The Ultimate Guide to Gas Powered Scissor Lifts

Equipping the right machinery often determines the success of a heavy construction or industrial maintenance task in today{apos}s fast-pacing world. Among various aerial work platforms, gas powered scissor lift are strong and reliable machines that mainly cater to outdoor applications.

Unlike electric lifts, which are limited by battery life and charging times, gas powered lifts deliver the raw power and stamina necessary for hard, all-day work. No matter if you are a project manager with years of experience or a contractor eager to enlarge your fleet, it is crucial to grasp the potential of these machines.

This in-depth guide goes beyond the surface to the workings, advantages, and safety guidelines of gas powered scissor lifts, thus taking your projects to the next level.

What is a Gas Powered Scissor Lift?

A gas powered scissor lift refers to a type of working at height equipment (WHA) primarily used to vertically raise people and their tools from ground level to height. Gasoline or diesel-fueled engines are employed to generate heat to power the hydraulic pump and raise the crisscrossing “scissors” supports found on such machines.

Because these lifts are made practical and dependable in every detail, they can handle being exposed to industrial outdoor scenarios where one might expect limited or no electric power availability.

- Powerful Motor Mechanism: A gas powered scissor lift’s core is its internal combustion engine. Thanks to this motor, high torque is available which allows the machine to lift heavier loads than many electric models. Also, the power output guarantees that the hydraulic system runs efficiently even during near maximum capacity lifts.

- Abilities to Cope with Rough Terrain: Quite a few gas powered models come set up with features that will make these machines capable even when the ground is at its most unlevel. Usually, this means four-wheel drive and tires of the heavy-duty type with deep treads, providing the necessary traction to go through mud, gravel, and loose soil without getting stuck.

- Significantly Higher Weight Capacities: These lifts generally represent the heavyweight category of the industry. They come with the capability of carrying multiple workers alongside their heavy tools and materials. This way, the time consuming back and forth trips are minimized, thereby substantially increasing productivity on the site.

Why Choose a Gas Powered Scissor Lift Over Electric?

Sometimes, the deciding factor comes down to whether the working environment is inside or outside and to what extent the work is. If electric lifts serve beautifully indoors, where silence and zero-emission are the priorities, a gas powered scissor lift will take over where the electric ones cannot survive. These are the naïve beasts that power the big construction sites and the maintenance of outdoor premises.

- Unlimited Runtime: Among the greatest benefits is the absence of charging breaks. This way, a gas powered scissor lift can just keep going without having to stop every couple of hours. This is the moment when time-conscious projects can become a reality since there is no necessity of several hours of battery charging downtime anymore.

- Better Gradeability Up the Hills: Gas engines generally give better gradeability thus enabling the machine to ascend steeper slopes and ramps with greater ease than it would be with an electric one. In case there is a significant difference in height at your job site or you have ramps, the extra power of a gas engine, in this case, is indispensable.

- Ability to Withstand Extreme Weather: Such machines, indeed, are tough to beat in terms of their ability to weather the elements. In the winter time, for example, battery systems may suffer from diminished performance while a well-maintained gas engine is often more dependable, from scorching heat to freezing cold.

Top Applications for Gas Powered Scissor Lifts

Thanks to the adaptability of a gas powered scissor lift, it has become an essential piece of equipment in numerous industries. The fact that it can extend to great heights while still providing a secure platform means that workers can carry out their tasks safely in places that ladders or scaffolds hardly reach.

- Construction Sites: The very typical address for the usage of such a lift. The lifts help to carry out various tasks such as framing, siding installation, roofing, and bricklaying. They prove to be effective for the early stages of construction when the ground is still very messy as they can easily move over the debris-covered ground.

- Facility Exterior Maintenance: Different large industrial complexes, stadiums, and shopping centers use these lifts for exterior repairs. Lighting at high levels, window cleaning and signage maintenance are examples of work that have been made safer and faster through the use of a scissor lift.

- Event Setup and Production: In the ca\e of an outdoor concert or festival, a gas powered scissor lift goes a long way in facilitating quick highpoint access while also providing the required platform for the safe handling and positioning of heavy audio-visual equipment such as stage lighting, speakers, and microphones.

Gas vs. Electric Scissor Lifts: A Comparison

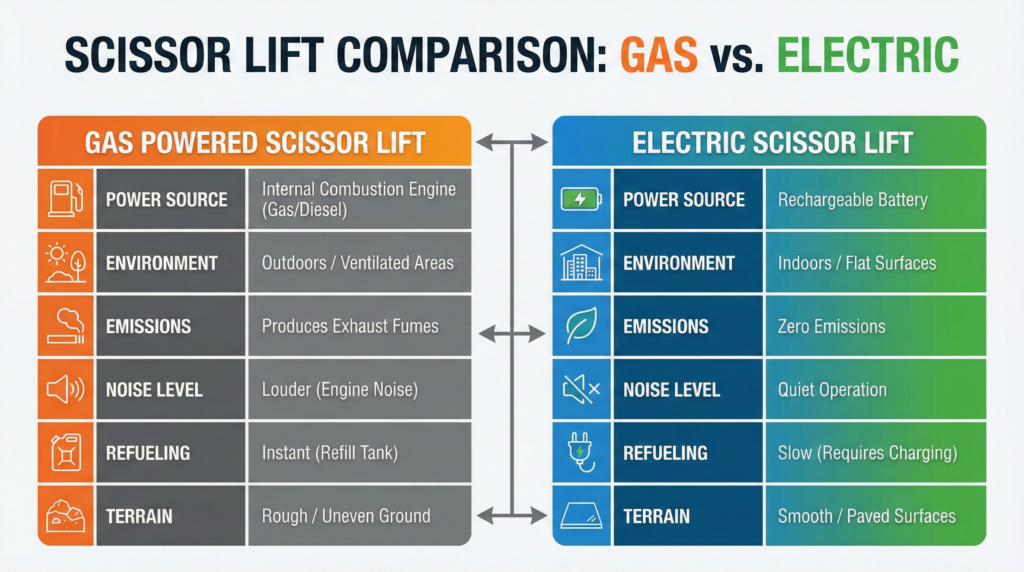

Another way to understand when a gas powered scissor lift comes in handy is to picture it in a direct comparison with electric models. The table below marks the focal differences that usually hook in or repel buyers or renters.

| Feature | Gas Powered Scissor Lift | Electric Scissor Lift |

| Power Source | Internal Combustion Engine (Gas/Diesel) | Rechargeable Battery |

| Environment | Outdoors / Ventilated Areas | Indoors / Flat Surfaces |

| Emissions | Produces Exhaust Fumes | Zero Emissions |

| Noise Level | Lier (Engine Noise) | Quiet Operation |

| Refueling | Instant (Refill Tank) | Slow (Requires Charging) |

| Terrain | Rough / Uneven Ground | Smooth / Paved Surfaces |

Essential Safety Protocols for Operation

Use of a gas powered scissor lift by itself poses inherent risks, which must be mitigated by stringent implementation of safety measures. The kinky nature that these lifts are versatile enough to handle uneven terrain also means that it is the environment hence safety mostly outdoor play a major role in safety more than just a lift used indoors or inside construction facility.

- Proper Ventilation: Operating a gas powered scissor lift inside any totally closed environment is forbidden without proper ventilation. This mainly concerns carbon monoxide present in exhaust fumes that is fatal if breathed. However, if the operation has to be carried out in a partially enclosed space such as a parking garage, then proper fresh air circulation should not be compromised at any cost.

- Ground Assessment: It is the duty of the lift operator to carry out a ground inspection before elevating the platform to identify potential hazards. Such inspection will also help confirm if the lift is standing on a solid base. Soft ground, holes, and debris are just some of the things that might cause the lift to become unstable.

- Monitoring Weather Conditions: Because these machines are mainly used in outdoor settings, wind speed comes at the top of factors that affect safety. Most manufacturers have wind speed limits beyond which the platform should not be left up. Therefore, lowering the platform becomes a must whenever the wind continues to gust above the safety-limit speed so as to eliminate the risk of overturning.

Maintenance Tips for Longevity

If you want your gas powered scissor lift to work well and stay safe, i.e., not riddled with issues, then you must maintain it regularly. Besides requiring less maintenance overall due to no engine/ motor and no fuel or oil change, electric lifts on a battery level demand more attention to their electrical/hybrid battery systems whereas gas lifts are more vehicle-like in their upkeep of engines and hydraulics.

- Routine Engine Maintenance: Besides oil checks, coolant levels, and air filter changes daily, engine performance degradation may also result from a dusty construction environment due to a clogged filter. It is necessary to change engine oil regularly to prolong its lifetime.

- Proper Function of the Hydraulics: The hydraulic fluid refers to the vehicle lift system’s life force. Check hoses and fittings for signs of deterioration such as cracks, leaks, or damage. Likewise, even if the leak is minor, it can still cause pressure to drop, leading to the platform slowly drifting or being unable to lift heavier weights safely.

- Check Tires Regularly: The tires of a gas powered scissor lift are typically foam-filled or solid rubber to prevent punctures. Nevertheless, they still need to be examined for big tears, chunks of rubber missing from the surface, and separation from the rim which can all potentially lead to issues regarding the machine’s stability when running on rough terrain.

Things to Ponder Over When Choosing to Rent a Gas Powered Scissor Lift

Putting your money into a gas powered scissor lift is no small matter. Be it a new purchase or just a rent for a particular job, having a few considerations in mind will make sure that you get the most of your investment in terms of value and performance.

- Height of Platform Requirement(s): The maximum height you need to reach should be accurately measured. Besides, you should know that working height normally exceeds the platform height by 6 feet. It is best to choose a model that can reach your desired height without having to stretch its limit to the maximum.

- Load Capacity Needs: You should add up the weight of the workers, tools, and materials that will be on the platform when it is fully loaded. Make sure the lift that you go for has a safe working load (SWL) which is more than your calculation so that you do not trigger overload protection mechanisms.

- Job Site Accessibility: The ease of getting the lift to the location of the work should also be taken into account. Is the size of the machine such that it can easily go through the site gates? It should be noted that heavy gas lifts are wider than their electric counterparts. You hence have to make sure that the machine’s dimensions allow it to pass through access points in your particular job site.

FAQs: Gas Powered Scissor Lifts

Can I use a gas powered scissor lift inside a building?

Technically speaking, it is a no under any normal circumstances. This is because gas powered scissor lifts emit exhaust gases containing carbon monoxide which is harmful in enclosed spaces, plus, they are louder than the electric models. However, there may be a case when the indoor area is a very large, well-ventilated warehouse with open bay doors, then it might be allowed but an electric or dual-fuel model is almost always the safer and preferred choice for indoor work.

How high can a gas powered scissor lift go?

It depends on the model. However, in general, the height gas powered scissor lifts can reach is greater than what regular electric ones can offer. The typical working height range is approximately 26 to 50+ feet. Some special rough terrain models even extend their heights way beyond the 60-foot mark and although rarely, they have been used for accessing multi-storey exteriors too.

What differentiates a rough terrain scissor lift from a standard gas lift?

While a large number of gas powered scissor lifts are indeed designed and marketed as rough terrain (RT) models, not all of them are. An authentic “Rough Terrain” lift is characterized by features like 4-wheel drive, an oscillating axle for maintaining wheel contact with the ground, and tires with aggressive tread. A standard gas lift will most probably just come with an engine but no such fancy suspension as required for very difficult ground conditions.

Does operating a gas powered scissor lift require a license?

Yes, the employer is required by OSHA (USA) and other international safety agencies to ensure that operators are adequately trained and certified. However, only a “driver’s license” in the traditional sense is not what is needed but completion of an aerial lift certification program which specifically addresses safety, operation, and hazard recognition requirements related to the lift type being used is mandatory.

What is the maximum load that a gas powered scissor lift can carry?

Such lifts have been traditionally associated with great capacities. As per different sizes and models, the typical range is from 800 lbs. to more than 2,500 lbs. The capacity being so high, not only multiple workers can be lifted but also heavy equipment like welders or compressors.

Which is better for a scissor lift, diesel or gasoline engine?

Diesel engine-powered scissor lifts are often larger rough terrain models mainly due to the higher torque and better fuel economy these engines deliver. On the other hand, gas engines (or dual fuel gas/propane) are still widely used in certain segments. While outdoor construction sites with other diesel machinery on-site are natural places for diesel, gas/propane may be a fuel choice if a cleaner burning fuel is desired.

How do I get my gas powered scissor lift to the job site?

Due to their bulk and weight, gas powered scissor lifts are not tow vehicles, even not by a normal pickup truck. These may require a semi-trailer or flatbed trailer for their transport. Most rentals from a local dealer come as a package of delivery service that is by far the most comfortable and safest option for the majority of users.

A Wise Decision for Gas Powered Scissor Lift

The gas powered scissor lift is still one of the most indispensable pieces of equipment in the construction and maintenance sectors. The combination of its ability to handle heavy loads and its mobility-enhancing features such as 4WD gives it a knack for even the most challenging outdoor type of projects.

On the other hand, when it comes to electric, the industry is witnessing a surge in the number of electric alternatives, but overall, in terms of raw power and an unlimited run time, the gas engine offers a reliability level which is quite hard to find in remote or tough heavy-duty environments.

Also, you will profit the most from your machines if your knowledge of their specific benefits, maintenance demands, and safety requirements, as detailed in this guide, is thorough. Be it the heavy steel beams you are lifting or the delicate restoration work being done on a building’s façade, the correct gas powered scissor lift will provide you with the sturdy base you need to succeed.