Lights transform the holidays: The Role of Scissor Lifts for Festive Lighting in the Installation

Everyone loves pretty lights around the holidays; they have a way of turning normal places into something magical. It could be a crazy Christmas lights display in a mall, a fancy Holiday party at a company, or the lights for Diwali all over a city! What if I say, your installation task are made easy by choosing the best role of scissor lifts for festive lighting.

Whether you want to get light installations to crazy heights safely and efficiently, or looking for more than just loads of twinkly lights. You’ll need some serious equipment like scissor lifts for festive lighting.

Importance of Scissor Lifts for Festive Lighting

The use of scissor lifts for festive lighting installation is now a must-have tool for professional decorating teams and building managers. No more relying on rickety old ladders or heavy scaffoldings that not only weigh you down but also consume most of your precious setup time. The secret these days for getting the job done quickly, safely, and accurately lies in the use of modern elevating work platforms.

Besides the actual lighting installation, holiday decoration planning is usually a nightmare when it comes to logistics! Nine times out of ten, it feels like you’re racing against time to put up the decorations before the grand opening when you will be working during the quietest hours just to get things done.

The strategic deployment of scissor lifts for festive lighting in these situations offers you a win. These are machines that allow a safe, steady working area for skilled workers, who then have both hands free to do the job – something almost inconceivable on a ladder.

Why Role of Scissor Lifts for Festive Lighting Installations should be the preferred choice

One of the main attraction points between scissor lifts and festive lighting is the effectiveness of scissor lifts in providing a stable working area to the operative compared to other sources that can be used to access high places.

He or she can thus be assured of safe footing when the person hanging the heavy garlands or intricate light curtains at heights of twenty to forty feet. A scissor lift goes up and down on a mechanism that resembles an “X” which can thus be trusted to give a solid non-shaking platform that can hold quite a heavy weight.

The building materials and the overall design of the lift are well thought out so that the platform will indeed maintain its rigidity and not flex when in use and extended to the maximum height, thereby giving the uplifting workers the much-needed trust and peace of mind to be able to fully concentrate on the rather delicate work of arranging the lights and not on their balance.

Further to this, the dimension of the platform of the scissor lift is an aspect that really should not be overlooked. When compared to a ladder which basically only has a single, very narrow step, or a boom lift which more often than not has a smaller “bucket,” the platform of a scissor lift is one that unquestionably boasts a very generous amount of space.

Hence, you can have even two workers at once up on the platform each carrying a separate box of decoration items or the installed tools along with their own bodies. The interactive spirit of the work then jointly carried out becomes a productivity booster of the greatest magnitude in the face of wintry conditions and worsening of situations in general.

- Platform Stability: The vertical lift design helps keep the platform from swaying, so it is safer for the workers who are handling fragile glass bulbs or heavy wiring.

- Weight Capacity: The majority of standard scissor lifts have a load capacity of between 500 and 1,500 lbs, which is more than enough for two technicians and hundreds of pounds of lighting equipment.

- Workspace Area: With an extended deck, the lift can be used not only as a platform but also for “staging” the materials at height, so less time is spent bringing down the lights after lifting them up.

Efficiency and Speed in Professional Decorating

Time is money and no more so than in events and commercial decorating industry. The high impact of scissor lifts in festive lighting installation is most strongly evidenced through operations efficiency.

Traditional scaffolding take considerable time to put up and take down, sometimes these actions are even spaced out over several days. On the other hand, a mobile scissor lift is something you can drive up your working spot and have it ready for an operator to get up in mere seconds, plus you can move it to the next location right after you’ve finished the area.

Say for instance a shopping mall if that shopping mall is in the mood to cover the columns with light wraps or hang wreaths from the top of, the atrium, then this kind of maneuvering speed will be made possible.

Outdoor trees and streetlight posts especially when wrapped with lights are the ones that get most people thinking and which make them want to give up round. In the case of quite a few such kind of cases, a rough terrain scissor lift with the operator/drivers in them are always well enough, that means the operator does not have to get off the scissor lift and the driving can still continue in that area that gets elevated.

Thus, it is like you will have gone over a row of trees with your string of lights and by the time you reach the end of the last tree, your lights are fully strung.

- Rapid Deployment: It generally takes no more than mere minutes to make a scissor lift ready for operations at a job site and, if you compare this to the time that would be taken to set up scaffolding, you will agree with me that this is a very significant difference.

- Drive-While-Elevated: Some newer electric ones are equipped with this feature which enables operators to move the lift around without having to lower it completely, thus, making the workflow leaner, faster and more efficient for linear installations.

- Less Exhaustion: Installers’ energy level in the work area stays high because they do not have to get up and down the ladder repeatedly. As a result, they will be more focused and work of higher quality with fewer errors.

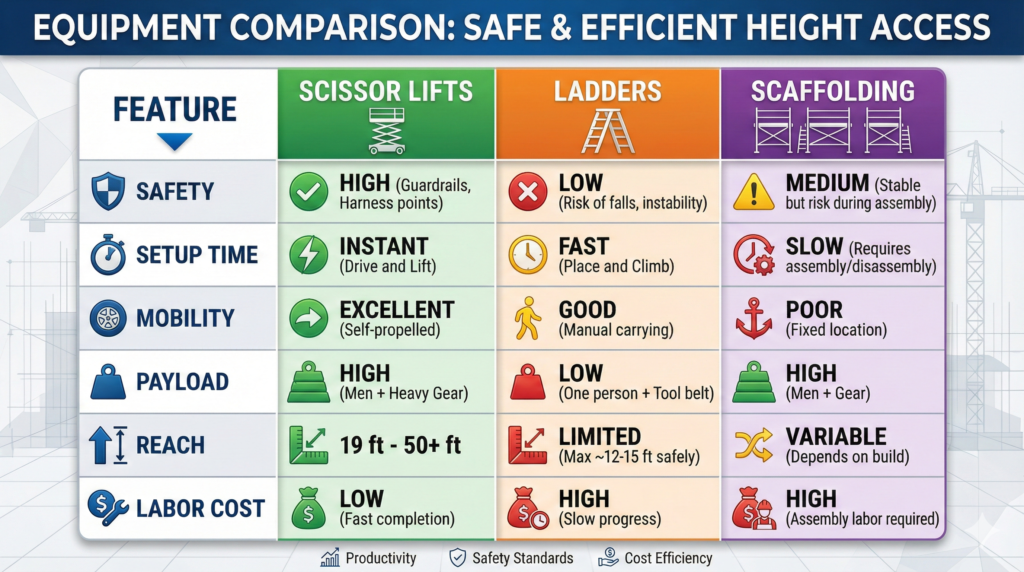

Comparing Elevation Methods: A Decorator’s Guide

To truly understand why the industry has shifted toward aerial platforms, it is helpful to look at a direct comparison. Below is a breakdown of why utilizing scissor lifts for festive lighting outperforms older, more manual methods.

| Feature | Scissor Lifts | Ladders | Scaffolding |

| Safety | High (Guardrails, Harness points) | Low (Risk of falls, instability) | Medium (Stable but risk during assembly) |

| Setup Time | Instant (Drive and Lift) | Fast (Place and Climb) | Slow (Requires assembly/disassembly) |

| Mobility | Excellent (Self-propelled) | Good (Manual carrying) | Poor (Fixed location) |

| Payload | High (Men + Heavy Gear) | Low (One person + Tool belt) | High (Men + Gear) |

| Reach | 19 ft – 50+ ft | Limited (Max ~12-15 ft safely) | Variable (Depends on build) |

| Labor Cost | Low (Fast completion) | High (Slow progress) | High (Assembly labor required) |

Elevate your Scissor Lifts for Festive Lighting with Occupational Safety

With a better knowledge of lifts and aerial work platforms, you can ensure that the role of scissor lifts in festive lighting installation becomes a more significant factor in your decor project.

In order to have a high level of safety in your decorative work, it is a must that you follow safety rules to the letter, and this is not just for your safety. Cold weather usually comes with the festive season and with that there is wind and ice and which may be slippery surfaces and all these things cause risks.

The operators have to be made aware of and trained on the appropriate use of the particular type of lift they are going to use either by renting or buying. One very common accident amongst the community of these operators is the overturning of the lift which happened when the machine was being moved on uneven lands and the wind blowing.

Therefore, the operator must not only know the limits of the device but also be closely monitoring their lift conditions and surroundings during work to prevent tipping accidents.

In addition to being initially trained and familiar with the equipment and the site, the installers have to perform a site hazard check every time they use a specific location for their work.

In essence, this means that they have to walk through the area of their work and assess the conditions and the environment for potential hazards and risks that can cause serious injuries should they be ignored.

This extends to checking the area around power lines which are a significant hazard when you consider that the people will be working with electrical holiday lights. Keeping power lines at a safe distance is also very important. Additionally, you should ensure that the surface is suitable for the tires of the lift you intend to use.

- Overhead Hazard Checks: Before using any sort of an aerial work platform, it is vital to first check and survey the ceiling or the sky in order to be able to spot beams, sprinklers, and especially power lines, which always call for special caution where electrical devices are concerned.

- Fall Protection: Even if the scissor lift comes with guardrails it would be advisable to wear a great harness that is well connected to an anchor point of the platform via a lanyard.

- Wind & Weather: When the installation is outdoors, one should keep in mind that a scissor lift should never be operated in wind speeds of more than 28 mph (approx. 12.5 m/s), and platform floors where the lift is used must always be kept free of ice and snow.

How to select the Role of Scissor Lifts for Festive Lighting for indoor and outdoor lighting projects

Don’t think all lifts have the same characteristics, a totally different brand and model may feature capabilities with varying performance levels as well as differing additional functionalities.

Choosing the most appropriate machine will also be an important factor that will determine whether you will have a successful project or not. The use of electric scissor lifts is generally predicted for use inside the buildings i.e. malls, hotels, or office atriums.

They are battery-operated, and hence save the environment completely. Plus they are almost noiseless, which is of great value when you are working in confined spaces within the eated public areas. More importantly, they come fitted with tires that do not leave black marks on the marble, or tiled floors or any other costly flooring.

On the other hand, if you are thinking of giving your city the Park lights, it is time to call for a rough terrain scissor lift. Such lifts usually run on diesel or dual fuel engines (though an electric rough terrain model is available too) and are equipped with heavy-duty, foam-filled tires approved for use on gravel, grass, and uneven pavements.

Most of these machines also have built-in outriggers (which are basically stabilizers) that help keep the machine horizontal on sloped ground, thus ensuring your safety as you go up a tall building for the facade lighting installation.

- Indoor Projects: Use Electric Scissor Lifts (19ft to 32ft) with non-marking tires to protect flooring and ensure quiet operation.

- Outdoor Projects: Use Rough Terrain Lifts (26ft to 50ft) with 4-wheel drive and auto-leveling outriggers to handle uneven ground and wind.

- Access Scarcity: If you are looking for a place or space that is extremely narrow and it may be a devoted small area of a store full of retail racks, then “micro,” or vertical mast lifts, which offer a smaller footprint, would be an option for these kinds of situations.

Financial Benefits and Thinking about Rental Options

What most owners of businesses worry about is the cost of a heavy-duty machine, but the reality is that in most instances, the cost of using a scissor lift for festive lighting will be at the very least, reduced, if not totally wiped out. The math is very straightforward. In commercial decoration contracts, labor is usually the most significant cost.

Therefore, if an installation crew of two, who are working with a lift, are able to deliver a site-ready scenario in one night as opposed to a group of four going slowly and taking three nights with the use of ladders and scaffolding, then even skimping on the hire of a lift will hardly take the blowing up of balloons by your kids in another room for a second.

Moreover, the rental businesses know quite well the holiday season demand surge which normally extends over the period between October-November-December. The advantage of early booking is not only one of security but also one of better rates.

Also considered is the cost-effectiveness of having arranged “weekly” rentals, even if the lift will only be used for 3-4 days, as often the weekly rate is cheaper than the daily cumulative rate. So, if the weather changes or gets bad, or there is an unexpected delay in the installation process, you have a buffer to work with if only your time window is a week-long one.

- Labor Reduction: The speed of a lift can reduce total man-hours by up to 50%, thus lowering the overall project cost significantly.

- Rental vs. Purchase: For seasonal businesses, renting is practically the most tax-efficient and economical way to operate in the business as opposed to the year-round maintenance of a machine.

- Bundled Logistics: negotiating delivery and pickup fees upfront prevents unexpected charges from eating deeply into the project budget.

FAQs: Role of Scissor Lifts for Festive Lighting

Which scissor lift type is best for indoor Christmas light installation?

A battery-powered Electric Scissor Lift is the best option for indoor use. People prefer these machines because of their zero-emission feature, which makes them non-fume-polluting. They are also extremely quiet and have non-marking tires. In this way, they will not damage your flooring if it is tiled, carpeted, or wooden. The 19-foot or 26-foot models are generally suitable for the indoor malls and lobbies of office buildings.

Do I require a license or certification for the operation of a scissor lift for decorations?

Definitely, most areas (in the US, OSHA being the main authority and, in the UK/India, the equivalent bodies) will require the operators to go through training and be certified before being allowed to operate the scissor lift. Even if it is not necessary for you to get a “driver’s license”, an employer has the responsibility of ensuring that anyone who is to be operating the lift has been through training compliant with ANSI/OSHA guidelines. Instruction for aerial lift operators will consist of control handling, safety inspections, and hazard awareness/avoidance.

How much average load weight can a scissor lift support during a lighting setup?

Depending on the model, the carrying capacity of the scissor lift will be different. However, most standard 19ft to 32ft scissor lifts can hold between 500 and 1,000 lbs (227 kg to 454 kg). This is the maximum weight allowed by an operator including a combined weight of the tools and lighting equipment. As a matter of safety and care, one should always check the machine data plate before loading.

What height can a scissor lift reach to hang lights?

Typically, scissor lifts have a working height range from about 19 feet up to 53 feet. If you need to work at a height that is beyond 50-60 feet or want to reach over an obstacle such as a fountain or grand staircase, then getting a boom lift (cherry picker) might be a better choice than getting a scissor lift since they only move up and down vertically.

Does one need to wear a safety harness while using a scissor lift during holiday decorating?

Yes, not only should it be highly recommended but, it is required by law in many areas. Although there are guardrails around a scissor lift, a fall arrest system consisting of (full-body harness and a lanyard) attached to an anchor point on the platform, is implemented for added safety. This prevents the danger of being forcibly ejected from the basket in the event of a vehicle crashing into the lift or the operator landing on shaky ground.

What is the going rate for a scissor lift rental during the holiday season?

Rental costs vary by location and machine size. On average, a standard 19ft electric scissor lift rents for approximately $100-$150 per day or $250-$400 per week. Rough terrain models are more expensive. Due to high demand during the holiday setup season (Oct-Dec), prices may fluctuate, so booking weeks in advance is advised.

Happily, Choose the Role of Scissor Lifts for Festive Lighting:

The role of scissor lifts for festive lighting installation has become chiefly associated with modern professional Xmas and New Year’s displays. Draping the facade of a commercial building with icicle lights or decorating the grand Christmas tree in a hotel lobby, the use of these machines brings in a level of safety, speed, and stability beyond what ladders can offer.

When it comes down to it, equipping yourself with the right gear no matter if it’s an electric machine that operates silently and efficiently indoors or a dirt track animal that can handle the outdoors -you are still guaranteeing the safety of the people who will be responsible for creating holiday magic.

For the next festive season, consider integrating aerial work platforms into your decoration strategy, scissor lifts for festive lighting is not only a smart choice, it is the industry standard for excellence.