Scissor Lift Attachments

Scissor lifts are one of the most common and necessary tools used by multiple industries and are recognized for their feature of giving safe and easy access to the same work area but at a different height. Though, what really makes these machines’ capacity limitless is the Scissor lift attachments—industrial accessories that lead to the increase of the capabilities, the safety, and the application of the job for the almost unlimited field of work.

What Are Scissor Lift Attachments?

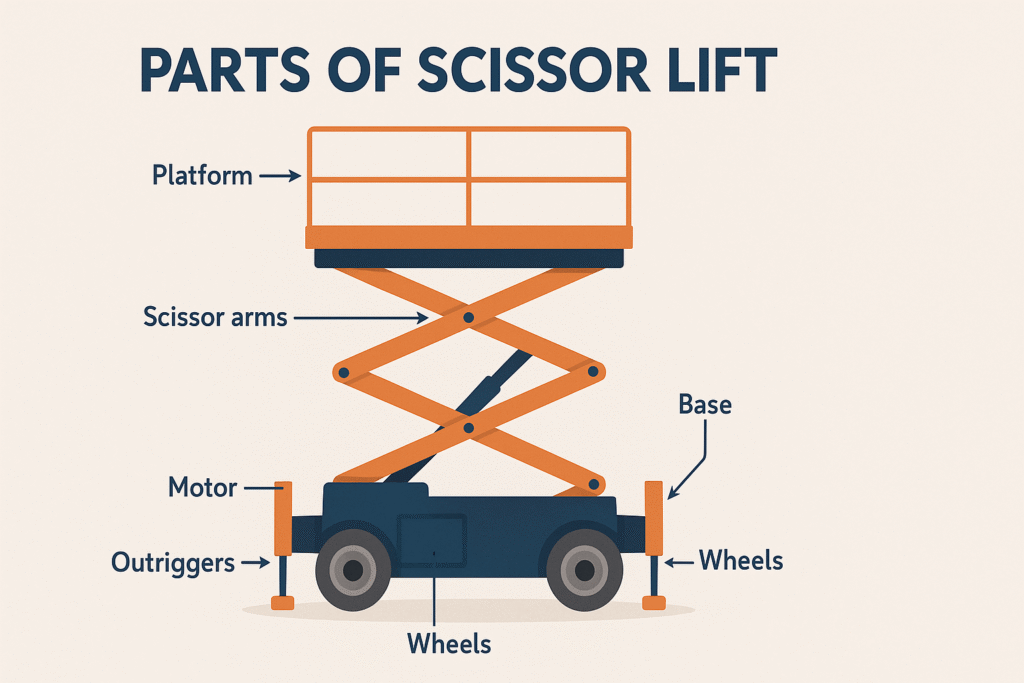

Scissor lift attachments refer to specially-made pieces or extras that aim to improve a scissor lift’s basic working capabilities. Some of these attachments may be platform extensions, material carriers, pipe racks, safety features, etc.

Such attachments enable the user to go beyond the original lift and change it into a mobile workstation that can handle trade jobs with ease such as electrical installation, HVAC, drywall, glass panel setting, and warehousing.

Why Use Scissor Lift Attachments?

Key benefits:

- Improved efficiency: It is common for attachments to be the major cause of the reduction in manual handling as well as in task downtime because the team can work more efficiently with the right tools at height which in turn will lead to saving time.

- Safety: In general, the accessories being properly designed can help in securing the materials, simplifying the space, and lowering the risk of the occurrence of workplace injuries as well as falls.

- Adaptability: The use of a thoroughly equipped lift can be multi-purpose which means that the workers will not need to have different machines on-site and the jobsite logistics will be more efficient.

- Cost-Effectiveness: It is a win-win situation for the equipment owners when they decide to put their money in the scissor lift attachments that are versatile because the money invested will bring back more returns in the long run by simply doing different jobs with the same lift.

Most Popular Scissor Lift Attachments

Selecting the right accessories can unlock new capabilities. Here are some of the most sought-after attachments for scissor lifts:

1. Deck Access Extensions

- Purpose: Increases the scissor lift platform working area, allowing the staff to reach difficult places that are out of sight of the machine without moving it.

- Typical Applications: Overhead electrical work, painting, signage, and picking goods from the warehouse stock.

- Benefits: Minimizes the need for repositioning, which in turn saves time and enhances worker access.

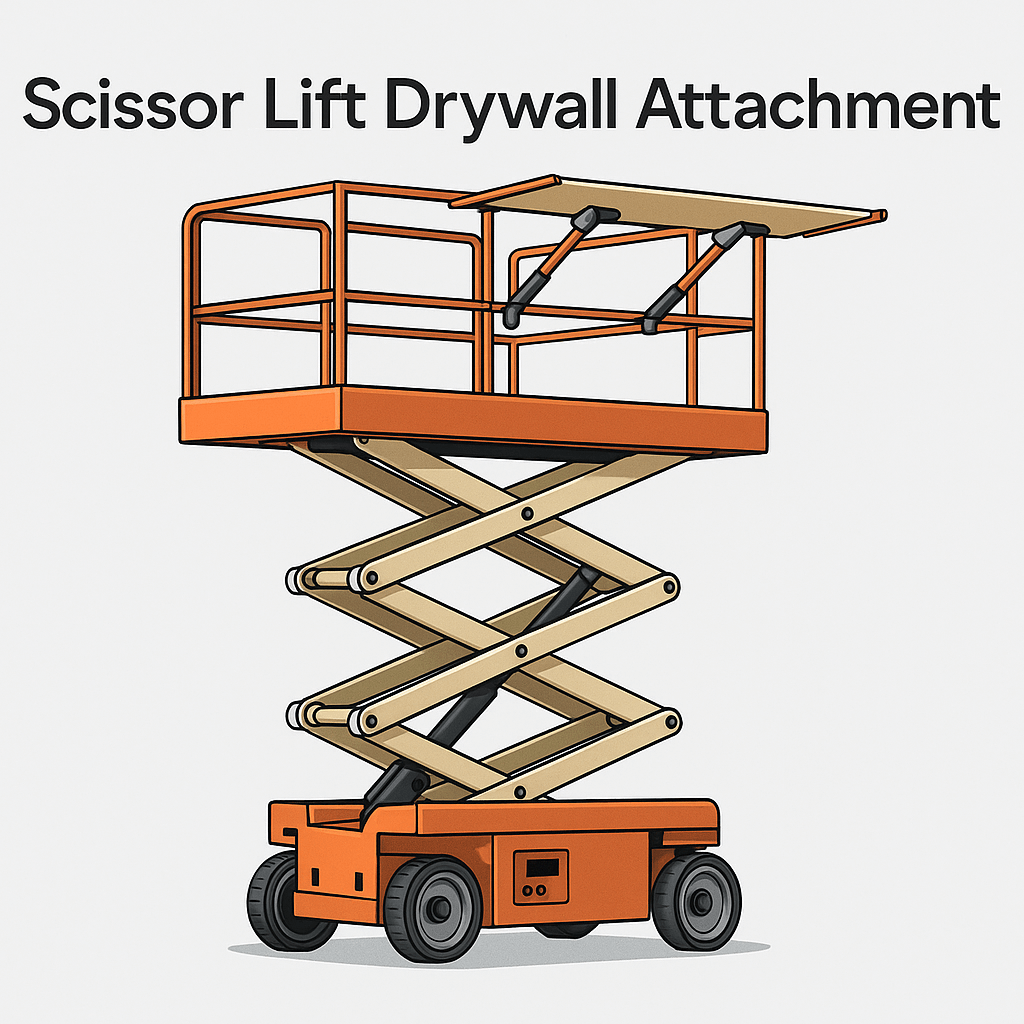

2. Material Carriers / Panel Carriers

- Purpose: External racks or trays that, in a safe way, hold panels, drywall sheets, windows, plywood, or glass for transport at a higher place.

- Features: These are devices that frequently have brackets or straps, by using which the stability of the loads is maintained.

- Benefits: Such a product elevates safety level as it makes the platform safe from various hazards, reduces the possibility of materials that are fragile getting impacted, and at the same time, diminishes drop hazards.

3. Pipe Racks and Rebar Racks

- Purpose: Parts fastened to the sides of the platform that allow pipes, conduit, or rebar to be transported in a safe manner and stored.

- Typical uses: Plumbing, sprinkler installation, HVAC, construction.

- Benefits: Makes platform space available, materials become more efficient for workers when they are installing overhead systems can take up less time thus improving their productivity.

4. Outriggers and Stabilizers

-

- Purpose: A piece of equipment that makes the support of a lift more stable when it is being used on a non-uniform surface or at the top of the allowable height.

- Advantages: A device that allows safe use and assists in meeting safety requirements in difficult surroundings.

5. Safety Accessories

- Popular types of fall protection are tilt sensors, guardrails, toe boards, enhanced harness anchor points, and platform entry gates.

- Benefits of fall protection system are that they can reduce the risk of falling, give visual and physical alerts, as well as comply with tight occupational safety standards.

6. Weather Protection & Work Aids

- Options: Machine covers, platform canopies, lighting kits, and work trays.

- Benefits: Enhances operator comfort, extends working hours, and safeguards both control and materials from the elements.

Best Practices for Choosing Scissor Lift Attachments

1. Match Attachments to Your Task

- Take a look at your application: Are you installing ductwork? Painting? Moving large panels?

- To get the most out of your work, select the tools that are specifically made for the job you are going to do.

2. Ensure Compatibility

- The first step to any scissor lift accessories will be that they are compatible with the make and model of the scissor lift you have.

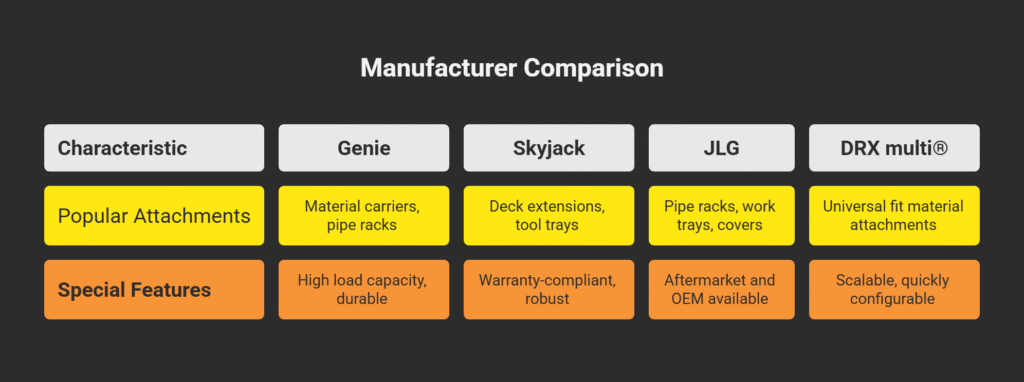

- MeWP manufacturers like Genie and Skyjack offer OEM-approved attachments that not only are they compatible with your equipment but also ensure easy operation and help with maintenance under warranty requirements.

- Every supplementary structure has its limits—the load it can be rated for up to maximum, and the user should never go beyond the specifications written by the manufacturer.

3. Prioritize Safety Compliance

- Normally accessories used in conjunction with the machine should be tested and rated for the intended load and working height.

- Refer to safety regulations and manufacturer’s instructions in order not to break warranties or create risks for the staff.

4. Versatility and Universal Fit

- Some new attachments provide a one-size-fits-all design and can be easily adjusted for pipes, panels, rebar, etc., which makes them a wise investment for rental fleets and contractors working on a variety of projects.

5. Review Load Capacities

- Every supplementary structure has its limits—the load it can be rated for up to maximum, and the user should never go beyond the specifications written by the manufacturer.

Industries & Applications for Scissor Lift Attachments

- Construction: Drywall, sheet metal, HVAC install, electrical and plumbing trades

- Warehousing & Logistics: Inventory management, rack installation, lighting maintenance

- Facility Management: Ceiling repairs, signage, window cleaning

- Manufacturing: Material movement, process line servicing

- Specialty Trades: Glass installation, acoustical panel work, fire suppression systems

Leading Manufacturers & Brands

Most trusted scissor lift manufacturers offer a wide assortment of OEM-approved attachments:

What are the most essential Attachments to improve Scissor lift safety and efficiency

1 Deck Access Extensions

- Function: Provide users a secondary raised area within the scissor lift, thus enabling a safe approach to the hard-to-reach or blocked places.

- Benefits: Works to eliminate repositioning needs, lower the chances of an accident caused by overreaching, and allow safer work at higher heights.

2 Material Carriers & Panel Carriers

- Function: Move panels, drywall, glass, lumber, or other materials that are securely wrapped on the outside, so more space and less mess would be available on the main platform.

- Benefits: Raises safety by lowering trip/fall hazards and the possibility of the materials to be damaged, at the same time, productivity is increased through easier material handling.

3 Pipe Racks

- Function: Place pipes, conduit, or rebar on the side of the platform.

- Benefits: Allows for more platform space, organizes the materials for easy access, and avoids tripping or falling items, which in turn is great for electrical, plumbing, and HVAC jobs.

4 Safety Accessories

- Guardrails & Harness Points: Besides being able to protect against falls, the enhanced guardrail systems and dedicated harness anchor points also help in complying with strict safety regulations.

- Toe Boards & Non-Slip Surfaces: Tools and materials that fall off can be averted and at the same time, better footing for operators can be ensured.

5 Lighting and Electrical Outlets

- Attachable Floodlights: The visibility that is provided for nighttime or low-light operations is greatly, thus, the accident risks are reduced almost to zero.

- Built-in Power Outlets: No more long extension cords that can cause tripping or slow down your work.

6. Tilt Sensors and Alarms

- Function: Identify a hazardous platform angle or instability and thus, alert workers before a situation gets dangerous.

- Benefits: A warning system that provides a proactive effort, thus, operator awareness is raised, and accidental tip-overs are avoided.

7. Platform Mesh/Netting

- Function: The mesh/netting keeps the platforms from falling/sticking tools, materials, or even the debris.

- Benefits: The people, who are below the platform, are protected as well as the site which is now less liable for the busy area.

8. Safety Bellows

- Function: The flexible covers that go around the scissor are the minimum that can be the risk of pinch points and injury.

- Benefits: The personnel who are nearby moving parts and especially during the maintenance or in a tight space are the ones whom the safety bellows protect.

What safety accessories are most recommended for fall prevention on scissor lifts

1. Guardrails

- Role: Primary and most essential fall prevention barrier.

- Details: According to the US Occupational Safety and Health Admin (OSHA) all scissor lifts are required to have securely fixed guardrails on every side of the platform. In addition to them being complete, unbroken, and safe, they also provide a passive, reliable form of fall protection and are generally enough in most cases.

2. Personal Fall Arrest Systems (PFAS)

- Components: Full-body harness, lanyard, and an anchorage point that is suitable.

- Purpose: By actively preventing a fall, the device is capable of stopping a fall through the worker’s arrest if the worker moves beyond the platform or is ejected. In particular, if the guardrails have been removed or under high-risk conditions, it is very important.

- Consideration: Many safety professionals are of the opinion that the use of a PFAS should be on all scissor lifts as an additional protection although it is not always mandatory if the guardrails are intact.

3. Self-Retracting Lifelines (SRLs)

- Role: Supports a harness and limits the distance of a fall moreover providing automatic tension and recoil.

- Point: The device reduces the danger of a fall due to swinging and makes the fall less fatal; it is also very convenient for use with most anchor points on modern lifts.

4. Toe Boards/Toe Guards

- Function: They keep the tools and materials from sliding off the platform, thus protecting workers below and at the same time, workers on the platform have fewer chances of tripping over.

5. Platform Mesh or Netting

- Function: The addition of mesh or netting on platforms as a further safety measure can greatly reduce the risk of small items and tools falling from elevated platforms and, thus, protect the people below.

6. Regular Inspections and Training

- Just as important as a safety device, yet necessary: In order to ensure safety, employees are required to conduct daily inspections of the fall protection equipment and guardrails. Besides that, an employer should organize a training session to instruct workers on the usage and limitations of these safety systems.

Summary:

- Keep all guardrails and toe boards in excellent condition—these are your primary fall prevention accessories.

- For the highest level of safety, wear a full-body harness with a lanyard or a self-retracting lifeline, attached to a secure anchor point.

- Use platform mesh/netting and toe boards as supplemental measures.

- Combine these physical accessories with thorough training for maximum protection against falls on scissor lifts.