |

| Battery/Power System | N/A | Lithium-ion standard |

| Operator Interface | Manual (no automation) | Touchscreen, automated controls |

| Fleet Management | Manual logs & checks | Telematics, remote monitoring |

| Application Environments | Outdoor, industrial | Indoor, outdoor, versatile |

| Uptime/Availability | Downtime for service | Max uptime with diagnostics |

| Adoption Incentive | Cost-driven | Sustainability, efficiency, safety |

The Role of Training and Certification

As the technology used in scissor lifts is advancing, the comprehensive operator training and certification are getting more and more important. The present-day training programs not only teach the machine operation but also include digital controls, telematics, battery management, and advanced automation features.

- Equipment rental companies have introduced modular courses for electric and automated scissor lift operations, which include virtual modules and on-the-job training, facilitated by specialized trainers.

- The use of e-learning platforms has been on the rise as they offer basic knowledge and safety awareness in a convenient and flexible manner; however, skill assessment is still a must for getting certified.

- Employers are keen on continual staff training as it helps keep them abreast of new safety features and regulation changes, especially since automation leads to new operational paradigms.

- Giving proper attention to training and getting the relevant qualifications not only ensures working within legal frameworks but also lessens accidents in the workplace and enhances the return on investment of advanced equipment.

Maximizing ROI with Scissor Lift Automation

- Organizations with a forward-looking mentality are making full use of the return on investment (ROI) benefits that come with the use of automated and electric scissor lifts. This includes savings in costs, gains in productivity, and reduction in risks.

- The electric vehicles such as scissor lifts are more fuel-saving as well as less oil-needing and maintenance consuming and therefore, bring about a direct reduction of lifecycle costs as compared to their fossil-fueled counterparts.

- Automation lessens human errors, results in fewer injuries in worksites, and also, enables faster, and more consistent, thus, completion of tasks, hence, the two main benefits (safety metrics and project throughput) are improved.

- Telematics-enabled lifts bring about smart fleet management, asset tracking, and pre-emptive maintenance possibilities—thus, eases the operators achieving more with fewer machines and, at the same time, lessens the downtime.

- Thanks to these innovations, clients, managers, and equipment operators are experiencing significant improvements in project delivery, equipment reliability, and operational transparency.

Common Challenges and Future Directions

While great strides have been made in support of the concept, the uptake of the ideas electrification and automation in the case of scissor lifts is still hindered by difficulties. There are such problems as the initial purchase price, the setting-up of the charging station, the provision of comprehensive training on advanced features, and the integration of technology that further complicate the situation especially in small organizations and areas with old fleets of vehicles.

- Some worksites do not have the required electrical infrastructure to carry out large fleets of battery-powered equipment, which is why solutions for field charging and rapid deployment need to be developed creatively.

- Although automated safety systems enhance results, they require users’ acceptance and understanding — organizations have to constantly commit to skills development and technology acclimatization.

- Producers and rental companies are taking steps to make technology introduction easier through the use of cross-compatible platforms, upgradable software, and shared best practices.

By the same token, further innovations in AI-guided automation, ultra-fast charging solutions, and comprehensive digital training are expected to significantly increase the scope and the impact of the scissor lift electrification and automation, thus paving the way for new standards in 2026 and beyond.

FAQs on Electric Scissor Lift & Automated Scissor Lift

What is the main difference between traditional and electric scissor lifts?

Electric scissor lifts operate using battery-powered drive systems, producing zero emissions and lower noise—ideal for indoor use and green construction sites—while traditional models rely on diesel or gas engines, which emit pollutants and require more maintenance.

Are automated scissor lifts safe for new operators?

Yes, automated lifts feature safety interlocks, programmable movement limits, and intuitive controls that reduce operator error, making them especially safe for both experienced operators and newcomers with proper training.

How long do lithium-ion scissor lift batteries last on a single charge?

Modern lithium-ion batteries typically support a full day’s work (8–10 hours) on a single charge, depending on workload and platform size, with rapid charging enabling quick turnaround between shifts.

Can automated scissor lifts be used outdoors?

Many automated and electric scissor lifts are designed for mixed environments, with rough terrain models available for outdoor use featuring weatherproof components and heavy-duty tires.

How does telematics improve scissor lift fleet management?

Telematics systems enable real-time detection of faults, GPS tracking of machines, predictive maintenance alerts, and utilization analytics, optimizing fleet deployment and reducing unplanned downtime.

What are recommended training options for electric and automated scissor lifts?

Training is provided by equipment rental companies, accredited construction safety organizations, and e-learning portals, integrating hands-on modules with digital instruction to ensure both competence and compliance.

Is it more expensive to rent an electric scissor lift compared to a diesel model?

Rental costs are often similar or only slightly higher for electric models, but users typically benefit from lower fuel and maintenance costs, and many projects now demand electric lifts to meet environmental standards.

Conclusion: The Era of Electric Scissor Lift & Automated Scissor Lift

The revolution powered by electrification and automation in 2026 is changing the way industries handle the elevated work and jobsite safety. By going for electric and automated scissor lifts, companies make themselves the leaders of safe, efficient, and environment-friendly work practices.

As the technology is progressing further—with smarter batteries, AI-powered automation, and robust fleet management—the future is still capable of delivering more safety, productivity, and cost-effectiveness at higher altitudes. For those who want to be literally and metaphorically at a higher level, it is wise to keep abreast with and take up these innovations in the rapidly changing world of elevated work platforms.