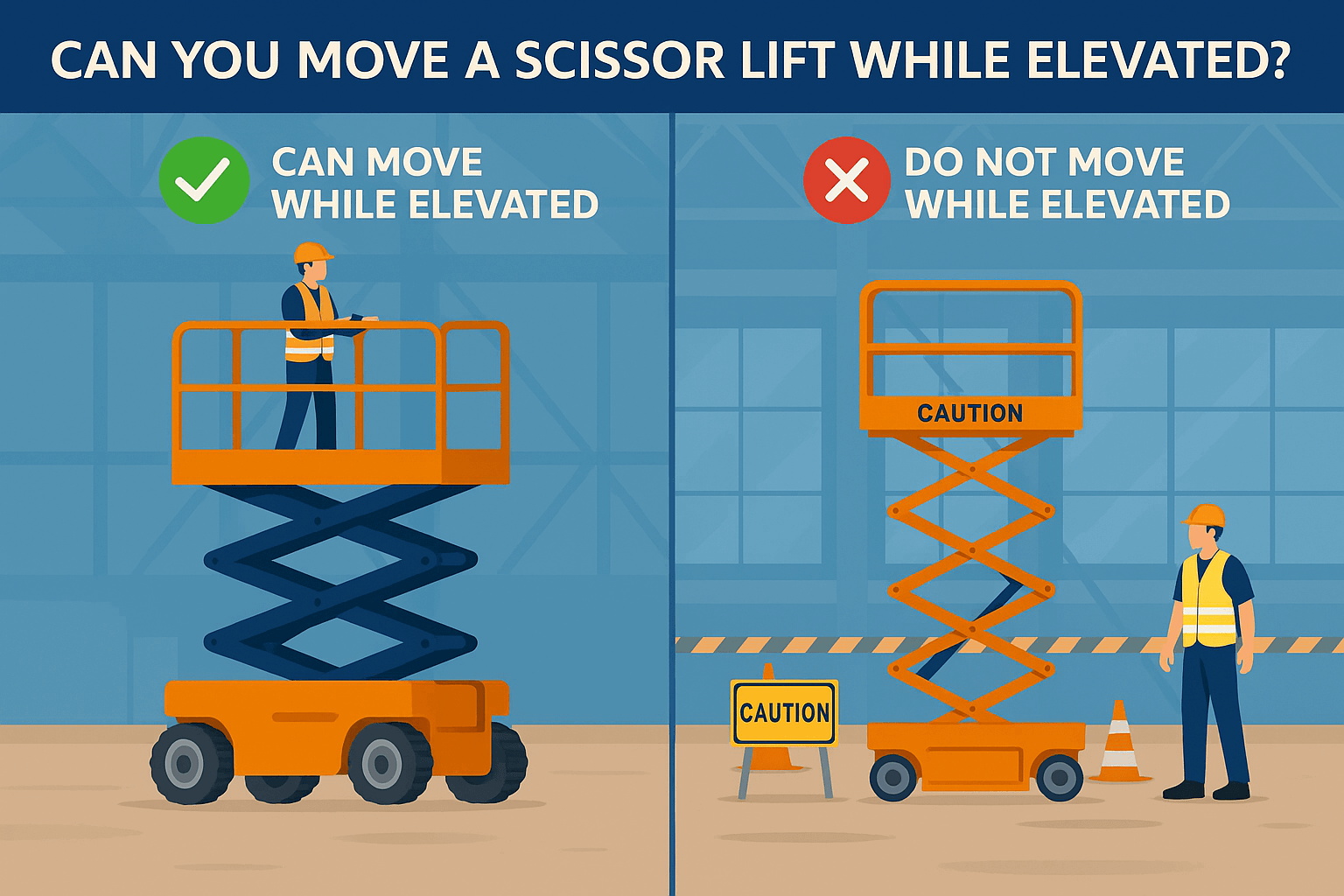

Yes, it is sometimes possible to move a scissor lift while elevated, but it depends on the model, manufacturer’s guidelines, and strict adherence to safety rules. Self-propelled scissor lifts are specifically designed for this purpose within designated height and terrain limits, while push-around models must always be lowered before moving.

Can You Move a Scissor Lift While Elevated?

Introduction

Scissor lifts are specialized machines used in construction, maintenance, and warehouse operations to lift workers and materials to elevated work areas safely. An important question often asked is: can you move a scissor lift while elevated? Understanding the answer is essential for site safety and productivity.

Meta Description: Learn whether you can move a scissor lift while elevated. Understand safety guidelines, lift types, and best practices in this complete guide.

Types of Scissor Lifts

Scissor lifts come in two main categories: self-propelled and push-around, each with its distinct safety considerations and mobility features.

-

Self-Propelled Scissor Lift: Equipped with built-in drive systems, these lifts can be driven around worksites even when slightly elevated, subject to manufacturer specifications and safety restrictions. They are ideal for tasks that require frequent repositioning, such as electrical installations or maintenance work.

-

Push-Around Scissor Lift: These units must be manually moved when not elevated. They are designed for simple up-and-down tasks, and moving them while raised is both dangerous and prohibited by the manufacturer.

Can You Move a Scissor Lift While Elevated?

The main question, “can you move a scissor lift while elevated,” does not have a universal answer and depends on the model.

- Many self-propelled scissor lifts, including both electric and rough terrain models, are designed to be safely moved while the platform is raised—but only within specified height limits. Typically, maximum drive heights are much lower than the maximum lift height, often capped at 1–2 meters.

- Push-around models should never be moved when elevated.

- Safety features such as automatic brakes, tilt sensors, load sensors, and pothole protection are integrated into self-propelled lifts to minimize risk when moving while raised.

- Moving a scissor lift when elevated should always be slow and deliberate, with the operator fully aware of ground conditions.

OSHA Guidelines and Safety Considerations

OSHA and ANSI standards emphasize following manufacturer instructions regarding elevated movement of scissor lifts. General guidelines include:

- Do not move a scissor lift when elevated unless expressly permitted by the manufacturer’s operating manual.

- Operator training is mandatory for anyone using scissor lifts, covering safe movement, pre-use inspections, and hazard identification.

- Adequate guardrails must always be in place, and personal protective equipment (PPE) may be required, especially at elevated heights.

- Moving a lift while raised should never be performed on slopes, uneven terrain, or near hazards such as overhead power lines.

- Never allow untrained workers to operate or relocate a scissor lift, whether it’s self-propelled or push-around.

Real-World Use Cases

There are legitimate scenarios where moving a scissor lift while elevated is both useful and necessary:

- Warehouse Operations: Operators frequently reposition self-propelled scissor lifts at moderate heights to install lighting, perform inventory work, or make repairs across large, smooth-floor warehouses. Advanced safety controls and defined driving-height limits make this routine safer.

- Construction Sites: On construction sites, rough-terrain self-propelled lifts may be repositioned at partial lift height for tasks such as overhead duct installation or exterior facade work. Operators must ensure ground stability and strictly follow safety protocols to prevent tip-overs or falls.

- Restricted Access Areas: Moving the lift slightly raised can save significant time by reducing the need to lower and reposition for every small movement.

Conclusion

- Self-propelled scissor lifts can be safely moved while slightly elevated if the manufacturer allows it, and all safety protocols are followed.

- Push-around scissor lifts and any lift outside the permitted drive height must not be moved while raised.

- OSHA and ANSI standards reinforce strict operator training, adherence to the owner’s manual, and use of all safety features.

- Always prioritize a safety-first approach: if in doubt, lower the platform before moving.

Best safety features to look for when moving a scissor lift raised

When moving a scissor lift while raised, it’s crucial to ensure several safety features are active and properly maintained to minimize risks for operators and surrounding workers.

Key Safety Features to Look For

- Guardrails on Platform: These are the primary line of fall protection. Always check for a complete guardrail system with top, mid, and toe boards before operation.

- Tilt and Overload Sensors: Advanced lifts have sensors that warn or automatically restrict movement if the platform is not level or if load limits are exceeded, helping prevent tip-overs.

- Emergency Lowering Systems: Allows the platform to be lowered quickly in the event of malfunction or dangerous situations, protecting occupants during unforeseen incidents.

- Automatic Braking/Drive Speed Limiter: These features limit the lift’s speed when the platform is elevated, preventing sudden, unsafe movements and maintaining stability (e.g., below 0.5 mph as per Genie GS-1930 manual).

- Non-Slip Platforms: Reduce the risk of slips and falls when working or moving the lift.

- Wheel and Tire Condition: Properly inflated and well-maintained tires are essential, especially when driving while elevated.

- Pre-Operation and Functional Controls Check: Always verify that all controls (raising, lowering, drive, brakes) and emergency stops are fully operational before starting work.

- Spotters and Clear Signaling Procedures: Having a trained spotter to guide the operator, especially in tight spaces, dramatically reduces the risk of collision or tip-over.

- Level and Stable Operating Surface: Only move the lift on smooth, flat, stable surfaces, after verifying that no obstacles or overhead hazards are present.

Proper training, regular inspections, and systematic use of these features are fundamental for safely moving a raised scissor lift.

How to train operators to move scissor lifts safely while elevated

Training operators to safely move scissor lifts while elevated requires a structured program combining OSHA-compliant classroom instruction, hands-on practice, regular evaluations, and ongoing reinforcement.

Core Steps in Operator Training

- OSHA-Approved Training: Only qualified trainers should deliver instruction, using updated, OSHA-compliant materials covering all lift types, workplace hazards, and emergency procedures.

- Hazard Recognition: Train operators to identify hazards such as unstable surfaces, overhead obstacles, pedestrian traffic, and electrical lines before moving the lift while raised.

- Manufacturer Guidelines: Emphasize the importance of following manufacturer-specific guidance regarding maximum travel heights, speed, and safe terrain for elevated movement.

- Safe Operation Skills:

- Demonstrate and practice slow, controlled movement when the lift is elevated.

- Teach how to keep loads balanced and secured, and how to ensure clear paths free from hazards, debris, or bystanders.

- Cover proper use of controls, emergency modes, and interpretation of alarms, tilt indicators, and safety sensors.

- Use of Spotters and Communication: Include training on using spotters and hand-signals or radios in congested work zones or limited-visibility situations for additional safety.

- Personal Protective Equipment (PPE): Mandate PPE use, such as harnesses if required as per jobsite risk assessment, and stress platform guardrail rules.

- Evaluation and Recertification: Conduct written and practical exams, with periodic refresher training at least every three years or when equipment or workplace hazards change.

Comprehensive training that combines these elements helps operators remain safe and confident when moving a scissor lift while elevated, meeting both legal requirements and industry best practices.

Create a step-by-step training module for moving lifts while elevated

Here is a step-by-step training module designed for instructing operators in the safe movement of scissor lifts while elevated. This curriculum ensures OSHA compliance and focuses on hazard mitigation, hands-on evaluation, and safety responsibilities.

Step-by-Step Training Module: Moving Scissor Lifts While Elevated

Module Overview

- Objective: Train operators to move self-propelled scissor lifts safely while raised, as permitted by manufacturer guidelines and site protocols.

- Audience: Certified personnel, site managers, safety supervisors.

1. Classroom Instruction

OSHA & Manufacturer Guidelines

- Review OSHA 29 CFR 1926.453 and ANSI A92 standards.

- Emphasize that only self-propelled lifts are designed to be moved while elevated and always within specified height and speed limits.

- Discuss dangers: tip-overs, crushing, electrocution, and falls.

Pre-Shift Requirements

- Checklist review for inspections, including safety features (tilt sensor, brakes, guardrails).

- PPE requirements: Hard hat, harness (if required), safety vest, footwear.

2. Hazard Recognition & Area Preparation

Site Assessment

- Identify overhead obstructions, uneven/slick surfaces, and hazards (debris, open trenches, traffic).

- Confirm work area cordoning; use barricades and warning signage.

- Assign a spotter if visibility is limited.

3. Hands-On Equipment Familiarization

Pre-Operational Check

- Inspect controls, alarms, brakes, wheels, and emergency lowering system.

- Confirm platform rails/gate are secure and clear of loose items.

Elevated Movement Practice

- Demonstrate slow, precise driving with platform modestly raised—never exceeding manufacturer’s travel height limit.

- Practice stopping, steering, and hazard avoidance while always monitoring surroundings (up, down, and around).

4. Safe Movement Protocol

Operator Protocol

- Travel only on flat, stable surfaces.

- Before moving: Announce intention, ensure area is clear of personnel, and confirm path is free of obstructions.

- Move in lowest allowed drive speed (many lifts have automatic speed limiters when elevated).

- Never use lift if winds exceed safe limits or visibility is compromised.

Spotter Communication

-

-

Use standard hand signals or radios for coordination if vision is blocked or in crowded work zones.

-

5. Emergency Response Training

Malfunction Procedures

- Practice emergency lowering and stopping procedures.

- Train on handling sudden alarms or platform instability.

- Drill evacuation and first-aid response in case of injury.

6. Written and Practical Evaluation

Knowledge Test

-

-

Written quiz covering safety, regulations, and equipment-specific info.

-

Hands-On Assessment

-

-

Demonstrate all steps under trainer observation: Pre-checks, elevated drive, emergency stop, and proper shutdown.

-

Retraining Triggers

-

-

Any incident, equipment change, or at minimum, every three years per OSHA guidelines.

-

7. Certification and Records

-

Log successful completion and provide operator certification cards, which must be available on all jobsites.

This training framework ensures operators are thoroughly prepared to move scissor lifts safely while elevated, greatly reducing workplace risk and complying with regulatory standards.

What PPE and equipment are mandatory during elevated repositioning

During elevated repositioning of a scissor lift, mandatory PPE and equipment requirements focus on comprehensive fall protection, visibility, impact, and hazard minimization, in line with OSHA guidelines and best practices.

Mandatory PPE and Equipment

-

Guardrail System:

A standard-compliant, undamaged guardrail system must always be installed on the lift platform to provide primary fall protection. Operators must never stand on guardrails or bring additional equipment to increase height. -

Hard Hat:

Required for head protection against falling objects and overhead hazards. ANSI/ISEA-compliant helmets are recommended for industrial worksites. -

High-Visibility Vest or Clothing:

Ensures the operator is easily seen by others working in the area to prevent collision or accidental contact. -

Non-Slip, Steel-Toed Footwear:

Essential for stability and protection from dropped tools or materials. -

Work Gloves:

Provides grip, reduces the risk of hand injuries, and shields against abrasions or cuts. -

Eye Protection:

ANSI Z87.1-certified safety glasses or goggles protect against flying debris, especially in construction zones. -

Personal Fall Restraint System (when required):

OSHA does not universally require a harness when a functional guardrail system is present, but a properly anchored fall restraint (harness + lanyard) may be mandated by site policy, specific lift configuration, elevated risk (e.g. damaged rails), or local regulations. -

Functioning Emergency Lowering Controls & Alarms:

The lift should always be checked for operational emergency systems prior to use for prompt response to malfunctions.

Always refer to the equipment manufacturer’s manual and site-specific guidelines for any additional requirements, and enforce pre-operation inspections of both PPE and lift safety features before every shif