Digital Solutions: a must-have for operators of aerial work platform in construction

Construction is one of the industries that are moving from a world of physical hard labor to a more digital and data-driven world very fast. At the forefront of this change is the use of technology in heavy machinery, especially in terms of access equipment among aerial work platform.

Digital solutions for aerial work platform operators have become a vital measure for site safety, a key driver of operational efficiency, and a way to get the most out of one’s assets on the construction site.

For many years, scissor lifts and boom lifts were just considered tools—machines with hydraulics working as muscle to finish the task. Nowadays, however, they are components of a bigger digital network.

This progress is not about adding more features; it is about changing the way work at height is done, fundamentally. With the development of more complicated projects and shorter schedules, being able to monitor, analyze, and optimize equipment usage provides efficiency on project execution.

The Rise of Digital Solutions in Construction

Industry 4.0, characterized by connectedness, automation, and real-time data, is the main driver behind the adoption of digital solutions for the operation of aerial work platforms. In the old days, a manual fleet management of aerial lifts involved paper-based inspections and reactive maintenance schedules that often led to breakdowns without warning.

Today, digital platforms allow for a proactive management style in aerial work platform, where every single detail of a machine’s performance is measured and scrutinized.

For an operator, the implication of this change is, no doubt, huge since they are usually under pressure to get the job done on time and cannot afford a breakdown. A scissor lift or boom lift fitted with digital monitoring equipment can thus be considered more than just a static asset, it is an active and intelligent workmate on-site.

This high level of connectedness means that even if a piece of equipment is located miles away, the fleet manager still has a complete line of sight for making smarter decisions and thus optimizing resources.

The use of these advanced tools does not only add to the convenience factor but changes the aspect of risk at the construction site by giving detailed information on the usage or abuse of the equipment. Going forward, operators who are quick to adopt and learn about the benefits of these gadgets will be the ones who win in future construction projects.

- Instant fleet monitoring: Digital control panels give operators and fleet managers real-time access to the number, location, and status of machines, thus eliminating guessing in asset management.

- Proper and timely maintenance: An alert system that gives the operators notifications based on usage hours and not on calendar days makes sure that the machine is serviced at the correct time, thus eliminating costs that may result from over-maintenance or under-maintenance.

- Highly optimized asset utilization: With usage data on hand, companies can use data analytics services to properly size their fleets, reduce their rental expenses, and keep their in-house assets highly utilized.

Smart Sensors and Telematics: The New Standard

A very noticeable aspect of aerial work platforms’ digital progress is marked by smart sensors and telematics. These small parts of a bigger machine act as the machine’s nervous system, they perpetually collect data on the machine’s hydraulic pressure, battery health, load weight, and platform tilt.

As a case in point, scissorlifts.org shares modern options to upgrade eras-old machinery by equipping them with smart sensors. More than mere data recorders, these devices also work on interpreting data to produce useful insights.

For example, the maintenance team may be informed about the weakening condition of the hydraulic pump through pressure fluctuations and temperature changes, thus they can fix the issue before the pump breaks down entirely. Such a facility, nowadays called predictive maintenance, is great for a substantial reduction of downtime.

- Remote Health Monitoring: Constant follow-up of vital components such as battery voltage and hydraulic fluid temperature enables early identification of failure possibilities.

- Usage-Based Analytics: Detailed information on engine hours and idle time provided by telematics helps managers pinpoint inefficiencies and optimize fuel or battery consumption.

- Geofencing Capabilities: Digital solutions empower managers to define virtual boundaries for their equipment which generates alerts if the machine is moved outside of its authorized zone, thus theft and unauthorized use are prevented.

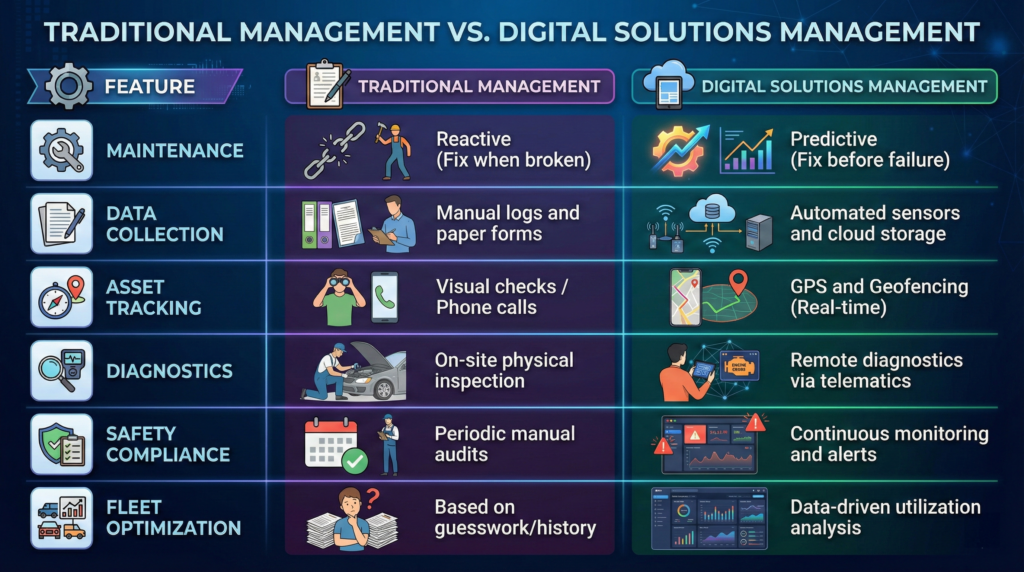

Comparison: Traditional vs. Digital AWP Management

| Feature | Traditional Management | Digital Solutions Management |

| Maintenance | Reactive (Fix when broken) | Predictive (Fix before failure) |

| Data Collection | Manual logs and paper forms | Automated sensors and cloud storage |

| Asset Tracking | Visual checks / Phone calls | GPS and Geofencing (Real-time) |

| Diagnostics | On-site physical inspection | Remote diagnostics via telematics |

| Safety Compliance | Periodic manual audits | Continuous monitoring and alerts |

| Fleet Optimization | Based on guesswork/history | Data-driven utilization analysis |

Making Safety Better with AI and Automation

In the Aerial Lift business, where Operator Safety comes first at all times, digital solutions for aerial work platform safety have changed the game to the advantage of the workers. Machine manufacturers employ Artificial Intelligence to help operators safely navigate complex surroundings by providing assistance via Advanced Control Systems.

For instance, the number of collision avoidance systems are increasing nowadays in the lifts, which use ultrasonic or radar sensors for detecting the presence of obstacles in the immediate vicinity of the platform.

It is possible for these systems to gradually halt or completely stop the machine when an operator is about to collide with a structure or an overhead hazard, thereby avoiding accidents.

At the same time, the detection of the load’s weight and the distribution of the load are not the only things that load sensing technology has come to be concerned with. The digital system in aerial work platform constantly evaluates the load’s distribution and stability, as well as the platform’s position, while it calculates the center of gravity at any given moment.

- Collision Avoidance Systems: Several sensors that help in identifying the presence, location, and movement of other systems such as other workers, machinery, or a vehicle around the working platform, thereby preventing any sort of collision.

- Active Stability Management: It helps in continuously monitoring of mode earth slope and platform load ensuring that the machine is operated within its safe operating envelope, thereby actively preventing dangerous operations.

- Operator Access Control: Such systems use digital keypads or RFID card readers for allowing the machine to be operated only by trained and authorized personnel for strict adherence to safety regulation practices.

Industry 4.0: Revolutionizing scissor and boom lifts

Industry 4.0 is transforming manufacturing and construction, and the digital solutions for aerial work platform equipment sector stand to benefit greatly from it. This fourth industrial revolution is all about how well and easily can machines and systems communicate with one another.

One example of this cross-connectivity is that a scissor lift can now be fully integrated with Building Information Modeling (BIM) software. Instead of having to carry a set of paper blueprints down to the work area, the operator simply opens up the tablet mounted on the scissor lift platform, and they have the digital plans right there at their fingertips.

This not only makes the job faster but also ensures greater accuracy, fewer mistakes, and less rework. Furthermore, the electrification push for 2026 and beyond will get a huge boost from digital tech. Electric and hybrid lifts will utilize advanced Battery Management Systems (BMS) to manage power delivery and charging cycles.

- BIM Integration: Direct access to digital construction models from the platform interface allows for precise positioning and installation, thus resulting in reduced errors and rework.

- Smart Battery Management: Sophisticated algorithms are used for optimizing the charging and discharging of electric lifts, thus leading to an extension of battery life and ready availability of the machines for full shifts.

- Interconnectivity: Machines can communicate to each other regarding the conditions present at the job site, e.g. identifying slippery terrain or wind gusts, thereby warning the rest of the units about the potential hazard.

The Importance of Digital Training and VR

Proper training and successful certification play a very significant part in ensuring the safety of users/operators working on aerial lifts. The introduction of digital solutions for aerial work platform training has been a great boon, making the educational process much more engaging and productive.

The conventional mode of study in the classroom is presently receiving additional support and, in some instances, substitution by the use of Virtual Reality (VR) simulators.

- Immersive Hazard Simulation: Using VR, an operator can be trained to handle situations involving the risk of the platform tipping over or being trapped in a controlled environment with no risks to life and property.

- Performance Tracking: Operator performance on digital training courses is deterministically recorded and specific metrics on operator proficiency are noted, thereby enabling identification of the area where the individual needs further coaching or practice.

- Automated Certification Management: A cloud-based solution is utilized to monitor licenses and certifications, automatically sending notifications to managers and operators when the renewal dates are due.

Future Trends: What 2026 Holds for Aerial Work Platform

It is an age of rapid transformation for digital solutions for aerial work platform and the progression will not be stopping anytime soon. Among other things, 2026 will witness a bigger level of autonomy.

The technology enabling lifts to follow a ‘leader’ or to autonomously drive themselves to a certain point within a job site has already been unveiled.

What these kinds of technologies accomplish is to completely remove the operator’s troubles from the lifting device handling part, thus the operator’s full concentration can be on the actual task such as welding, painting, or working with electrical equipment. Not to forget, 5G integration will be a huge game-changer in data transmission.

- Semi-Autonomous Operation: Future lifts will be equipped with “follow-me” modes and auto-positioning features, thus minimizing the need for manual input during repetitive movements.

- 5G Connectivity: Ultra-fast and real-time data transmission with low latency will facilitate real-time video collaboration as well as remote control of machines from any part of the globe.

- Predictive AI Analytics: Future algorithms will not just be able to predict mechanical failures but will also be capable of analyzing workflow patterns to recommend operational changes that can save both time and money.

FAQs on Digital Solutions for Aerial Work Platform

What is Industry 4.0 and how is it related to scissor lifts?

Industry 4.0 is all about smart digital technologies transforming the way we produce goods and manufacture products. For a scissor lift, it is about IoT devices, telematics, and data analytics that connect the machine to the internet. Consequently, it becomes possible to see the machine’s health, location, and usage in real-time. Basically, a scissor lift thus turns into a “smart” machine that makes a construction site safer and more productive.

Are electric scissor lifts a part of the Industry 4.0 trend?

Electric scissor lifts definitely represent a large chunk of Industry 4.0’s focus. These new electric lifts often have built-in smart battery management and digital control systems that communicate data regarding the battery’s level of charge and power usage. Digital tools that help optimize the performance and lifespan of the electric powertrain are in line with Industry 4.0’s sustainability and energy efficiency focus.

What progress can be expected in aerial work platforms by 2026?

We will see improvements such as greater autonomy (semi-autonomous driving and positioning), more extensive implementation of AI for predictive maintenance, and the use of 5G for real-time data transfer, in addition to that, security features such as automated collision avoidance, advanced operator interfaces that are integrated with digital construction plans (BIM), will be introduced extensively.

How is the aerial work platform industry going to tackle energy efficiency?

Energy efficiency is basically being tackled by switching to electrical and hybrid drive systems, which are then optimized by means of digital management software. Nowadays, new models come equipped with regenerative braking and auto-idle systems that are controlled by smart processors for an efficient use of energy. Furthermore, telematics data allows the fleet manager to identify and cut down on fuel wastage i.e. unnecessary idling and thus ensure that energy is used only for productive work.

How can smart sensors help recondition old scissor lifts?

Existing scissor lifts can be retrofitted with smart sensors at a much cheaper rate compared to the cost of buying new ones. These sensors are capable of monitoring the hydraulic pressure, tilt angles, and load weights and provide data which can then be used for remote diagnostics and safety alerts. Apart from reducing the maintenance costs and the number of maintenance visits, this also makes the equipment safer and extends its working life.

Does one have to undergo digital training for aerial work platforms?

Operator training that meets the requirements of safety organizations such as OSHA and ANSI is one of the basics. However, “digital” training specifically (like VR) is not legally mandatory. That said, digital training approaches are fast becoming the standard in the field because they offer better record-keeping and shady-practice-free, simulation-based learning in the alignment of the safety goals. Many employers have made a norm of these digital modules to ensure a highly competent workforce.

How can digital solutions enhance AWP operators’ safety?

Digital solutions help to safeguard the operators through active safety mechanisms. Some of the safety features that have been incorporated into the digital solutions include tilt sensors, load monitoring systems, and collision avoidance technology which are capable of automatically stopping the machine when an unsafe situation arises. Telematics provides the function of “access control”, which means that only trained and authorized operators can use the machine and since unauthorized usage is a major factor causing accidents, it is thus prevented by this measure.