Mastering Elevation: Your Complete Guide to a Scissor Lift for a Sloped Floor

Ground irregularities and other terrain factors are some of the few problems that may crop up during construction as well as facility maintenance works. The problem of access to vertical equipment arises when the contractors and operators come across an uneven ground, ramps, and inclines. Thus, comes the solution in the form of “Scissor Lift for Sloped Floor.”

The use of a scissor lift for a sloped floor entails a different manner of operation since the standard slab scissor lifts are engineering wonders almost solely planned to be used on flat, hard, and even surfaces. Any unit used on an incline may set the tilt sensors that disable the lifting mechanism or, even worse, result in fatal tip-over accidents.

However, the rough terrain versions and specific safety measures to handle a slope without compromising the machine’s stability and to achieve the goal safely and efficiently must be employed by industry professionals.

Importance of Scissor Lift for Sloped Floor:

The solution that comes to mind first in such cases is the Rough Terrain (RT) scissor lift that is the kind of equipment that is expected to solve the problem of a scissor lift for sloped floor. However, this can be only a rough first guess as, apart from the pneumatic tires, RT lifts may be powered by heavy-duty internal combustion engines (diesel or dual fuel), or high-power electric drive systems.

Such features like aggressive tread tires, oscillating axles, and especially hydraulic outriggers, are the main difference of these machines from indoor electric ones. These machines don’t just “cope” with slopes; they are built to dominate them, making workers’ access to the required heights possible even if the ground is slanted.

- Standard Limitation: Generally, indoor lifts are equipped with pothole protection and have low ground clearance making them incapable of climbing slopes over 25% physically.

- Tilt Sensors: Nowadays, lifts have tilt sensors (inclinometers) that limit the angle of the slope to 1.5 to 3 degrees above which further lift ections are denied to the machine. Besides, the sensors disable lifting when the machine reaches a certain slope while the platform is elevated.

- The RT Advantage: In contrast to regular terrain models, rough terrain equipment most probably has a gradeabiliy of 35% to 50%, thus, it is capable of climbing steep ramps to reach the working area before leveling out for the lift.

The Impact of Outriggers and Stabilizers is Unquestionable

One of the main factors that determine the success or failure of a scissor lift run on a sloped floor is undoubtedly the leveler outrigger system since without it they are still only machines trying to balance on the slant.

No doubt such a consideration just like safety measures and training for the use of the equipment are among the reasons why the market keeps offering outriggers as add-ons with various scissor lifts.

A scissor lift can be limited in operating on sloped places as the chassis gets tilted and outriggers can be used to level the scissor lift out of the sloping surface.

Outriggers are not only great for effect, but they are essential when it comes to the fact that they can transfer heavier loads to a larger, crisper surface which helps prevent sinking, tipping, and other weak spot related issues.

Additionally, they serve a structural purpose that is crucial, quite apart from the role of stability, in fact, lifting on any significant grade without them is practically impossible. Deployment of outriggers during scissor lift for sloped floor helps in displacing the load due to the machine and payload from the tires, which usually undergo compression and shifting, to the solid steel legs.

Thus, a wide, rigid footprint which resists wind forces and dynamic loads caused by workers moving on the platform is created. However, operators must remember to ensure that the ground under the outrigger pads is capable of withstanding the pressure; otherwise, the use of spreader pads is recommended to avoid the ground giving way to a prone tilt situation.

- Auto-Leveling: More advanced and sophisticated are systems that use auto-leveling where each leg is adjusted independently for proper leveling of the terrain.

- Load Distribution: Outriggers redirect the point loading from the tires thus, preventing user’s “bouncing” or tire sidewall collapse during operation.

- Interlocks: Interlocks are set in place to guarantee that the platform will only be raised when all the four outriggers are firmly planted and the chassis is level.

Gradeability and Operating Slope: A necessary distinction

Choosing a scissor lift for sloped floor without knowing the exact meaning and difference of gradeability and operating slope will lead to the wrong decision and the wrong equipment. Gradeability has to do with the capability of the machine to drive up an inclined way when in its stowed (lowered) position.

A 40% gradeability system means doing the lift up a very steep ramp leading to a job site. On the other hand, such a machine cannot just extend the platform while sitting on that 40% slope. The maximum angle or operating slope at which the lifting can take place is usually very low, close to zero unless the machine is leveled using outriggers.

A confusion of these two parameters results in dangerous consequences and severe accidents. As a project manager, before deciding on using a scissor lift for sloped floor, you need to have a gradient measurement of the site.

If the slope is only meant for the lift to be driven from location A to location B, then only the gradeability spec needs to be checked. But if the work is to be performed on the slope (such as changing a ceiling light above a ramp), then a machine is a must with auto-leveling outriggers or bi-leveling track system.

Bi-leveling or self-leveling crawler lifts are an innovation whereby the tracks adjust independently to the contour of the ground thus, the chassis remains level while the tracks move along the slope, and “drive-at-height” becomes possible even on uneven ground.

- Gradeability: It is a percentage number that indicates the steepest hill the machine can climb while stowed (e.g., 40% grade).

- Slope Rating: It is the maximum angle (in degrees) the chassis can tolerate before the tilt sensor disables the lift function (usually < 3 degrees).

- Calculation: Grade is derived from formula (Rise / Run) × 100. A 45-degree angle corresponds to 100% grade.

The Special Equipment: Bi-Leveling Crawler Lifts – Scissor Lift for Sloped Floor

When you want to perform delicate maneuvers in a scissor lift for sloped floor – a tough spot for a RT one, where one has to deal with a slippery mud mixture on a slope, for instance – the choice of crawler lifts (or track lifts) becomes a definitive answer.

Tracked loaders make up one group of heavy construction equipment with continuous tracks instead of wheels, the most popular examples being the tank and excavator.

Broadly speaking, the massive surface area of the tracks decreases the ground pressure and, thus, the lift is not allowed to get stuck in the soft ground. The important point is that a few “bi-leveling” models that have a dynamic structural design can tilt the entire chassis independently of the track base.

Therefore, the tracks may be on a 20-degree steep incline while the scissor stack and platform would still be perfectly vertical and level, without the need to stop and deploy static outriggers.

Going forward, this invention has made a scissor lift for sloped floor a matter of time and energy. A conventional rough terrain lift requires the operator to drive, stop, and set the equipment through a series of steps before being able to lift.

On the other hand, a bi-leveling crawler lift can drive with the platform elevated (within safety limits) thereby enabling jobs such as tunnel maintenance, pruning, or painting along a sloped retaining wall to be finished within dramatically reduced cycle times.

Being more expensive to rent, these units will still be profitable through the labor hours, safety, and other benefits that they bring along.

- Dynamic Leveling: While the machine is moved over changing terrain, the chassis actively adjusts itself to stay level.

- Low Ground Pressure: Tracks spread out the weight over a very large area which is perfect for landscaping or delicate surfaces that are also sloped.

- Agility: Usually, these machines can turn in place (zero radius) which makes them ideal for narrow and sloped worksites.

Safety Rules for Operating on a Scissor Lift for Sloped Floor

Using a scissor lift for sloped floor safety always comes first. The force necessary to raise a 2,000-pound platform 40 feet up will drastically shift the center of gravity. When the machine is positioned on a slope, the “tipping line” or, in other words, the line after which the machine will topple, becomes significantly shorter.

Therefore, pre-start inspections have to be thorough, and operators should check the condition of the tires (if the unit is wheeled) since a flat tire can cause an artificial tilt. Moreover, the operator must check the hydraulic lines to the outriggers, since a leak here could cause a leg to collapse under load and result in a tip-over.

Besides that, one must always review the ground conditions visually as well as by probing to confirm that there are no backfilled trenches or covered holes, which may give way under the intense pressure of an outrigger pad.

The way an operator behaves using a scissor lift for sloped floor must be changed too. Movements are to be kept slow and deliberate. When driving a stowed machine on a slope, an operator must keep the heaviest side of the machine (usually, the engine compartment or battery pack) uphill side if at all possible or follow the manufacturer’s specific instructions for ascending or descending.

Turning the machine 90 degrees on a steep slope should never be attempted, as this exposes the machine of a tipping point axis. The way to approach the slope incline is either up or down. A move to flatter ground should be made if the tilt alarm goes off. If the platform is elevated, this must be lowered first.

- Perpendicular Approach: Ramp shouldn’t be used for driving across a slope but to go straight down/up. Driving across a slope is a sure way of # increasing rollover risk.

- Ground Assessment: Make sure that the soil underneath the outrigger pads is compacted and stable either by sight or using a probe.

- Rescue Plan: It is imperative to have an assistant on the ground who you must know how to lower the machine should it be stuck at height on a slope.

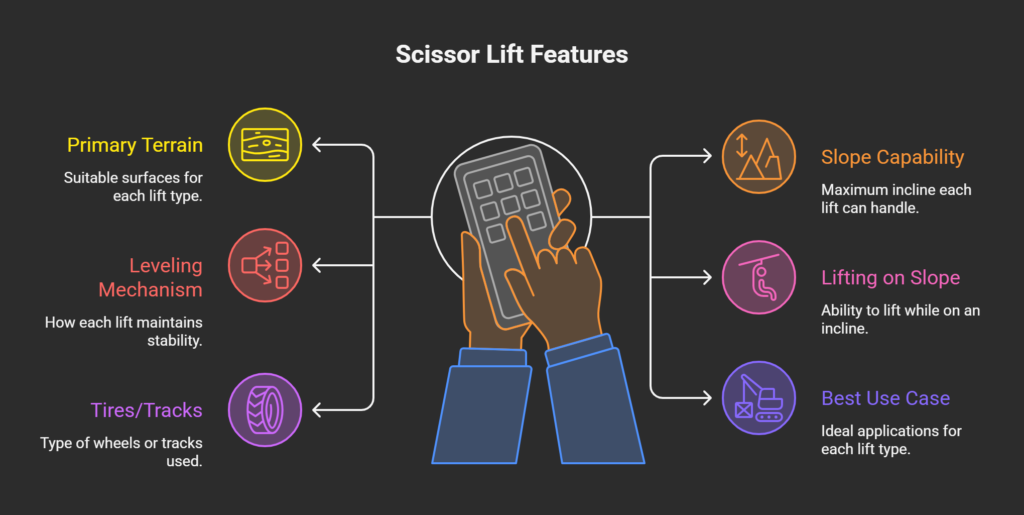

Types of Scissor Lifts vs. Their Performance on Sloped Terrains

To help you select the machine that suits your needs the best, below is a comparison of the three primary categories of lifts in terms of their suitability for a scissor lift for sloped floor application.

| Feature | Slab Scissor Lift (Electric) | Rough Terrain (RT) Scissor Lift | Bi-Leveling Crawler Scissor Lift |

| Primary Terrain | Flat concrete, smooth indoor floors | Dirt, gravel, uneven outdoor ground | Mud, steep slopes, delicate turf |

| Slope Capability (Driving) | Very Low (< 25% Gradeability) | High (30% – 50% Gradeability) | High (Variable, excellent traction) |

| Leveling Mechanism | None (Pothole guards only) | Hydraulic Outriggers (Manual/Auto) | Dynamic Self-Leveling Chassis |

| Lifting on Slope | NO (Must be on flat ground) | YES (Once leveled by outriggers) | YES (Can drive while elevated on slope) |

| Tires/Tracks | Solid, smooth non-marking | Pneumatic or foam-filled lug tires | Continuous rubber tracks |

| Best Use Case | Warehouses, Malls | Construction sites, Exterior cladding | Tunnel work, Hillside landscaping

|

Frequently Asked Questions about Scissor Lifts on Sloped Floors

Is it possible to use a scissor lift on a slope?

The answer is, yes, but only to certain models. Generally, a slab type of scissor lift is not suited for slopes as it doesn’t have the capability to level itself. On the other hand, RT scissor lifts that come with outriggers (stabilizers) or bi-leveling track lifts such as the ones used in construction are capable of doing this. The mentioned models are equipped with features that allow them to level the chassis prior to platform elevation.

How steep a slope scissor lift can handle?

Rough terrain (RT) machines can go anywhere from 30 to 50% grades when in the stowed (drivable) position. The chassis needs to be almost flat (within 1.5 to 3 degrees) during lift extension most of the time. In the event that there is a greater slope that the chassis is on, the outriggers have to be deployed first to level the machine.

What does ‘gradeability’ mean when talking about a scissor lift?

Gradeability refers to the maximum steepness that such a machine can handle when it is in its stowed or fully lowered state. A corresponding gradeability value is thus a percentage. In other words, a 40% gradeability means you can climb up 4 feet of vertical rise over a 10-foot horizontal distance. However, this figure gives no indication of the kind of slope the machine can raise on.

What is the formula for determining the grade of a slope?

The grade percentage can be figured out using the formula: (Rise / Run) x 100. For example, if a ramp elevates 2 feet (Rise) with a horizontal run of 20 feet (Run), then the grade will be (2 / 20) x 100 = 10%. For quick measurements, you can also rely on digital inclinometer applications available on smartphones.

Why is the scissor lift unit refusing to function on a slope?

The reason for this is a safety feature. There is a tilt sensor (inclinometer) inside a scissor lift that disconnects the power to the lift once it detects that one side of the equipment is already at an angle bigger than the one set by the manufacturer. Therefore, you either have to level the chassis with outriggers or move the machine to a flat area in order to continue the operation.

Do scissor lifts come with a braking system?

Yes, scissor lifts come fitted with safety brakes. On electric variants, they usually operate as electromagnetic parking brakes that engage automatically the moment the joystick is released. Service brakes as well as parking ones are featured on rough terrain (RT) models to ensure safety during slope transport and operation of such heavy mobile units.

What are the safety instructions when operating a scissor lift on a slope?

The safety recommendations pertain to the following:

- Conduct a thorough inspection of the ground condition before setting out the outriggers.

- Develop an emergency plan to execute safe rescue.

- When the platform is still at an elevation, lower it immediately once the tilt alarm goes off.

- Movement in the up and down directions only on a slope, no sideways motion.

- During rough terrain travel, securely fasten all the loose items in the platform.

Wrap up – Scissor Lift for Sloped Floor

Using a scissor lift for sloped floor is a tough challenge but not beyond the help of the right machine and its proper handling. While experiments by the man of physics tell us that elevating heavy loads on a slant is a risky and challenging activity, technology by the engineers offers us solutions in the form of Rough Terrain and Bi-Leveling scissor lifts.

Accurate knowledge, safety awareness, and a positive attitude on the part of the operators help to turn a difficult and undulating jobsite into a piece of cake. To make a long story short, when the tilt alarm goes off, please, respect the machine by lowering the platform and figuring out how to make up ground on a level spot before continuing with the work.