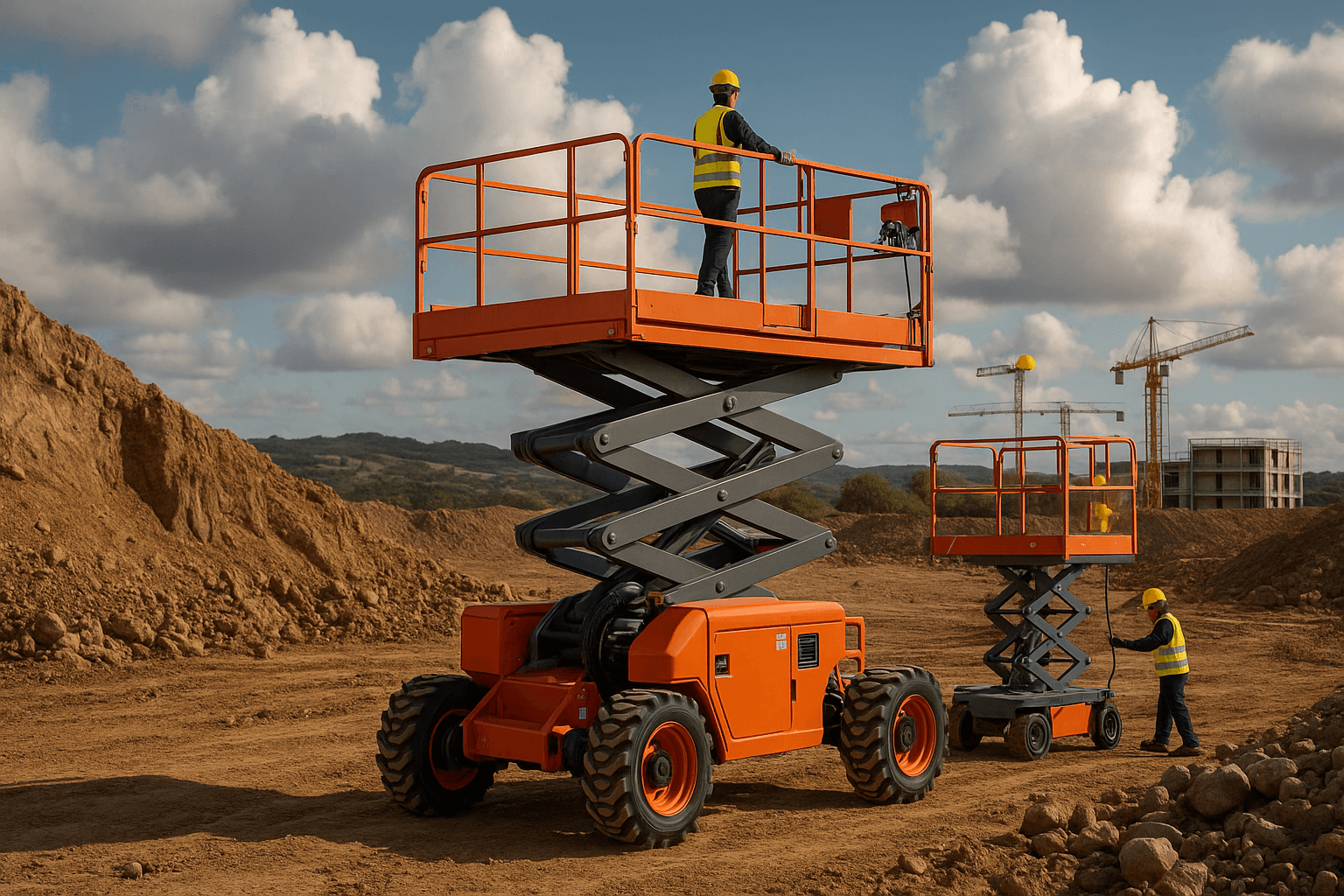

A rough terrain scissor lift is a robust and versatile elevated work platform designed specifically for outdoor construction, maintenance, and industrial applications where uneven, loose, or challenging ground conditions are present. These lifts are equipped with heavy-duty tires, enhanced traction systems, and advanced hydraulic features to ensure stability, safety, and efficiency on rugged terrains.

Key Features of Rough Terrain Scissor Lifts

- Enhanced Stability and Safety: Equipped with large-sized tires, anti-tilt systems, and automatic leveling outriggers that adapt to uneven surfaces, ensuring a secure working platform.

- Superior Traction and Mobility: They feature four-wheel drive and deep-tread tires or tracks for better grip on gravel, dirt, mud, or rocky grounds, enabling smooth traversal over obstacles.

- High Ground Clearance: Designed with high ground clearance, allowing them to pass over obstacles and navigate slopes up to 45%, making them ideal for outdoor rugged landscapes.

- Load Capacity and Reach: These lifts typically support substantial weight (up to 750 kg or 1650 lbs) and offer impressive vertical or horizontal outreach for maximum accessibility.

Benefits of Using a Rough Terrain Scissor Lift

- Versatility: Suitable for a wide range of outdoor tasks across construction sites, infrastructure projects, and maintenance of irregular surfaces.

- Improved Productivity: Ability to transport personnel and materials quickly over challenging terrain increases efficiency and job site throughput.

- Safety Features: Includes outriggers with auto-leveling, tilt sensors, emergency stop, and fall protection, which make work safer on uneven or unstable grounds.

- Eco-Friendly Options: Some models now feature electric or hybrid drives, combining high performance with lower emissions and quieter operation, suitable for sensitive environments.

Popular Models & Innovations

Leading manufacturers such as Haulotte, MACO, and others have developed advanced rough terrain scissor lifts, focusing on maximum stability, durability, and ease of maintenance. For example, Haulotte’s PULSEO range offers models capable of climbing slopes up to 45%, with real-time diagnostics and telematics for optimal fleet management.

Applications

- Construction on muddy or rocky sites

- Infrastructure maintenance in remote areas

- Utility installation and repair

- High-rise building exterior work

- Emergency response in difficult terrains

In conclusion, a rough terrain scissor lift is essential for outdoor projects where standard scissor lifts cannot operate safely or efficiently. Its rugged design, safety features, and mobility enhancements make it an invaluable asset for demanding environments.

What is a Rough Terrain Scissor Lift?

A rough terrain scissor lift is a heavy-duty aerial work platform designed specifically for outdoor use on uneven, sloped, or rugged surfaces such as construction sites, rocky grounds, and muddy or gravel roads. Unlike regular scissor lifts, these machines are built with features that enable them to safely and efficiently navigate challenging terrain conditions while providing a stable and secure elevated workspace.

Key features of rough terrain scissor lifts include large, reinforced tires with strong traction, four-wheel drive (4WD) for improved mobility, and high ground clearance to pass over obstacles. They also come equipped with hydraulic outriggers that provide additional stability by automatically leveling the machine on uneven ground. The platform is typically spacious, capable of supporting multiple workers and heavy materials, with some models offering extension decks for increased working area.

These lifts often use diesel or dual-fuel engines for enhanced power and longer operating times suitable for remote or outdoor locations. They are capable of safely climbing slopes with gradeability up to about 40-45%, making them highly versatile for various rugged applications. Safety is a key focus, with features such as tilt sensors, fall protection, and emergency stop systems integrated into the design.

In summary, a rough terrain scissor lift is a specialized machine engineered to provide reliable, stable, and safe access to height in outdoor environments where traditional lifts cannot operate effectively due to uneven or rough ground conditions

Compare rough terrain scissor lift vs telescopic boom lift

Here’s a comparison between rough terrain scissor lifts and telescopic boom lifts:

| Feature | Rough Terrain Scissor Lift | Telescopic Boom Lift |

|---|---|---|

| Movement | Vertical movement only (up and down) | Vertical and horizontal reach (extends straight out) |

| Reach Height | Moderate working heights, typically up to about 30-40 feet | Much higher working heights, often 40-185 feet |

| Platform Size and Capacity | Larger platform, supports more workers and tools (up to 1000+ kg) | Smaller platform with lower load capacity (typically 200-400 kg) |

| Maneuverability | Limited to vertical raising/lowering; less flexible around obstacles | Highly maneuverable; extends over or around obstacles |

| Terrain Capability | Designed for rough terrain with 4WD, high ground clearance | Some models have rough terrain capabilities; better on uneven ground but less stable on slopes |

| Best Use Cases | Jobs needing stable, spacious platforms; ideal for heavy loads vertically | Jobs needing high elevation and horizontal outreach to access difficult spots |

| Safety and Stability | Very stable due to wide base and outriggers | Stability depends on outrigger deployment and lock mechanisms |

| Indoor vs Outdoor Use | Primarily outdoor due to size and rough terrain features | Versatile for indoor and outdoor with varying boom sizes |

| Operating Costs | Generally lower due to simpler hydraulic design | Higher due to complex extendable boom arms and maintenance |

Stability and ground prep requirements for each machine

Rough terrain scissor lifts and telescopic boom lifts both require specific stability and ground preparation considerations to ensure safe operation, especially in challenging outdoor environments.

Rough Terrain Scissor Lift Stability and Ground Prep

-

Stability Features: These lifts have a wide base, large tires, and hydraulic outriggers or leveling jacks to provide a stable platform on uneven terrain. Automatic leveling systems adjust the lift to maintain horizontal balance. Anti-tilt sensors and heavy counterweights further enhance stability.

-

Ground Prep Requirements: Operators should ensure the ground is firm and compacted enough to support the machine’s weight without sinking or shifting. Loose soil, mud, or gravel may require additional ground stabilization measures such as mats or compacting rollers. Ground slopes should be within manufacturer guidelines, typically less than 5 degrees laterally when elevated, and proper setup of outriggers is essential to level the platform.

Telescopic Boom Lift Stability and Ground Prep

- Stability Features: These lifts rely heavily on outriggers deployed around the base to stabilize the machine during operation. The outriggers distribute the lift’s weight and counterbalance the boom’s extended position. Many have sensors that detect unsafe tilt conditions and prevent operation when stability is compromised.

- Ground Prep Requirements: The ground must be solid and level enough to support the outriggers and the concentrated load without subsidence. Uneven surfaces typically require the use of crane mats or leveling pads under outriggers. Ground preparation is often more critical than scissor lifts due to boom lift’s higher center of gravity when extended. Operators must confirm the slope limits as specified by the manufacturer, often stricter for telescopic booms around 3-5 degrees.

Summary

- Rough terrain scissor lifts offer inherent stability with their wide base and built-in leveling systems, suited for somewhat uneven but firm ground.

- Telescopic boom lifts require more meticulous ground prep and outrigger stabilization due to higher elevation and outreach creating a greater tipping risk.

- Both machines demand adherence to manufacturer guidelines on ground slopes and proper setup to maintain operator safety and equipment integrity.

These ground prep and stability practices help ensure operational safety and optimal performance on rough or uneven terrains.