How to Do a Pre-Use Scissor Lift Pre-Use Inspections

A scissor lift refers to a necessary aerial work platform, which is powerfully and most probably safe and efficient, used in construction, maintenance, and event production for the purpose of elevation. Anyway, to assure the safety of the operators and everybody else within the working area, it is a must, first and foremost, to perform a detailed scissor lift pre-use inspections before any usage of the scissor lift happens.

These scissor lift pre-use inspections enables the detection of potential dangers, malfunctions of the equipment, and even wearing which, can compromise safety as well as lower the output of the work. This step-by-step manual will show you the most important steps for a pre-operation check of your scissor lift to help you keep up with the law, prevent accidents, and get the best out of your device.

Why Scissor Lift Pre-Use Inspections Are Vital for Scissor Lift Safety?

Checking your scissor lift before use is not just a safety ritual but a very important habit that can lead to the avoidance of serious accidents at the workplace as well as the prevention of expensive equipment breakdowns. Environment where one can operate his/her scissor lift is full of hazards, there are risks such as tip-overs, falling from heights, the machine breaking down, and even short circuits. A thorough examination:

- Locates the damages that can be seen like cracked welds, loose bolts, or leaking of the hydrauliс.

- Makes sure that all safety features and emergency control are able to work.

- Determines if the lift is safe to be used in the planned work environment with the specified load.

Not performing these inspections might end with fatal injuries and costly downtime. OSHA along with other industry safety standards require that inspections be done on a daily basis in order to lessen these risks. Therefore, making this check part of your standard operations shows safety culture and care for the people who work.

Scissor Lift Inspections Preparation: What to Know Before Starting?

Prior to your scissor lift inspections routine, you need to collect the following checklist:

- Operator’s Manual: Check the manufacturer’s manual to get the model-specific safety and inspection checklists as well as the warnings. Each lift differs from the other.

- Personal Protective Equipment (PPE): Get yourself in a safe gear such as a hard hat, gloves, and safety shoes.

- Inspection Checklist: Prepare a printed or rather digital checklist, which is your type of lift, thus, you will not miss any point of an inspection.

- Worksite assessment: Knowing the condition of the workplace will help you set proper focus during the inspection, thus, you can check not only ground but also overhead space.

With all the necessary items ready, the inspection may be conducted in a systematic and efficient manner. With all the necessary items ready, the inspection may be conducted in a systematic and efficient manner.

Key Components for Scissor Lift Inspections Routine

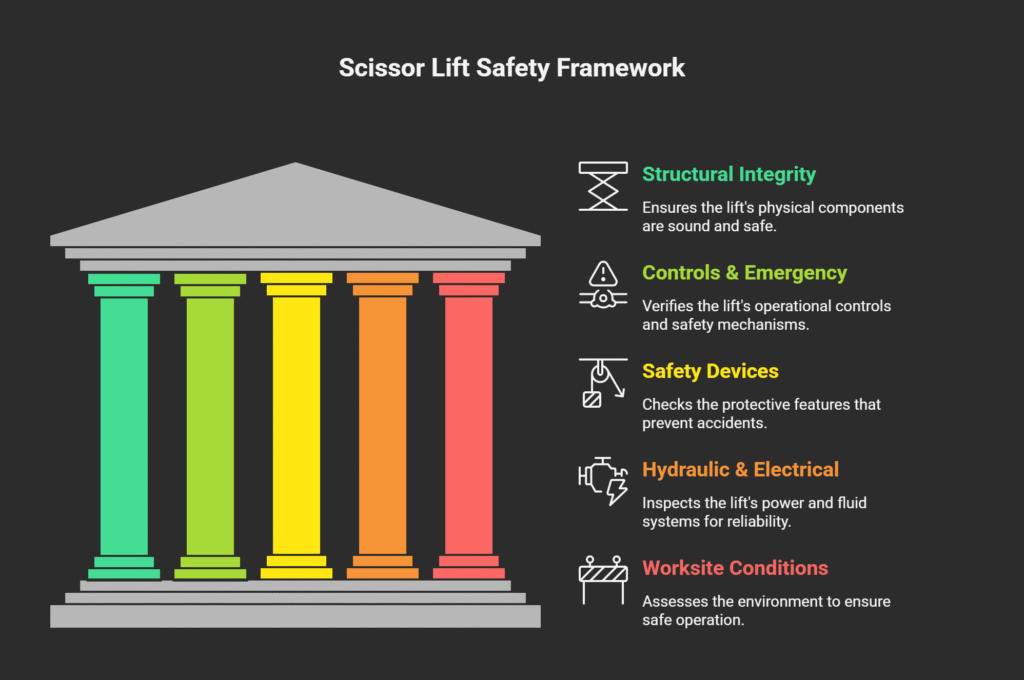

The Scissor Lift Pre-Use Inspections should include structural, operational, and safety aspects of the scissor lift. These are the main points that have to be deeply examined:

-

Visual Structural Inspection

- Look at the platform and the guardrails for damages, missing parts, or unsafety gates.

- Check the scissor arms and the welds for the cracks, rust, or dents.

- Make sure that the tires/wheels are without wear, correctly inflated, and undamaged.

- Search for leaks in the hydraulic lines, oil seals, and fuel tanks.

- Confirm the presence and the readability of the safety decals and the operational instructions.

-

Operational Control Checks

- Run through all the operational controls (raise/lower, drive, steering) and see if they are working without any problems, and are responsive, and if the action is smooth.

- Check if the emergency stop button and the system for emergency lowering are working properly.

- Make certain that the upper and lower control panels can override each other as planned.

- Ensure that all the indicators, alarms, and lights (backup alarms, motion alarms) are in working condition.

- Make sure that buttons and switches are clean, easy to see, and not blocked by anything like paint overspray.

-

Safety Devices and Systems

- Make sure that guardrails, toe boards, and gate latches are not damaged and are securely fastened.

- Brakes and wheel locks should be checked for strong and good engagement.

- Ensure that the tilt sensor and other stability warning systems are working properly.

- If any, check for the presence and condition of fall arrest personal anchorage points.

- Perform a local job risk check for the above-mentioned factors such as floor conditions, overhead hazards, slope degree, and clean pathways free of obstructions.

Table: Scissor Lift Pre-Use Inspections

| Inspection Area | What to Check | Why It Matters |

| Structural Integrity | Platform, scissor arms, tires, decals | Prevent falls, tip-overs, equipment damage |

| Controls & Emergency | Operation of lift controls, emergency stops, alarms | Ensures responsive and safe operation |

| Safety Devices | Guardrails, brakes, tilt sensors | Protects from falls and unstable operation |

| Hydraulic & Electrical | Leaks, battery level, wiring, hoses | Prevents breakdowns and electrical hazards |

| Worksite Conditions | Terrain, overhead clearance, weather | Ensures safe environment for operation |

Step-by-Step Guide for Scissor Lift Pre-Use Inspections

This is a stepwise detailed manner by which you can carry out your scissor lift pre-use inspections checklist before use.

Step 1: Walk Around the Equipment: Get a hold of the complete visual examination of the lift. Check for any kind of damages, leaking of the fluid, missing or loose parts, and wear and tear. Make sure that all the safety decals are readable and present.

Step 2: Platform and Guardrail Inspection: Inspect the security of the guardrails and gates as well as the cleanness of the platform floor. Make sure that toe boards are without damages and all safety chains or doors can be closed properly.

Step 3: Functional Control Test: Turn the power on the scissor lift. Both the upper and the lower control tested for performing smoothly in all the functions of lifting, lowering, driving, stopping, steering, and emergency stop. Make sure that the overrides between the controls are done properly and the emergency lowering is moving smoothly.

Step 4: Check Safety Devices: Check on brakes, wheel locks, and condition and locking of outriggers if equipped by engaging the wheel brake and

Step 5: Inspect Hydraulic and Electrical Systems: Look under the lift for any hydraulic leaks, check the battery charging and fluid levels, examine the cables and hoses for any cracks or frays and also check if the emergency power cut-off is working.

Step 6: Evaluate Worksite Conditions: Check if the ground is firm and level without any holes, obstructions, or slopes that exceed the manufacturer’s limits. Also, look for power lines or other objects that may be in your path.

Essential Pre-Use Inspections Tips for Operators

Make your scissor lift pre-use inspections most effective by following these tips:

- Make it a point to always record the inspection results indicating any defects or the corrective actions that have been implemented.

- Inspections and lift operations should only be carried out by personnel who are trained and authorized.

- Defects should never be overlooked; thus, if a scissor lift is found to be defective in any inspection point, it should be immediately tagged as out of service.

- Inspect the equipment at the start of every shift and also when there is a change in the operator.

- Use the manufacturer’s detailed inspection instructions for your unit to guide the check.

Frequently Asked Questions (FAQs) About Scissor Lift Pre-Use Inspections

How often should a scissor lift pre-use inspection be conducted on a scissor lift?

Pre-use inspection needs to be implemented before each shift or use in order to ensure the safety of the users and proper functioning of the equipment.

What should I do if I find a defect during the inspection?

Please put a tag on the defect equipment indicating that it is out of service and notify the management about it at once. Do not operate the lift until the repair is done.

Can I operate a scissor lift without a pre-use inspection?

Absolutely not. An operation without an inspection exposes one to the risk of a serious injury and is a violation of OSHA safety standards.

Are there differences in inspection for electric vs. rough terrain scissor lifts?

Certainly, electric lifts are burdened with extra battery and electrical system checks, while rough terrain lifts require detailed tire and stability checking.

What personal protective equipment (PPE) is needed during inspection?

The operator should be outfitted with a hard hat, gloves, safety boots, and if necessary, a fastening harness for fall protection.

How do I test the emergency lowering system?

You should follow the manufacturer’s instructions and confirm that the platform is coming down smoothly right after activating the emergency lowering method.

Are pre-use inspections required by law?

Definitely Yes. According to OSHA, lifting equipment such as scissor lifts need to go through daily and periodic inspections to warrant safe operations.

Scissor Lift Pre-Use Inspections: Wrap-Time

Performing an in-depth pre-use inspection is the first and most important thing to do if you want to secure efficient and safe functioning of a scissor lift. By implementing this detailed plan, you can uphold a high standard of safety and lengthen the life of your device while giving yourself and the others safety.

If you’d like to get more detailed checklists, model-specific inspection forms, or expert advice on how to keep your scissor lift in top condition, please come to scissorlifts.org, a place full of resources and professional insights.