Introduction to Scissor Lift Parts

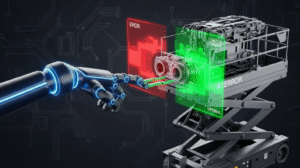

A scissor lift is just a small and light machine with a lot of power, but it works seamlessly with the help of carefully engineered parts, each one doing its particular job.

Every part—from the solid base to the hydraulic system—is indispensable in giving off the safety, sturdiness, and good performance that a scissor lift is known for. Not only mechanics and engineers can gain from the knowledge of scissor lift parts, it is also worth for operators, safety officers, and business owners as well.

Simply put, a scissor lift is a human body: the base and chassis are the legs providing stability, the scissor arms are the muscles that expand and contract, the hydraulics are the heart giving the power, and the control system is the brain sending the orders. If one part gets damaged, the rest of the system may also be affected.

Here we are, going through and talking about every major scissor lift parts, their working principle, common issues, and maintenance tips. By the end of the discussion, you will have a detailed knowledge of the smooth performance of a scissor lift.

Why Understanding Scissor Lift Parts is Important

The knowledge about scissor lift parts is not only just technical—it is also practical. Here are the reasons:

- Safety – Identifying parts that are worn out or even broken can eliminate the possibility of accidents.

- Efficiency – Operators who are familiar with the parts of their machine can easily fix the problem without wasting a lot of time.

- Cost Savings – It is more affordable to replace a small worn component than wait for a major breakdown.

- Confidence – A well-maintained machine and regular checks increase operator confidence when working.

- Satisfaction – Knowing that your equipment will perform reliably makes the working environment less stressful.

What are the Major Scissor Lift Parts?

So, what are the scissor lift parts that make the device function?…

- Compliance – Industries are required to adhere to safety regulations, which in most cases require regular part inspections.

For instance, a leaking hydraulic hose can reduce the lifting capacity or cause sudden drops both of which are quite hazardous. By identifying the problem early really, you let the machine work safely and avoid paying for expensive repairs.

Overview of How Parts Work Together

The scissor lift is a marvel of its parts that are seamlessly integrated.

- The base and wheels are responsible for stability and mobility.

- One can see the wood and the hammer in the scissor arms, as they expand and contract are guided by hydraulic cylinders.

- The hydraulic system is the one that energizes the whole process of lifting making the heavy work seem light.

- The platform is a carrier made for workers or goods.

- The control panels and safety features go hand in hand in providing the function of an easy and safe operation.

When all these come together the lift is at its best effortlessly. However, if even one small part like a pin or sensor fail, the entire system can be affected.

Base and Chassis

The base and chassis are the main parts of the scissor lift. Without a secure and stable base, the whole lift will not be able to perform safely.

Structural Frame

The frame is the chassis which is made of steel that is either reinforced or aluminum, the design of which is to easily accommodate the stresses of heavy lifting hence assure the safety of the operator and others. It is the one that is in direct contact with the ground during taking the weights of the lift and its load.

Wheels and Casters

Or, the lift, depending on the type, may be equipped with solid rubber tires, pneumatic tires, or heavy-duty casters. These are the movable parts that allow the lift to go over different terrains. The rugged tires are for the outdoor lifts which are usually for uneven terrains, while the indoor models run on non-marking tires that are floor-friendly.

Outriggers and Stabilizers

Some scissor lifts are equipped with outriggers or stabilizers, i.e. extendable supports that provide an additional balance. Such are indispensible for rough or uneven terrain and are able to eliminate tipping during operations.

Platform Assembly

As the platform is the place for workers to do their jobs, it has to be strong, spacious, and safe.

Main Work Platform

Usually, the platform is made of heavy duty steel and is able to contain people, tools, and materials. For better safety, it can also have anti-slip flooring.

Guardrails and Safety Gates

Guardrails which are put all around the platform stop falls. Safety gates or chains that are attached to the workers function ensure that they can enter and leave without danger.

Extension Decks

For instance, a scissor lift can have a sliding or fold-out type extension deck, so that a worker may be able to get the required extra reach without repositioning the whole lift.

Scissor Arms (Pantograph Mechanism)

Scissor arms are the most visually striking and at the same time the most famous part of the lifts that take the form of the characteristic “X” shape.

Structure and Function of Crossed Arms

The arms that are made of high-strength steel extend and contract depending on the function that they have, which in this case is to move the platform up and down.

Pins, Bushings, and Joints

Although very small these components which include pins, bushings, and joints are very important as they are the ones that connect the arms, thus they allow a smooth pivoting action. It is also of great importance that the bushings are not worn out and there are no loose pins.

Materials and Durability

Scissor arms are made to be chrome-like by powder coatings or are given a corrosion-resistant finishing so they could be able to resist heavy usage and still be used outside without any problem.

Hydraulic System Components

Without the hydraulic system the power will not be there henceforth the scissor arms would be unable to extend under heavy loads.

Hydraulic Cylinder

The hydraulic cylinder is made of steel, and there is a piston inside it. When a pressurized fluid gets into the cylinder, the piston is extended which consequently moves the scissor arms up. To lower the lift, the pressure must be released as this will retrace the piston.

- The cylinders have to be checked for potential leaks, dents, or even a seal that might be worn out.

- Some of the symptoms of a failing cylinder are abrupt movements and loss of power.

Hydraulic Pump

The job of the pump is to raise the pressure of the fluid and deliver it to the cylinder. One can find that electric motors, diesel engines, or manual foot pumps drive it, depending on the model.

- One of the consequences of a defective pump is the loss of the system’s efficiency and the slow running of the lift.

- The maintenance procedure involves checking for the presence of noises, leaks, or overheating.

Reservoir and Filters

The reservoir is there for the storage of the fluid while the filters are installed to catch any dirt which can be the cause of system damage.

- Hydraulic fluid that contains impurities can cause severe damage to the unit where the pump and the cylinders are located.

- The procedure of checking the fluid that is in the system and replacing the filters is the most important condition to a normal operation of the system.

Hoses and Fittings

Hoses are the parts that connect the various components of the hydraulic system such as the pump, reservoir, and cylinder. They enable the flow of the fluid that is under high pressure hence they must be made from strong materials.

- One of the most common causes of a hydraulic system failure has to be the condition of the hoses such as leaking and being cracked.

- Always make sure to replace the hoses with the ones that the manufacturer recommends.

Power Source

The source of power in a scissor lift determines its capacity, portability, and the environments where it can be used.

Electric Motors and Batteries

The electric version of a scissor lift consists of batteries that are rechargeable, and quiet electric motors, which makes it the first choice for the use of the lift indoors.

- Advantages: Clean operation, low noise, simple maintenance.

- Limitations: The battery does not last long and the power is not enough.

Diesel Engines

To be powered by diesel is a lift that is going to be used outdoors only and mostly in heavy situations.

- Advantages: Great lifting power and a long time of continuous work.

- Limitations: Noisy, emits pollutants, and requires refueling regularly.

Pneumatic Systems

Some lifts are powered by the use of compressed air instead of using regular hydraulic or petrol systems. They are quite common in industries that are very clean such as food and pharma.

- Advantages: Fully clean operation (no leaks of oil).

- Limitations: They cannot work without the air supply and they have lower lifting power.

Control Systems

The control system is the decision-maker of the lift and the operator through it can manage the movements in a safe and efficient way.

Ground Control Panel

The ground control panel from where emergency operations and maintenance checks are done is situated at the base of the lift. Besides the switches for raising, lowering, and emergency stops, it usually has other components as well.

Platform Control Panel

This panel, alongside the work platform, is the main control interface of the operator. Typically, it is equipped with a joystick for steering and lifting.Toggle switches for speed and direction.Emergency stop buttons within easy arm’s reach.

Safety Interlocks

These built-in features protect against dangerously operating the machine. For instance:

- If the guardrail gate is open, the lift will still not move.

- If the load is over capacity, the platform will not go up.

Safety and Stability Features

Safety is the main feature of the scissor lifts and several components have been specifically designed to protect operators.

Tilt Sensors

When the lift is located on an uneven surface these sensors detect it. The system automatically stops further elevation if the tilt angle is unsafe.

Emergency Stop Button

Emergency stops installed both on the platform and at the ground control panels remove all power immediately, thus stopping the machine in the case of a threat.

Overload Protection

The platform equipped with weights sensors will not be lifted when the load is over the manufacturer’s limit. In this way, the potential risks of structural failure and tipping are effectively eliminated.

Guardrails and Harness Points

While guardrails frame the platform, anchor points are there for workers to attach their safety harnesses to. Together, these features vastly eliminate fall hazards.

Drive and Mobility Parts

For mobile scissor lifts, the drive system is just as important as the lifting mechanism.

Tires and Treads

- Solid rubber tires: Perfect for the use of the lift in a closed place.

- Pneumatic tires: Particularly suitable for the machine to be used in uneven ground outside.

- Non-marking tires: Make sure that sensitive floors do not get scratched by the lifts.

Steering System

Some scissor lifts have powered steering that allows the user to operate the machine in a limited space with less effort, whereas smaller models with manual steering are harder to control.

Drive Motors

Such drive motors supply power to the wheels and thus, self-propelled lifts are able to move separately without needing a tow. The first type may be diesel and the other electric, just like in the design of motor cars.

Electrical System

Essentially, an electrical system in a scissor lift is the connection of power, safety, and control. The hydraulic and mechanical segments would not work satisfactorily without the implementation of the electrical system.

Wiring Harness

The wiring harness works like the lift’s nervous system, where the communication between switches, sensors, and control panels and the power source takes place.

- Good insulation is necessary for the prevention of short circuits.

- Checking at regular intervals is very important as it allows the discovering of a worn out part or a loose connection.

Battery Chargers

Electric scissor lifts are powered by rechargeable batteries. The chargers can be either installed inside or be separate, both cases being able to keep the batteries energized.

- Overcharging will make battery lifespans become shorter.

- The most common smart chargers of today come with an automatic shutoff for when the batteries are fully charged.

Fuses and Relays

Fuses are the part that saves the lift from going into an electrical overload, and relays are the elements that allow the current to different sections of the machine.

- One of the common issues with the auto system is the blowing of the fuses and replacement of the fuses is very simple.

- Relays help to ensure that delicate units get the correct power supply.

Braking System

The main function of the braking system is to prevent the scissor lift from rolling away unintentionally or during the time when the operator is using it.

Automatic Brakes

The majority of lifts manufactured nowadays are equipped with an automatic braking system. The system works by the activation of braking whenever the lift stops moving thus it stops there and it cannot be rolled by accident. Therefore, the situation of an involuntary rolling grip on slopes is totally eliminated.

Manual Release Mechanism

If there is no power, the manual brake release installed in the emergency case allows the operator to unload the lift making it safe to move or tow further if needed.

Safety Locking Systems

Some designs of lifting equipment have mechanical locking bars which arrive in engaged mode during maintenance. In this way, the machine is kept in place and accidental releases, which may happen if the technicians are working on it, are prevented.

Accessories and Add-ons

Many scissor lifts can add to the productivity and safety of the operator by having optional accessories.

Lighting Systems

Work lights are the perfect thing to have if you are planning to work during the night or when the visibility is low since it improves the safety of the operator.

Tool Trays and Holders

Tool trays efficiently store the necessary equipment in a well-arranged manner and this assists the user to easily pick up the tools needed while working from a height without the fear of them falling off.

Weatherproof Covers

The covers, on the other hand, protect outdoor scissor lifts from various natural elements such as rain, dust, or strong sunlight which leads to the prolonging of the machine’s lifespan.

Maintenance and Replacement of Parts

Regular servicing of scissor lift parts ensures that the machine is not only safe and reliable but also has a longer life span.

Common Wear-and-Tear Components

The most often replaced parts are:

- Hydraulic hoses.

- The tires and wheels.

- Pins and bushings.

- Electrical switches.

- Batteries.

Preventive Maintenance Schedule

A preventive schedule usually covers:

- Daily checks: Fluids, controls, and tires.

- Weekly checks: Hydraulic hoses, safety sensors, and platform stability.

- Monthly checks: Brakes, structural arms, and electrical systems.

Tips for Buying Replacement Parts

- Only select components approved by the manufacturer for safety.

- Keep a small stock of wear parts that are used frequently.

- Evaluate OEM versus aftermarket parts (OEM guarantees compatibility, aftermarket may be cheaper but less reliable).

Cost and Availability of Scissor Lift Parts

Why, the price of the different types of parts from different manufacturers and sources varies greatly.

OEM vs. Aftermarket Parts

- Parts from OEM (Original Equipment Manufacturer) are always the best fit and meet all safety requirements.

- The price of aftermarket parts is usually lower, but they may not always be made to the same specifications as the original.

Online Suppliers and Dealers

You can buy parts directly from the manufacturers, the authorized dealers, or the trusted online marketplaces that specialize in heavy equipment.

Cost-Saving Tips

- Buy in bulk if you have more than one lift under your management.

- Use refurbished parts if they are available.

- Follow a tight preventive schedule to keep from having major repairs.

Conclusion

Every single part of a scissor lift that includes the base, arms, hydraulics, and safety systems, has a vital function in the smooth, dependable, and safe performance of the machine.

Recognizing these parts is not only a great help in the daily work but also a big safety booster, lower the production of downtime and the cost of maintenance.

In fact, whether you’re an operator, technician, or business owner, the knowledge of the most important scissor lift parts will empower you to take better care of the machine through maintenance, repairs, and making the right investment choices. Over time, it will lead to a more efficient and longer-lasting lift.