Why Indoor Scissor Lifts Are the Most Essential Equipment for the Maintenance of Modern Facilities

With the rise in vertical space utilization, the trend in modern facility management had to find new access modes since traditional methods like ladders hardly fit the modern setups any more. Besides personnel safety, the key goal for Indoor Scissor Lifts is to boost the work speed without compromising on safety measures. A vertically stable lifting platform propped up by these machines can take technicians to lofty heights where they feel as safe as when they are on the ground.

Precision is what makes it possible to do a small-scale warehouse or a retail store floor very efficiently. Dissimilarly to the outdoor ones, Indoor Scissor Lifts are the result of the special engineering that takes into account the physical constraints of the interior spaces using emphasis on very small footprints, zero emissions, and floor protection. Whether it is an HVAC maintenance or a lighting upgrade project, these lifts will keep the indoor operations efficient and run without hitches.

Top 5 Reasons To Choose Indoor Scissor Lifts:

1. Maximum Safety and Fall Prevention

The foremost consideration in utilizing an Indoor Scissor Lift is the substantial decrease in workplace accidents. Ladders are naturally unstable and also, one gets restricted in movement and cannot extend their range of motion that far. Instead, scissor lift offers a workspace that is fully enclosed and complies with stringent OSHA safety requirements thus even your most complicated ‘work at height’ will be less risky.

- Continuous Guardrail Protection: Every iteration of Indoor Scissor Lifts comes equipped with perimeter railings to thwart accidental falls and let the technicians use the full extent of their hands while servicing complex systems.

- Automatic Leveling Sensors: To preserve their stability on warehousing floors, these lifts are fitted with sensors which will inhibit any further elevation if an unsafe incline is detected by the machine.

- Safety Interlocks: Some safety features that are standard in today’s Indoor Scissor Lifts are “dead-man” switches along with emergency stop buttons which let the operator have the final say over the machine’s movements at any time.

2. Optimized for Confined Indoor Spaces

A major problem in facility management is often how to get equipment through narrow aisles and standard-size doors. The manufacturers of Indoor Scissor Lifts have perfected the “slim-line” concept and churned out machines that not only pack the required punch but are compact enough to penetrate proposals with the most restricted floor plans.

- Narrow Chassis Design: Many Indoor Scissor Lifts keep their width in the 30- to 32-inch range, which allows them to conveniently pass through standard single door openings without having to be taken apart.

- Zero Turning Radius: A good number of the electric versions are prepared with sophisticated steering mechanisms whereby a machine can make a full turn within its own length. This becomes an incredible asset when handling high-density storage racks.

- Retractable Components: Indoor Scissor Lifts can be transported in an elevator with low headroom or moved under a low-hanging ventilation duct by utilizing features such as fold-down handrails.

3. Clean and Quiet Electric Operation

Hospitals and schools as well as office buildings are among the few indoor environments where a very high degree of environmental control is needed. Since Indoor Scissor Lifts utilize batteries almost exclusively to power the equipment, they do not emit any CO or other pollutants garanteeing a healthy air quality at the place that is being maintained.

- Zero Exhaust Emissions: Deep-cycle batteries power Indoor Scissor Lifts, therefore they do not generate carbon monoxide or other toxic fumes, hence their utilization in totally closed areas without the necessity for ventilation is completely safe.

- Silent Motor Technology: The very quiet turning of these lifts means maintenance can take place in the middle of the working day without bothering anyone.

- Non-Marking Tires: It is sort of a trademark of the Indoor Scissor Lifts to equip themselves with the specialty solid rubber tires that do not leave black streaks or scuff marks on high-end tile, epoxy, or polished concrete floors.

4. Enhanced Labor Productivity

Time is, of course, money. At the same time, labor is the most costly input in maintenance. Indoor Scissor Lifts can help here by saving the facilities more than half of the time originally allotted for a task. Instead of going up and down the ladder back and forth multiple times, the technician can bring every part, tool or piece of equipment that is heavy up all together in one single lift.

- Extended Work Platforms: Indoor Scissor Lifts are generally equipped with “roll-out” platform extensions that significantly enlarge the available horizontal reach so that technicians can get to a point that is initially obscured by machinery.

- High Lift Capacities: At least two technicians can share the same working platform when the indoor scissor lift being used has a load capacity of 500 lbs and beyond.

- On-Platform Power: In many cases, platforms have AC power outlets installed for operators who get to enjoy no hassle when using powered hand tools without being troubled by the extension cords.

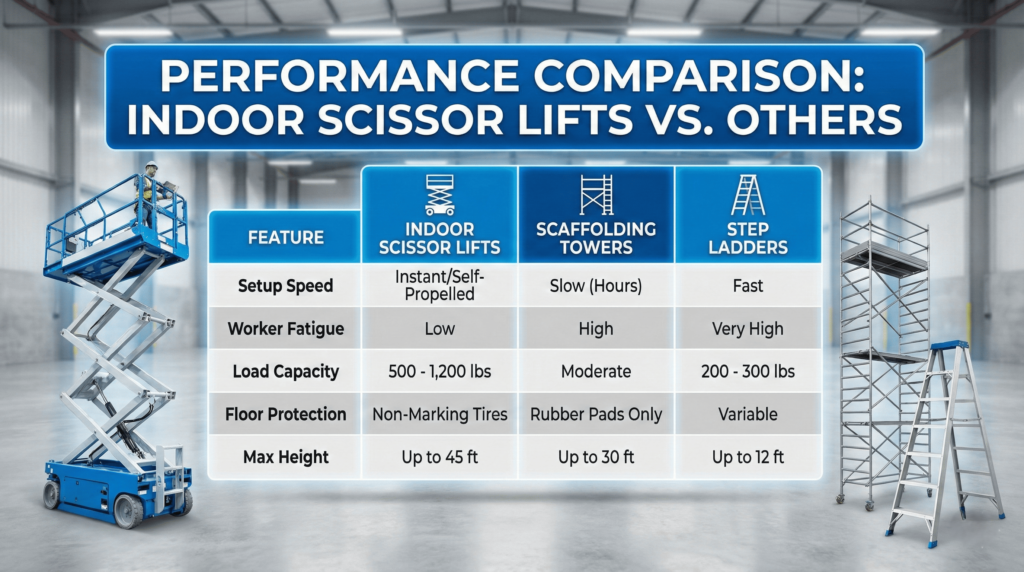

Table: Performance Comparison: Indoor Scissor Lifts vs. Others

| Feature | Indoor Scissor Lifts | Scaffolding Towers | Step Ladders |

| Setup Speed | Instant/Self-Propelled | Slow (Hours) | Fast |

| Worker Fatigue | Low | High | Very High |

| Load Capacity | 500 – 1,200 lbs | Moderate | 200 – 300 lbs |

| Floor Protection | Non-Marking Tires | Rubber Pads Only | Variable |

| Max Height | Up to 45 ft | Up to 30 ft | Up to 12 ft |

5. Long-Term Cost Savings for Facilities

It is true that buying Indoor Scissor Lifts is making a capital investment but the advantages of such a move are very obvious in the long run. By nesting people and time-saving measures thus ensuring quicker repairs and by also avoiding costly workplace accidents, these machines become financially self-supporting in just a couple of years.

- Lower Insurance Premiums: Liability insurance can be less costly for a company that uses certified Indoor Scissor Lifts in place of ladders as it conveys a message that the company is serious about safety efforts.

- Minimal Maintenance: An electric drivetrain is far less complex than one with an engine due to limited moving parts resulting in lower servicing costs and potentially machine longevity.

- Multipurpose Tool: Indoor Scissor Lifts help refold the specialized equipment that once had to be used for seasonal signage changes or stocktaking into a very few, single pieces of equipment.

FAQs: Indoor Scissor Lifts

How tall, on average, are Indoor Scissor Lifts?

Typically, a standard Indoor Scissor Lifts will have a platform height anywhere within 19 to 32 feet thus giving a total working height of roughly 25 to 38 feet including the operator’s reach.

Are Indoor Scissor Lifts compatible with carpet floors?

Definitely if the carpet is short pile and the underlying floor is structurally sound. The non-marking tires with which Indoor Scissor Lifts are fitted are suitable for use on any indoor surface.

How frequently do Indoor Scissor Lifts need to be recharged?

One full day shift of 8 hours or so is what a typical electric scissor lift can last with one single charge depending on how heavily it is used. It is advisable to charge them overnight so as to have a fully charged battery in the morning.

Can a person alone operate Indoor Scissor Lifts?

Yes, indeed. In fact, basically, Indoor Scissor Lifts are manufactured in such a way that even a one-person operation with safety can be achieved.

Is special floor loading necessary for Indoor Scissor Lifts?

Even though these machines are heavy, this weight is spread over four tires. Modern commercial concrete “slab” floors are usually more than capable of taking the load of these vehicles.

Are Indoor Scissor Lifts also fit for outdoor use?

They can be used physically outside, however, Indoor Scissor Lifts have been tested and rated for “zero wind” conditions. So, leaving your lift outdoors in windy weather becomes a risky proposition since such units do not have wind-stability ratings like the rough-terrain models.

Is there a need for training when operating Indoor Scissor Lifts?

Undoubtedly. OSHA mandates special training for Indoor Scissor Lifts operators which must be followed by a competency confirmation through a practical evaluation to make sure that the operators are well versed in the safety requirements and that they know how to adequately handle the machine controls.