Scissor lifts are made out of a railed platform positioned on accordion-style legs. These expand and contract like scissors, utilizing compressed air or hydraulic fluid to lift and lower personnel and materials on the platform. Because of their huge platforms and the availability of support right beneath them, they may handle a greater platform capacity than other types of aerial lifts, such as boom lifts.

These incredibly mobile aerial work platforms allow jobsite operators to traverse through small places and across outdoor work sites, but you must consider height and lift weight before renting a scissor lift. To ensure that you hire the appropriate scissor lift, read this article to learn about the many types of lifts available and what tasks they are most suited for.

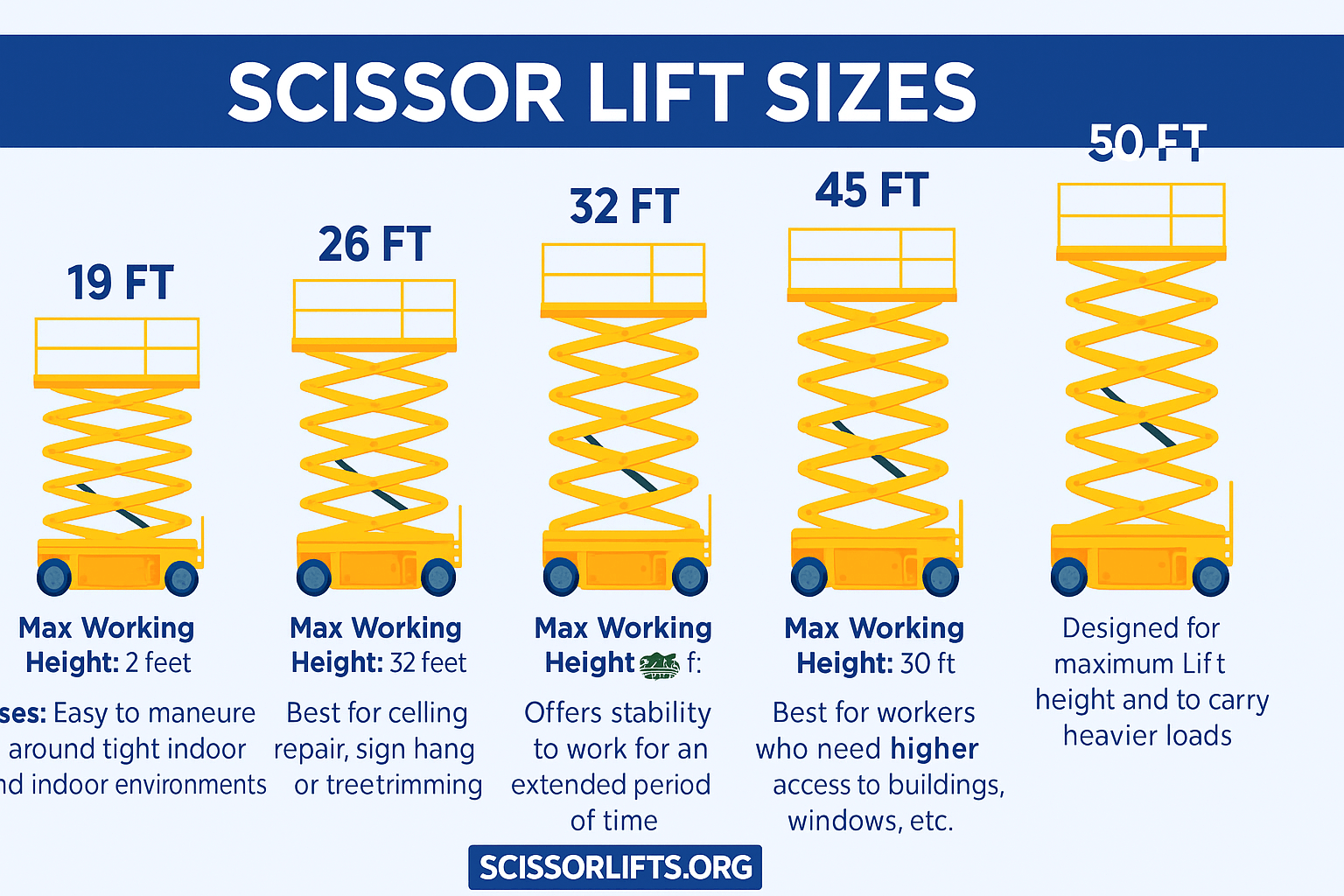

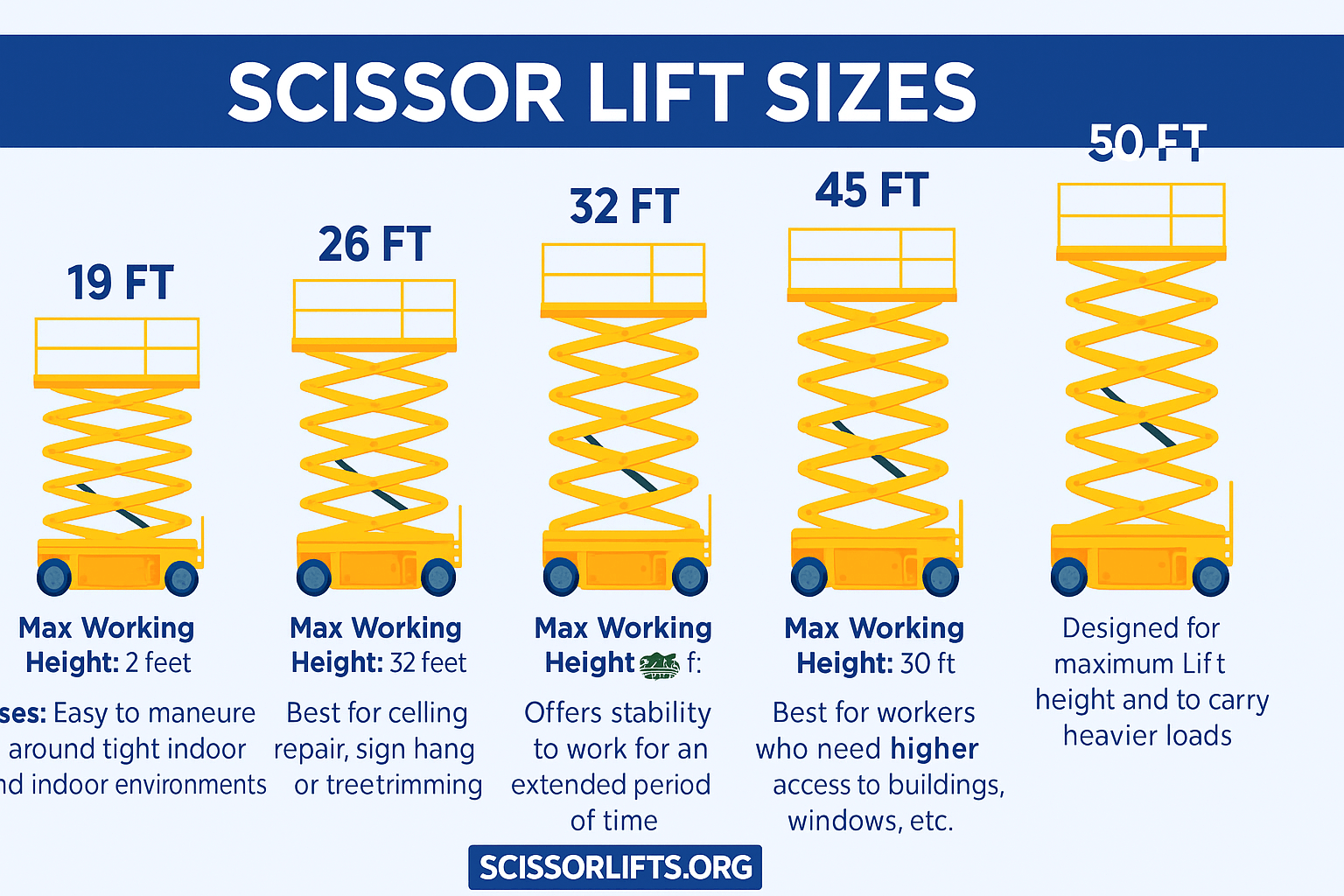

Scissor Lift Ranges

19-Foot Scissor Lift

Because of its tiny size, this scissor lift is ideal for confined spaces and other interior workspaces. This elevator is powered by electricity and does not emit dangerous emissions in interior areas. It is suitable for interior building and maintenance chores.

26-Foot Scissor Lift

The 26-foot lift is capable of handling tasks such as sign installation and tree pruning. It features a larger work platform than a 19-foot lift, so it can handle more personnel and/or goods, making it suitable for a wide range of construction and industrial operations. Its four-wheel-drive construction makes it ideal for handling tough terrain, such as hills and inclines, for off-road and landscaping work. Check lift gradeability on the spec sheet to help determine what machine you need.

The 26-foot lift is also available in a narrow-width electric form suitable for both indoor and outdoor use.

32-Foot Scissor Lift

Like the 26-foot lift, the 32-foot scissor lift is available in four-wheel drive and thin electric variants. Use this lift for industrial, construction, and maintenance purposes. The 32-foot lift has interlocking bar-style struts for long-term stability, providing workers with direct and secure vertical access to high work locations.

40-Foot Scissor Lift

The 40-foot scissor lift is available in three configurations: four-wheel drive, narrow, and wide electric types. Its design enables numerous people to reach a high elevation, making it ideal for outdoor industrial, construction, and maintenance applications.

The thin electric type is ideal for high-volume interior jobs such as wall and ceiling repair. The broad electric type can accommodate more people, making it suitable for both indoor and outdoor operations such as mural work, bricklaying, ceiling construction, and light fixture maintenance.

50-Foot Scissor Lift

The 50-foot scissor lift is excellent for large operations needing maximum lift height. Best suited for outdoor work conditions, its wider platform can accommodate numerous people and hoist heavy items, and its four-wheel drive allows for easy navigation over rugged and uneven terrain.

Factors to Consider When Choosing a Scissor Lift

When purchasing a scissor lift, you must evaluate the type of your duties and work places. This allows you to establish exactly what you want in a lift, such as how high you need to go, if you need an electric or dual-fuel type, and whether you want a four-wheel-drive lift. Consider these variables before deciding whether to hire a scissor lift for your job.

Working Height

The most apparent concern is to ensure that you account for your job’s minimum and maximum work height requirements. With a number of height options, you should be able to select a scissor lift with the appropriate vertical reach. If you discover more than one option that meets your height criteria, examine other aspects to reduce your options.

Platform Width

Another crucial factor to consider is platform size. Platforms come in regular sizes, but you can expand them. However, larger doesn’t always imply better. When you increase the platform size, you modify the lift’s center of gravity, which affects its overall performance. Make careful to update your lift calculations to reflect the change, since an uneven load might cause issues.

Type of Environment

Consider the work environment for your position. Where you need to work determines whether you need an emission-free electric lift for interior jobs, a four-wheel-drive type to negotiate rugged terrain, or a tiny lift to access hard-to-reach spots on congested work sites.

Type of Work Task

Knowing the exact activities necessary for your project, as well as the material in your load, helps you decide which lift to use. If you have to go through limited spaces, you may require a narrower or smaller elevator. If you need to repair anything from above, you might need a lift that goes higher. Consider your load’s stability, the materials used, and its center of gravity. All of these factors influence your lift decision.

Load Capacity

You must consider not only the weight of the cargo to be lifted, but also the number of personnel required on the platform. If you require numerous workers to complete your operation or need to move heavy objects, you’ll need a lift with an elevating work platform that provides ample room and stability.

Types of Scissor Lifts

Not only may you hire many types of scissor lifts for different applications, but some lifts are powered differently than others, affecting both how and where they function.

Rough Terrain Scissor Lifts

Four-wheel-drive scissor lifts are better suited for rough terrain and big loads. These diesel or dual-fuel engines can function securely in outdoor conditions and provide more horsepower for navigating difficult terrain and uneven job locations.

Electric Scissor Lifts

Electric-powered scissor lifts are ideal for interior usage since they generate no fumes and work silently, eliminating noise that can echo and be increased in confined places. Furthermore, electric elevators have a smaller footprint and perform better in compact places.

Scissor Lift Safety

The Occupational Safety and Health Administration (OSHA) enforces safety requirements for the design and operation of scissor lifts, including

- All scissor lift operators must complete required training.

- Design requirements dictate that all scissor lifts come with guardrails to prevent falls.

- To reduce falls, scissor lifts must be used exclusively on flat surfaces; only all-terrain lifts with particular gradeability may be used on uneven ground.