ANSI Scissor lift Standards: Vital Information for Every Operator

Aerial work is a perfect example of safety first. Safety is a set of rules that the worker must follow without fail to get the job done and come back home in one piece. The ANSI Scissor lift Standards provide the minimum safety requirements for these powerful machines to be designed, maintained and operated with utmost precision.

By switching to the ANSI A92 suite of ANSI Scissor lift Standards, the industry has left behind the highly specialized categories of equipment and embraced a singular set of regulations that apply to Mobile Elevating Work Platforms (MEWPs) in general. This change has a profound impact on how we categorize our machines, train our workforce, and evaluate the hazards at the work site. Knowing these ANSI Scissor lift Standards could be the difference between a safe and successful day at work or a disastrous one.

The New Language of Safety: From AWPs to MEWPs

The most noticeable change that any operator will notice is the new jargon. Aerial Work Platforms (AWPs) have been renamed Mobile Elevating Work Platforms (MEWPs)

to better reflect their capabilities. This is more than just a name change; it is an important step towards the worldwide standardization of safety regulations. According to ANSI A92.20, scissor lifts are now described by their “Group” and “Type” as they indicate their stability and extent of their movement.

- Group A Classification: The platform of a scissor lift belongs to Group A as it never extends beyond the tipping lines (the chassis footprint) during its vertical movement.

- Type 3 Movement: A self-propelled scissor lift that is operator-controlled from the platform while it is elevated is therefore Type 3.

- Indoor vs. Outdoor Ratings: Newly approved safety requirements indicate that machines must come with markings specifying “Indoor Use Only” if they cannot withstand wind loads, or otherwise, there must be restrictions on their outdoor capacity.

The Three Pillars of the ANSI A92 Suite

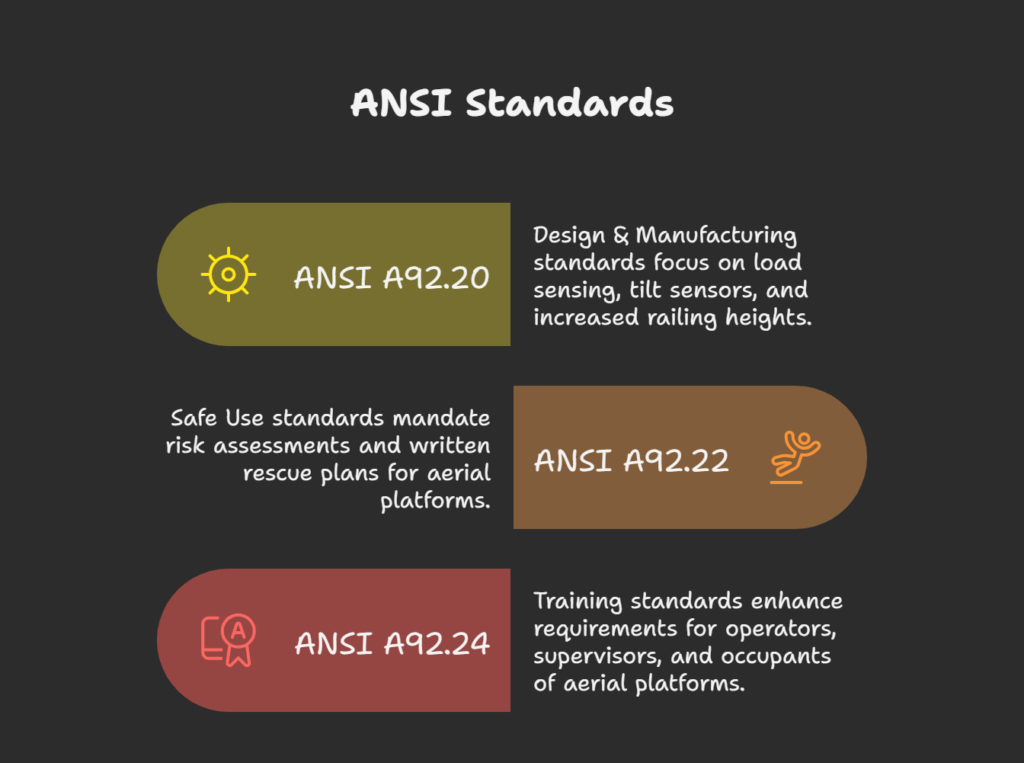

The present set of regulations is comprised of three separate documents, each addressing a different phase of the lifespan of the equipment. It is vital that operators and supervisors know how these regulations fit together to form a “safe use” environment.

| Standard | Focus Area | Key Requirements |

| ANSI A92.20 | Design & Manufacturing | Load sensing, tilt sensors, and increased railing heights. |

| ANSI A92.22 | Safe Use | Mandatory risk assessments and written rescue plans. |

| ANSI A92.24 | Training | Enhanced requirements for operators, supervisors, and occupants. |

- Design Innovations: Most recent innovations in design and technology. Lifts today come equipped with “Load Sense” features that basically tell the machine to stop working if it is overloaded.

- Built-in safety measures: “Tilt Sensors” are installed in the machine that will deactivate certain operations if the platform is placed on an incline which is beyond the limit set by the manufacturer.

- Physical barriers: Chain gates have been replaced with solid gates equipped with toe boards that keep the platform users from dropping anything such as tools or even their feet inadvertently.

Mandatory Requirements for ANSI Scissor lift Standards

1. Training for Operators and Occupants

Training has turned into a requirement for the entire workforce and not just the vehicle operator. One of the most significant changes in the ANSI A92.24 standard is the Occupant Training requirement. You do not necessarily have to be the driver of the lift to be trained as a platform occupant in order to learn the basics of safety and emergency measures that you could remember and apply even when the operator is not there.

- Supervisor Training: Supervisors who oversee MEWP operations are now required to receive specific training that will help them be capable of recognizing hazards and ensuring operators follow safe work practices.

- Occupant Briefing: The operator must make sure that everybody on the platform understands the provisions of fall protection, the operation of emergency lowering controls, and the identification of hazards at the site.

- Practical Evaluation: Holding a certificate is not sufficient as operators must also be capable of proving their competence through practical tests and be regularly assessed by qualified persons.

2. Site Risk Assessment and Rescue Planning

The deployment of a scissor lift can only take place after a thorough site risk assessment has been carried out. This is a non-negotiable requirement under ANSI A92.22. It is no longer permissible to simply “eyeball” the terrain; hazards must be identified, safety measures delineated, and the whole process documented.

- Hazard Identification: One must locate overhead power lines (keeping a distance of at least 10 feet), ground depressions such as potholes or lids of utilities, and weather conditions like winds and lightning.

- The Rescue Plan: If there is a mechanical failure or a fall with a worker being suspended in a harness situation, there must be a rescuing approach in writing. This plan should be communicated to the team and cover self-rescue as well as assisted rescue methods.

- Surface Integrity: The operator must evaluate whether the ground surface is sufficiently firm and level to carry the weight of the MEWP and the maximum load without the risk of the wheels sinking or the machine tipping over.

3. Equipment Inspection: The Daily Checklist

ANSI Scissor lift Standards come with a heavy focus on the “Pre-Start Inspection.” This is not just an easy checkbox; it means being the last barrier that can prevent a mechanical failure. Therefore, each operator should perform a walk-around at the start of every shift.

- Functional Tests: Make sure that all controls, including the emergency stop and manual lowering, are functioning correctly and respond as expected by the manufacturer.

- Component Integrity: While doing the checkup on the machine, one should look for cracks in the scissor stacks, the leakage of the hydraulic system, and wear or damages on the tires.

- Safety Decals: Check that all capacity charts, safety warnings, and the operator’s manual are still visible and readable on the equipment.

4. Stability and Fall Protection Requirements

If used as per the guidelines scissor lifts are very stable, however, they do have to conform to the laws of physics. Together, ANSI and OSHA define the fall people protection ANSI Scissor lift Standards which ensure that operators are kept safely on the platform.

- Guardrail ANSI Scissor lift Standards: New design of ANSI Scissor lift Standards have bumped up the height of the required railing to 43.5 inches (1.1 meters) giving the user even better protection against falls.

- Fall Restraint vs. Arrest: A scissor lift’s guardrail system is the main type of fall protection, but various policies or configurations may need a harness and lanyard fastened to an approved anchor point.

- Stability Factors: Never place ladders or wooden planks on the platform to add height. Always make your movements controlled and smooth, particularly when the lift is both elevated and moving around the work area.

FAQ’s ANSI Scissor lift Standards

What is the difference between OSHA and ANSI for scissor lifts?

OSHA i.e. the Occupational Safety and Health Administration is a government agency that is responsible for setting and enforcing the mandatory regulations under the law while ANSI is a non-governmental organization that establishes “best practice” industry ANSI Scissor lift Standards. Even though ANSI is not a law, OSHA frequently incorporates ANSI Scissor lift Standards by reference, thus compliance with ANSI is practically a must for any legally safe operation.

Can I move a scissor lift while the platform is raised?

Yes, only if the manufacturer’s manual explicitly allows it and the ground is level and firm. The majority of modern self-propelled scissor lifts (Group A, Type 3) permit traveling at a slow speed while the platform is elevated, but you must always be on the lookout for overhead obstacles and ensuring that you are within the limits of the tilt sensor.

Do I need a harness on a scissor lift according to ANSI?

ANSI A92 states guardrail could be the main “fall protection” system but at the same time personal fall arrest system (PFAS) or fall restraint are highly recommended and are often required by the specific work site or situations where “catapulting” from the platform is a real hazard (mostly boom lifts only but scissor lifts could be hit by a vehicle).

What is the “Load Sense” system on new scissor lifts?

A92.20 standard introduced Load Sense, which is an automatic weight detection device that measures the total weight on the platform. If the weight goes beyond the rated capacity, the system first gives a warning signal and then locks the lift as well as the drive functioning to prevent a tip-over or a failure of the structure.

How often do I need to be retrained on a scissor lift?

Under ANSI A92.24 operators should be given retraining if they are caught operating the machine in an unsafe manner, if a new MEWP is being introduced at the worksite, or if the period of their last operation has been significantly long. However, most businesses as a good practice have their workers undergo recertification every 3-5 years.

What are the wind speed limits for outdoor scissor lift use?

According to ANSI ANSI Scissor lift Standards, the maximum allowable wind speed for scissor lifts that are rated for outdoor use is 28 mph (12.5 m/s). If the wind velocity is higher, then the platform needs to be lowered immediately. Units that have the label “Indoor Use Only” correspond with a wind speed rating of 0 mph.

Is a rescue plan really required for every job?

Yes. A written rescue plan is an absolute requirement for all MEWP activities as per ANSI A92.22. The plan should solve problems like getting the operator off the platform if the machine breaks down or if the worker is suspended in a harness post-fall thereby making sure aid arrives well before suspension trauma.