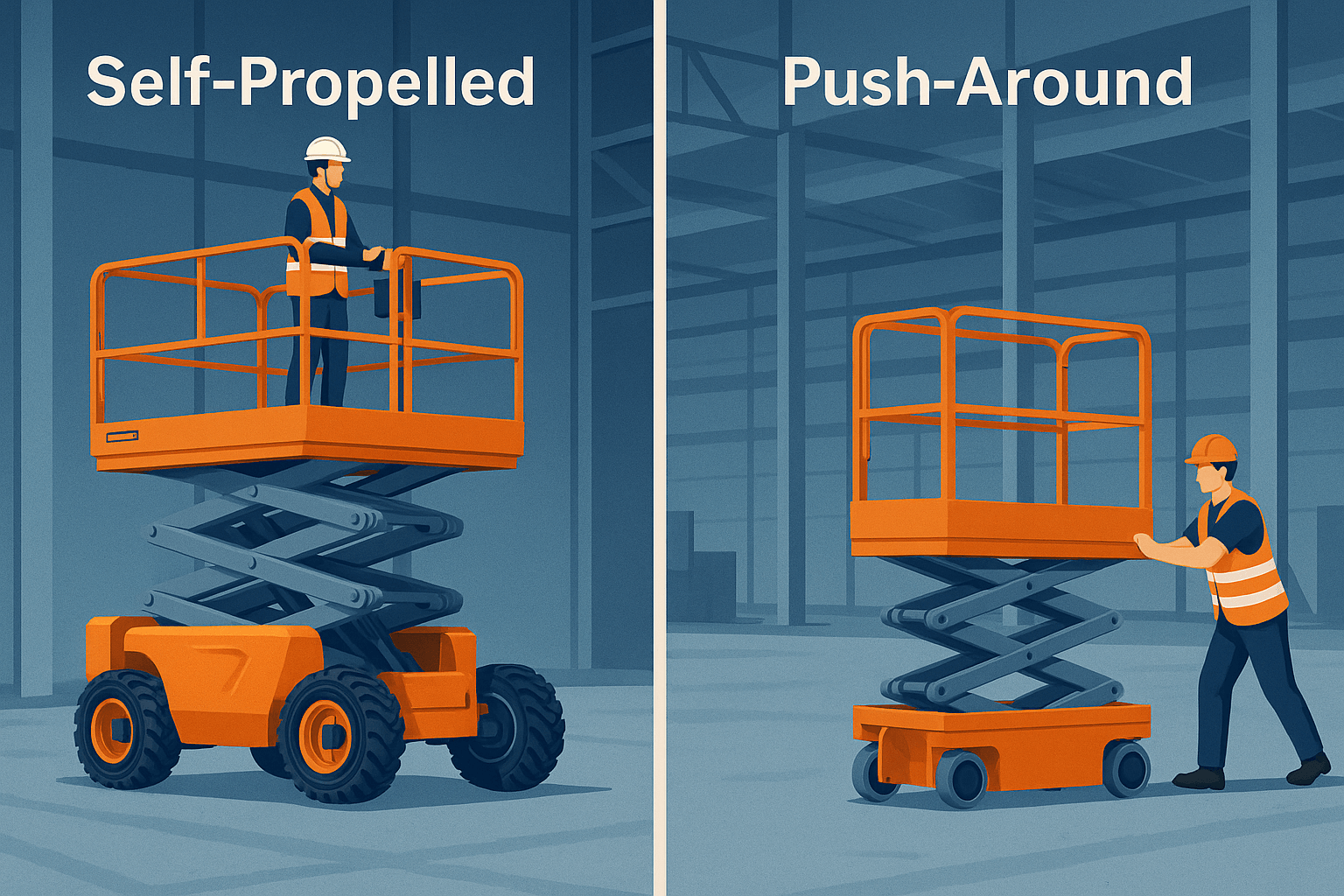

Self-Propelled vs. Push-Around Scissor Lifts: Which is Better for Your Application?

Self-Propelled vs. Push-Around Scissor Lifts: While choosing the appropriate scissor lift for your work-at-height tasks, It is very important to figure out whether a self-propelled scissor lift vs. push-around scissor lift (manually moved) is more of a help for your work. The dissimilarity is not only by cost – it influences safety, usability, efficiency, and the capability of adapting to various job surroundings. In this article, we’re going to look at these two models in detail so you can decide which one fits your application best.

What Are Push-Around Scissor Lifts and Self-Propelled Scissor Lifts?

Before we proceed with the comparison, let’s define the two:

Push-around scissor lifts, also known as manually moved, push-type, or push-around scissor lifts, are those lifts which need an operator (or a small crew) to move them physically. They may be equipped with wheels and thus can be rolled or pushed into the desired location. They usually come equipped with simpler power systems (electric lift, manual push).

Self-propelled scissor lifts are equipped with a drive system that is incorporated into the design, thus enabling the operator to move the lift from the platform (or ground controls), drive along the site under power. They can be electric, diesel, or hybrid, with more features related to power and terrain.

Key Comparison Criteria

These are the most important factors when selecting which model will fit your application best.

| Criterion | Push-Around Scissor Lift | Self-Propelled Scissor Lift |

|---|---|---|

| Mobility / Travel Capability | Must be pushed manually; limited travel; best for short distances on flat surfaces. | Can be driven under power; greater travel distances; better for larger sites. |

| Lift Height & Weight Capacity | Often limited in platform height & load. Good for low-to-medium heights. | Higher platforms, higher capacity; multiple workers + tools. |

| Ease of Setup | Usually simple; fewer systems; lighter — easier to transport or move through doors. | More complex; requires understanding of drive controls; possibly heavier; may need wider doors or ramps. |

| Cost | Lower purchase/hire cost; lower maintenance for drive systems. | Higher upfront cost; higher maintenance costs (motors, batteries/fuel, drive train). |

| Use Environments | Indoor, smooth floors, tight spaces, low reach, occasional use. | Large warehouses, construction sites, outdoors, frequent use, rougher surfaces. |

| Safety & Stability Considerations | Less complex; fewer moving mechanical parts; risk from tipping if load/capacity misused. | More features (e.g. gradeability, onboard safety sensors); but higher risk if used incorrectly (moving when elevated, rough terrain). |

Advantages of Push-Around Scissor Lifts

Push-around scissor lifts have not gone out of fashion and are still used in some situations due to their simple nature and appropriateness for particular environments. Some of the benefits are:

Lower cost

- Lower initial capital or rental cost.

- Lower maintenance on drive or propulsion systems.

- Simpler power requirements (often just for the lift mechanism, not for the drive).

Compactness and portability

- They typically weigh less so it’s easier to transport, take them through doors or put them on trucks.

- Lesser footprint, which is suitable for tight or narrow indoor places.

- The space limitations can be overcome by the folding or telescoping guardrails or the compact design.

Simplicity and fewer components

- Fewer components that may break – fewer moving parts (no drive motors, sometimes no hydraulics for travel).

- Maintenance and repair become easier and also faster.

- Operators get less training as the basic movement is easy either by manual or machine.

Use in situation of intermittent or light work

- Most suitable for jobs which require very rare access to height such as maintenance, lighting and signage indoors.

- It can be used to do the job of cleaning the indoor flat surfaces.

- When the work is done rarely, the operational, and overhead cost become cheaper.

Advantages of Self-Propelled Scissor Lifts

On the other hand, Self-propelled scissor lifts provide a plethora of advantages for heavy-duty, large-area, or regular-time applications:

Enhanced productivity and mobility

- One can go from one place to another by driving thus turning idle time into a productive one.

- By repositioning in a quick way, one saves the time. If there are many tasks that have to be done all over the big area, these savings become a big number.

- Some models, based on safety and design, allow travel while elevated thus creating even more efficiency.

Higher lift heights & load capacity

- Workers, tools, and materials – Can be lifted twice the weight compared to standard single-worch lift. (Lift Sales)

- Taller platforms are accessible, thus better reach. For instance, in huge warehouses, building under the open sky, or the maintenance of large equipment. ()

Better suited for varied and tougher environments

- Some self-propelled units can work on slopes (gradeability), and handle tough ground.

- Braking systems, drive modes, safety sensors, tilt alarms.

- They are indoor and outdoor machines depending on their design.

Improved safety features and operator comfort

- More powerful controls, maybe even control from the platform for moving.

- Better guardrails, and possibly the improved ergonomic design.

- Such features as battery status indicators, emergency lowering, tight stabilization come as a bonus. (MORN LIFT)

Limited reach & capacity

- It is impossible to go up to very high places, and the carrying capacity is lower.

- In a scenario where a lot of heavy lifting or high elevation is required, these lifts do not fit.

Manual repositioning can be inefficient

- Moving the unit by hand will consume physical effort and time.

- If one had to cover a vast area with large work tasks, this activity would slow down operations significantly, as one would have to move back and forth continually, and the pace would thus be affected.

Limited to easy surfaces & indoor use

- The manual movement on uneven surfaces, slopes, and outdoor conditions can be challenging and sometimes even unsafe.

- If the safety issue of tipping or instability occurs and the machine has been used improperly, then it is a cause for concern.

Higher cost (purchase, rental, maintenance)

- Machines of higher value and more complex mechanics.

- The cost of maintenance is higher due to wear and tear of batteries/fuel, motors, and drive systems.

- The need for a facility to refuel or recharge the battery.

Size, weight, transport, and storage problems

- Heavier; thus, larger trucks are required for transportation and stronger floors for indoor storage.

- They may not be able to pass through doorways or fit in tight spaces, which can cause surface damage.

Operator training and safety issues

- Additional controls; the danger is great when the lift is moving and at the same time, it is at a high level; hence, the operator has to be cautious at all times.

- The number of parts that can breakdown is more; hence, it requires thorough and frequent checking and maintenance.

Regulations & standards:

Check local MEWP (Mobile Elevating Work Platform) or aerial work platform standards and safety rules. The majority of the areas set the rules of certified training of machine operators.

- Pre-use inspections: A thorough examination of guardrails, controls, decals; verify brakes and outriggers (if applicable); look for wear or damage is mandatory before use every time.

- Load & capacity limits: Tools or components should not be loaded on machines beyond set maximums; the sum of personnel + tools + materials should be within safe working load.

- Ground & stability: The floor for push-around has to be spot on flat and stable; for self-propelled check grade limits; don’t move if elevated unless the machine is rated for it.

- Training: The operators should have a complete knowledge of both the lift and the driving mechanisms (if applicable); they should also have familiarised themselves with the emergency descent procedure; the route of travel, powering down etc.

Economic Considerations: Total Cost of Ownership (TCO)

While deciding which one is more preferable, a push-around or a self-propelled, it is advisable not to simply rely on a purchase or rental price but to think in terms of the full cost over the lifespan.

Purchase & Rental Costs

- The price to buy or hire a push-around model is relatively low.

- Self-propelled units are more expensive at the beginning.

Operating Costs

- The consumption of fuel or electricity (for self-propelled). The replacement of batteries or the charging of the battery.

- Maintenance & parts: the same components used to power the vehicle, tires, hydraulic systems, etc.

Downtime Costs

- In the case that the machine is relocated frequently, a self-propelled will definitely save the most time.

- On the contrary, a push-around can lead to more waiting time.

Resale / Depreciation

- There is a possibility that self-propelled units become second-hand valuables if good care has been given to them.

- The push-around may have a longer service life if it is made up of simple and less number of parts but the market may be a small one.

When Push-Around Is the Better Choice

These are cases where a push-around is the better choice:

- Jobs performed in facilities with smooth, strong flooring; tight aisles, narrow doorways.

- Works with budgets or rental constraints; small businesses that do not require high productivity or speed.

- Places where simpler safety features are sufficient; minimal travel distances.

- Those works that are relatively low height (< ~6-8 m or so, depending on local units) and infrequent, e.g. changing lights, switches, small maintenance works.

When Self-propelled scissor lifts Make Financial Sense

Below are instances in which a higher expenditure on Self-propelled scissor lifts results in returns worth the investment:

- The works that have several locations on one site and thus the lift needs to be frequently repositioned.

- The outdoor works that can be uneven in terms of terrain or slope or there are obstacles in the way.

- The works that require more height or more load (tools, materials, multiple workers) than a certain limit.

- The places where the speed of work and the productivity are important, e.g. large warehouses, industrial facilities, construction.

Choice Tips: How to Decide for Your Particular Use

Here is a list of questions that can help you decide between these types of vehicles, adapted for your specific use:

- Assess height and load needs: What is the maximum working height? How many people and what tools/materials will be on the platform?

- Consider workspace & terrain: Indoor vs. outdoor? Floor strength, access via doors, ceiling height.

- Surface condition: flat and smooth vs. rough/uneven/slope. Calculate frequency of movement / task spread: If you are going to move the lift frequently between different spots, a Self-propelled scissor lifts probably will save your time. On the other hand, if it is going to be at one location most of the time, then a push-around lift might be enough.

- Budget & Operating Cost Analysis: Look at the buying/renting costs side-by-side along with the ongoing operating, maintenance, fuel/battery costs. Also, think about transport, storage, and training.

- Safety & Regulatory Requirements: Are there any site or region requirements (MEWP legislation, OSHA, etc.) for drive-on lifts?Make sure the following features are there: emergency lowering, tilt sensors, guardrails, stable outriggers or base support.

- Resale / Long-Term Value: If you are thinking of keeping the lift for a long time, then maintenance support, parts availability, and resale value become the factors that matter most.

Summary

Both types of scissor lifts–push-around and self-propelled–are equipment to be found in different scenarios. The determining factor of which one is “better” is your use case:

If it is just about lifting to a low height, working in tight spaces, and only an occasional use, then a push-around lift will probably provide you with sufficient performance at a lower cost.

If it is the case that the lift will be used frequently, the need will be for a higher reach, heavier loads, outdoor, or a large indoor space, then a Self-propelled scissor lifts will likely result in more excellent safety, productivity, and time-saving, although the initial purchase and operating costs will be higher.

The choice of the correct model type is about balancing safety, cost, usability, capacity, and terrain. A needs analysis based on the checklists provided above will make your decision easier.

Can a push-around scissor lift be used outdoors?

Yes, but with limitations. Push-around scissor lifts are suitable mainly on flat, stable surfaces. They might be unsafe or hard to move if the terrain is uneven, rough or sloped. Additionally, the wind and weather conditions may affect the stability of the lift.

Is it safe to drive a Self-propelled scissor lift when elevated?

Only when the specific model is designed and certified for such use. Most Self-propelled scissor lifts hold movement when elevated due to the risk of tipping. Therefore, it is advisable to check the manufacturer ratings and safety guidelines.

What is the typical working height for push-around scissor lifts vs Self-propelled scissor lifts?

The working height for push-around scissor lifts are generally lower (often up to ~20 feet / 6-8 m depending on the region; specific models may differ). Self-propelled scissor lifts are capable of reaching heights much higher – 30-50 ft or more (or even higher in large industrial/outdoor models).

How do maintenance costs compare?

Push-around scissor lifts: lower maintenance (less mechanical complexity, simpler power systems). Initiatives aimed at increasing self-propelled maintenance costs are mainly due to the production of electric motors/fuel cells, battery/fuel, transmission, more parts subjected to wear and tear. Yet, the frequent use can be an explanation of those costs via higher productivity.

What about lift capacity (weight load) differences?

Self-propelled scissor lifts are typically capable of hauling more weight, thus enabling a safer working load plus the tools and materials for work. Push-around scissor lifts have a lower load due to the design of the structure and the limitations affecting stability.

How important are the floor condition and environment?

Very important. Smooth, flat indoor surfaces are perfect for push-around models. If floors are fragile, doors narrow, or ceilings low, then small-sized models (often push-around) are more suitable. In case of rough terrain or outdoor, self-propelled units that are designed for such areas are the only ones that can be used.

What rental vs purchasing considerations should I keep in mind?

If you are using it only a few times or just once, then renting a machine (push-around scissor lift or self-propelled scissor lift) will be more economical. If the usage is regular/weeks and long-term, then purchasing might be better. Besides that, depreciation, resale value, and the total cost of ownership: purchase + maintenance + storage + training vs rental fees should also be considered.