Aerial lifts are vehicle-mounted equipment used to raise workers using extensible platforms. For high work sites like roofs and HVAC equipment, these lifts are fantastic; they also provide a perfect substitute for hard-to-reach tasks when scaffolding is not the best choice. Still, running this equipment calls for constant safety first thought.

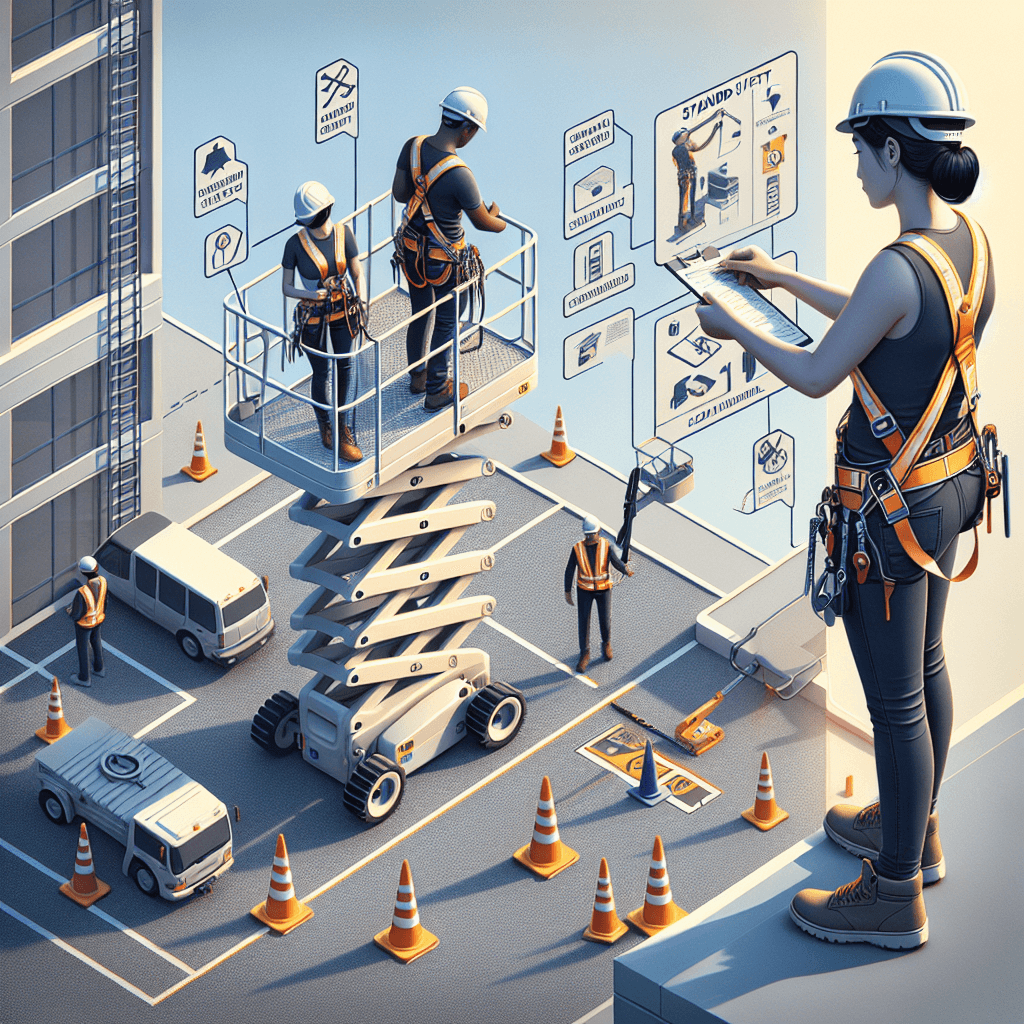

Safety related to aerial lifts is really critical. Using an airborne safety checklist is an excellent approach to begin incorporating safety into your daily life. Review our guide for a list of typical site safety dangers, knowledge on certifications, and advice on how to keep out of harm’s way to get you and your team ready.

1. Check Whether Operators Have Certifications and Training

Lift operators are limited to individuals with training and certifications. Verify that your staff members are aware with manufacturer requirements for every lift they will operate and that their certificates are current.

2. Examine every component of the lift and vehicle before use.

Before running the lift, spend some time looking over every single component. Start with the car itself by looking at fluid levels—including hydraulic, oil, petrol, and coolant. Additional items to look at include the battery, charger, wheels, tires, horns, lights, and backup alarms.

Additionally, you should make sure that all operational and emergency controls, as well as all hydraulic, air, and electrical systems, are running as they should. Search for any missing or loose components; furthermore, replace any illegible operational or instructional signs or marks. Before loading it with any employees or goods, you should also make sure the lift is operating as it should.

3. Check for Hazards in the Work Area Surrounding

Equally crucial to safe equipment is a safe work area. When working inside, you should check the ceiling to make sure it is at a suitable height and to see if there are any possible risks above. Additionally, look around the floor and surrounding area for any bumps, uneven surfaces, or other potential obstructions.

When working outdoors, look around you for any obstacles on the floor that need to be avoided or cleaned up, such as drop-offs, holes, ditches, slopes, and rubbish. Additionally, pay attention to any communication cables and overhead electrical wires that are close by. Serious weather conditions and strong winds that might put your workers in risk are other important things to be aware of.

4. Never Disregard Safety Features for Any Injustice

Moving equipment more quickly is one momentary benefit, but the higher risk of accidents is not worth it. You run the risk of operating at excessive speeds or extending the lift beyond what is safe by disabling safety systems.

5. Pay Close Attention to Your Environment

Even if cables, wires, and other conductors are insulated or are down, it’s a good idea to always regard them as electrified. To minimize potential mishaps, you should maintain a minimum distance of 10 feet from electrical wires if you are unable to avoid them entirely. Additionally, wherever feasible, steer clear of placing aerial lifts in the path of overhead risks like electricity wires.

6. Avoid Going Overweight and Reach Limits

Consider the weight carefully before putting your aerial lift into service or starting it up. Remember to account for the operator’s weight as well as the weight of the tools and supplies while doing this. To prevent tip-overs, always abide by the weight and reach limitations specified by the manufacturer.

7. Refrain from sitting, leaning, or climbing on the bucket or platform’s edge.

Guardrails are not intended for climbing or seating; instead, they are there to prevent workers from falling. Employees may trip and fall, and the lift could topple over, if this were to happen. It’s safer to lower the lift and relocate the whole machine a few feet rather than risk a catastrophic injury, even if it’s tempting to reach over to something that’s just a little bit out of reach.

8. When possible, use wheel chocks, brakes, and outriggers.

Brakes and outriggers provide stability to stop any unplanned movements in the lift or the ground. These should be used even if at first glance, the ground seems to be solid. When operating on slopes, wheel chocks are very necessary to guarantee your lift remains in position.

9. Leave the aerial lift platform free of scaffolding.

Your chance of falling will be much raised by adding scaffolding to the platform or bucket. You should steer clear of this even if the scaffolding comes within weight capacity restrictions.

Thanks to its design and possible height, scissor lifts provide a unique set of risks to be aware of. If you operate without care, their capacity to stretch vertically mixed with their ability to move horizontally might lead to issues. See everything you should do to be safe running a scissor lift here.

10. Keep Scissor Lifts Separated From Other Machinery

When using scissor lifts, be sure there are no other pieces of equipment nearby. You should always give enough of area for these lifts to function since they may topple over if they collide with another piece of machinery.

Common Aerial Lift Hazards

The heights aerial lifts attain provide harmful conditions exclusive to these equipment. For aerial lifts, for instance, severe gusts are hazardous working circumstances as they might tip over the lift. Here are a few typical risks to be on lookout:

- Employees or items falling

- Turnovers

- structural flaws

- Electrocutions

- Embankment

- Speak with ceilings, furniture, and other overhead obstacles.

Since every lift has different use and possible safety risks, knowing fundamental boom lift safety guidelines, manlift operation precautions, and how to securely operate various kinds of aerial lifts is vital. For instance, boom lifts on uneven terrain or excessively top-heavy might topple over. Though unusual, this should be kept in mind while on the field.

Training Tips for Aerial Lift Operators

As we said, only qualified and trained aerial lift operators should run these lifts. Remember that many lifts might need for separate certificates to run. Depending on a few other criteria, these credentials must be renewed at least every three years—sometimes more often. These include:

- The work environment has hazards connected to aerial lifts.

- mishaps while aerial lift operation.

- One finds an operator utilizing the elevator in the wrong manner.

- There is a novel kind of aerial lift utilized.

The next time your crew is operating boom or scissor lifts, have these aerial lift safety precautions close at hand. The greatest measures to keep you and your staff safe are always correct training, enough pre-inspections, and constant vigilance. See our library of safety stories to discover more strategies to increase work zone safety.